Just days after taking part in the ribbon cutting for the HQ of Richardson’s Innovation Quarter, a locally grown company is setting up shop in the district.

Moving back to the city where it was founded, Adaptive3D—a maker of materials for additive manufacturing—is moving its headquarters from Plano to the Innovation Quarter. It’s a move that will quadruple the company’s footprint as it looks to add more space for manufacturing new materials.

“This new facility gives our team the capacity to serve customers more effectively around the world…to make their products stronger, lighter, greener, and more functional,” Walter Voit, founder and CEO of Adaptive3D and associate professor of materials science & engineering at UT Dallas, said in a statement. “It also positions us to take advantage of the incredible intellectual ecosystem of Richardson to help pioneer the next generations of manufactured goods and products.”

An HQ with room to grow

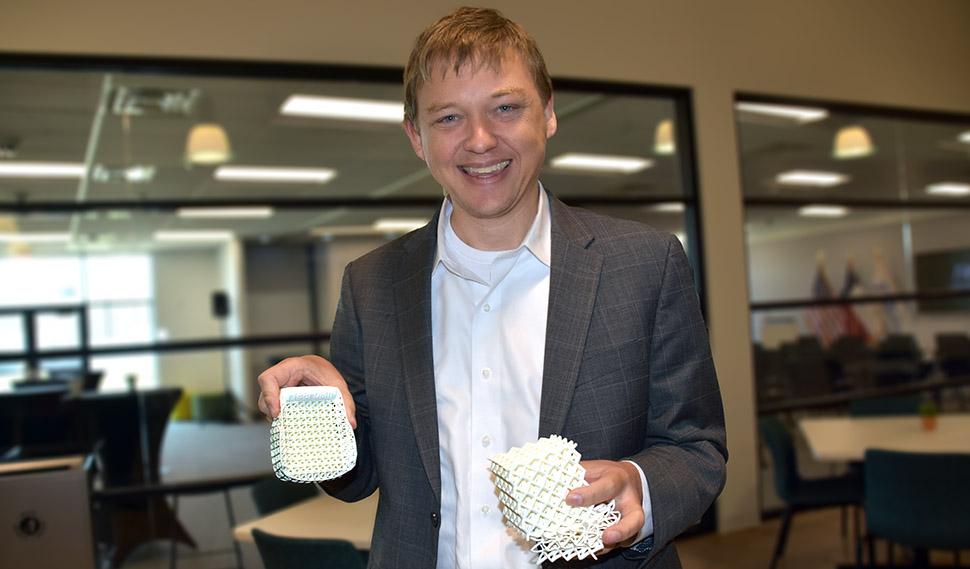

Walter Voit holds samples of mini automotive seat cushions at the IQ HQ during its grand opening in September. His company is working with OEMs to build full seat cushions that could have one of the world’s highest strength-to-weight ratios. [Photo: Dallas Innovates]

Launched in 2014 based on research conducted at UT Dallas with funding from the Defense Advanced Research Projects Agency and others, Adaptive3D is a provider of photopolymer elastomers. They are used in additive manufacturing to make durable rubber-like materials for industries ranging from consumer and healthcare to industrial and transportation.

In addition to bolstering the tech ecosystem in the Richardson IQ, Adaptive3D’s move will help it with demand via a “large deployment” of 3D printers that are able to use a new material the company is working on. Called DuraChain Materials, the photopolymers separate into two parts at the “nano level,” making them more durable.

“Our resins enable customers to topologically optimize and micro-architect their polymeric products to provide a sustainable competitive advantage now,” Voit said in 2020, following a Series B investment led by French specialty materials company Arkema Group.

Acquisitions help Adaptive3D’s parent company generate new revenue

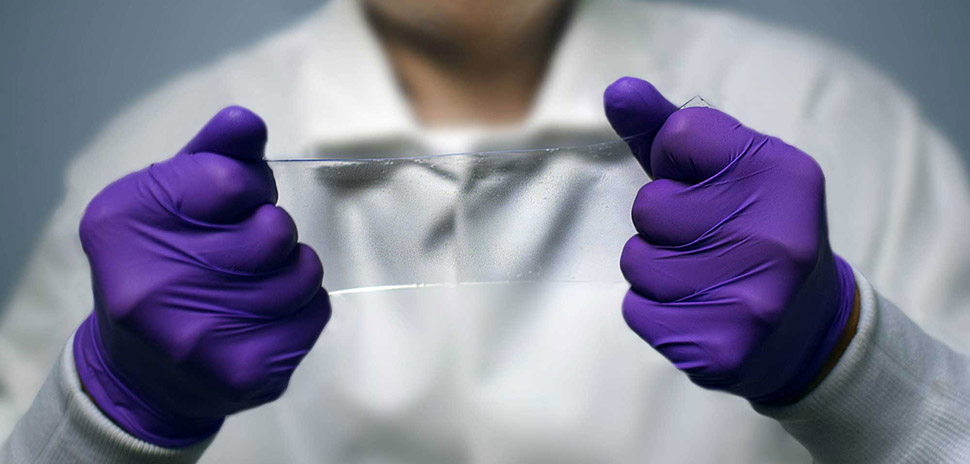

Adaptive3D focuses on creating strain-tolerant materials used for additive manufacturing. [Photo: Courtesy Adaptive3D]

After gaining backing from DSM Venturing, Applied Ventures, the founding family of Texas Instruments, and others, Adaptive3D was acquired by Boston-based 3D printing solutions Desktop Metals, which has also been growing. The companies said at the time that the move would advance publicly traded Desktop’s vertical integration strategy by expanding its portfolio of materials capabilities.

According to its second quarter financial results, Desktop said it expects to generate $260 million in revenue this year—a 131% increase from the previous year. The company attributed part of that growth to “contributions from acquisitions” like Adaptive3D.

Adaptive3D adds to the growing Innovation Quarter

Richardson’s Innovation Quarter [Photo: Michael Samples]

The culmination of years of planning and work, Richardson’s Innovation Quarter is a 1,200-acre development situated between Campbell Road to the north and Apollo Road to the south along a stretch of land known as the Telecom Corridor. Anchored by the 27,500 square-foot IQ HQ, which hosted its ribbon-cutting ceremony last week, the project is aimed at bringing together players from tech startups to established international firms, university researchers, and public stakeholders to make the city a global player in the ecosystem.

Richardson Mayor Paul Voelker said the IQ can provide a place for building a business or commercializing the research coming from UT Dallas and other institutions in North Texas. The IQ aims to attract hundreds of small companies and startups that could eventually turn into unicorns or go public, rather than focusing on incentivizing one or two big-name companies to set up shop in the city.

The IQ HQ will house the city of Richardson’s Office of Economic Development and Office of Strategic Initiatives, along with a number of research centers focused on things like smart mobility, applied AI, and machine learning under the umbrella of the Centers for Emergent Novel Technology at the Innovation Quarter.

“This move also signals the strength and importance of partnerships with key academic institutions like UT Dallas and the role they play in fostering the collaborative creation of future-ready technologies within the IQ,” Volker said in a statement.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.