Dallas-area startups just keep on innovating—and getting acquired. Today’s big winner: Adaptive3D Technologies, a leading provider of elastomeric solutions for additive manufacturing. It’s been acquired by Boston-based Desktop Metal Inc. and will become its subsidiary in a deal announced today.

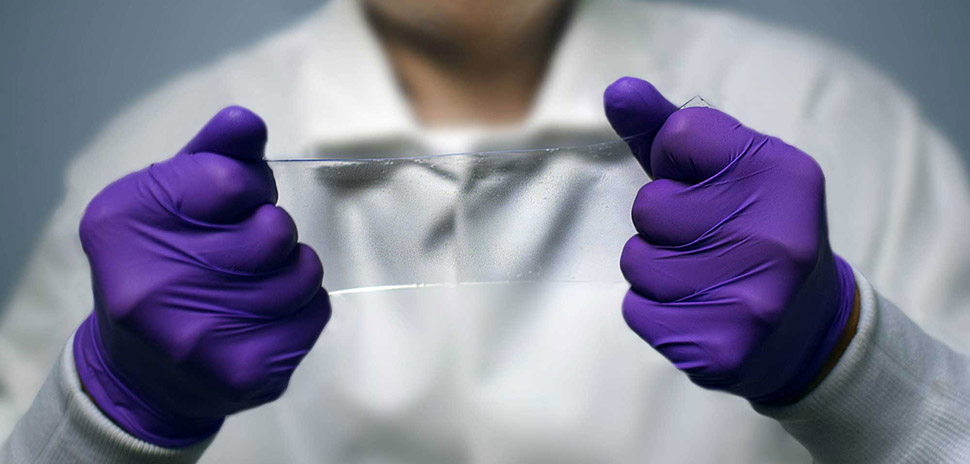

Adaptive3D creates tough, flexible plastics and rubber-like materials one layer at a time through additive manufacturing. Using 3D printing, they build things layer by layer to develop materials for everything from shoes to airplanes to smart orthotics. The company’s solutions serve customers across a wide range of consumer, healthcare, industrial, transportation, and oil and gas markets.

Adaptive3D was launched by President and CEO Dr. Walter Voit, a UT Dallas associate professor of materials science and engineering, through UTD’s Venture Development Center. Dallas Innovates wrote about his company’s Series B investment last October, and featured its emerging tech in our 2021 Resilience Issue.

Dr. Walter Voit [Photo: UTD]

“I’m very grateful to the McDermott family and to the leadership at UT Dallas for creating an intellectual environment that breeds success,” Voit said in a release. “Success really is luck—you’ve got be in the right place at the right time and be lucky. They’ve created that right place and right time.”

In a video, Voit makes his products sound deceptively simple, calling them “a material that when you stretch it, it will bounce right back.” He says what really differentiates his material is the chemistry.

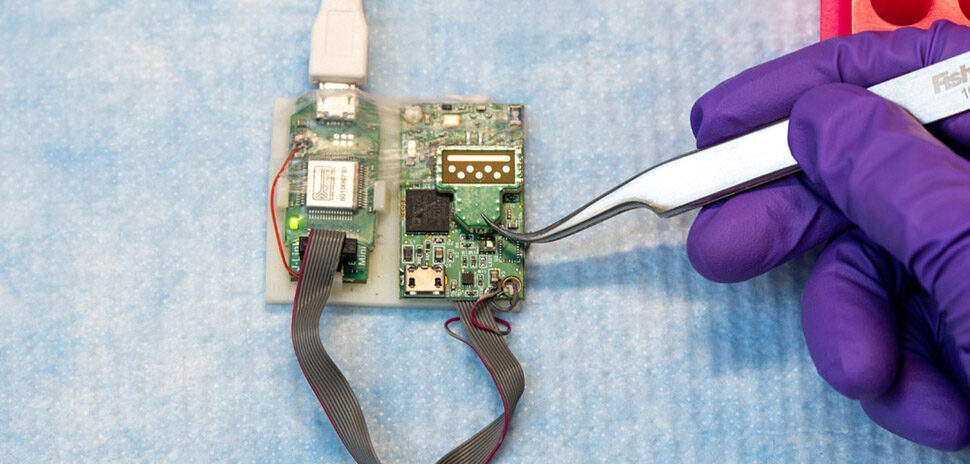

Adaptive3D focuses on creating strain-tolerant materials used for additive manufacturing. [Photo: Courtesy Adaptive3D]

“We’ve discovered some new ways to polymerize materials that make them stronger, make them tougher, make them more tear resistant,” Voit says in the video. “This process that’s based on Texas Instruments’ huge investment in DLP chips allows us to precisely pattern light to make just the plastic we need. So that we can make parts lighter, cheaper, more sustainable—greener—and ultimately lower costs.”

Why did Desktop Metal acquire Adaptive3D? Let them count the resins why:

“Adaptive3D has the best photoelastomer resins in the world,” said Ric Fulop, founder and CEO of Desktop Metal, in a statement. “Combining Adaptive3D’s patented and superior elastomer materials with our printers, such as the Xtreme 8K (mass production printer)…will accelerate the adoption of additively manufactured solutions for high-volume, end-use elastomeric parts and products.”

The acquisition advances Desktop Metal’s vertical integration strategy, the company said, allowing it to expand its portfolio of materials capabilities.

Voit said the acquisition will help Adaptive3D, too, by extending its strong relationship with EnvisionTEC and “enabling us to accelerate our growth into the $129 billion elastomer and flexible foams market just waiting for high-volume, additive manufacturing elastomer capabilities.”

Adaptive3D will operate as a wholly owned subsidiary of Desktop Metal, and Voit will continue leading it as CEO from the company’s Plano HQ, UTD confirmed.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.