Dallas-based Adaptive3D, which calls itself the premium supplier of Additive Manufacturing polymer resin, has secured a round of undisclosed Series B financing.

The funding was led by the Arkema Group, a France-based producer of specialty chemicals, and had support from West Pharmaceutical Services, Clear Fir Partners, and current investors, such as Applied Ventures and the founding family of Texas Instruments.

According to Adaptive3D, Arkema and West Pharmaceutical Services represent potential end points of an Additive Manufacturing ecosystem. Additive Manufacturing (AM), commonly known as 3D printing, essentially describes technologies that can build 3D objects by depositing layer-upon-layer of material.

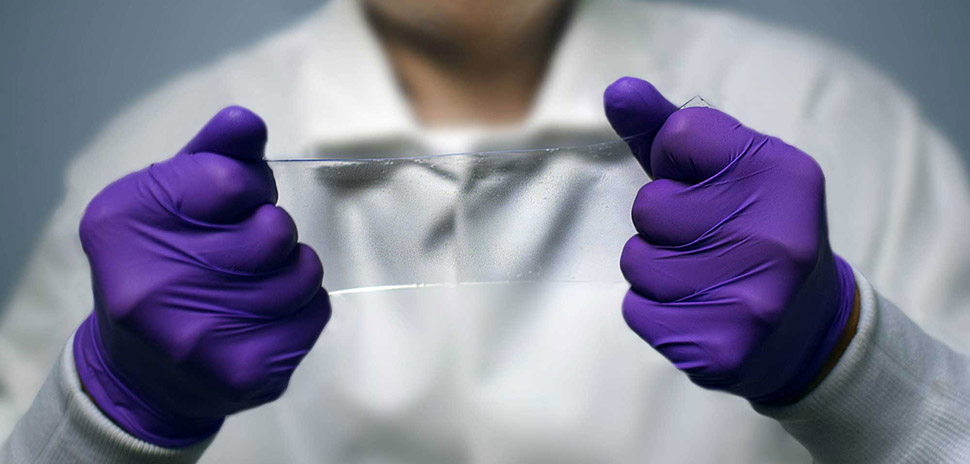

Adaptive3D sells photopolymer resins, which are said to enable Additive Manufacturing of “tough, strain-tolerant, tear-resistant rubbers.” Arkema itself is a leader in supplying specialty materials that can enable sustainable solutions to manufacturing technologies.

“Adaptive3D photoresins, based on Arkema materials and now validated in the market, further our customer-focused mission to reach into new application spaces with 21st century materials,” Arkema’s Senior Director of 3D Printing Sumeet Jain said in a statement. “Adaptive3D delivers compelling materials properties with an ease of printing and post processing—a great step forward for the whole additive manufacturing field.”

Per a news release on its website, Adaptive3D plans to use the capital to further its mission of “providing materials to enable 21st century manufacturing.” The startup uses cutting-edge technology and optimized materials to enable high volume Additive Manufacturing.

But, according to Adaptive3D, AM has a legacy in rapid prototyping, in which the properties of materials were secondary to form and fit.

To Adaptive3D, a material’s properties need to be a predominate driver and limiting factor, especially as AM transitions into more true manufacturing. Properties often “fall woefully short through the industry,” which can limit the applications and markets the platform can be used for.

Adaptive3D wants to revolutionize what AM promises to deliver by “enabling customers to produce flexible end parts and products at scale.”

The startup’s solution is photopolymeric resin, which is optimized for producing end use parts and products.

“With high tear strength, high elongation and market leading toughness, these materials are the perfect solution for true Additive Manufacturing of flexible elastomeric parts,” the startup says on its website. “In particular, Adaptive3D’s resins excel as the 3D printed version of elastomers such as rubbers, polyurethanes and silicones. With high elasticity and a range of Shore A durometer resins, Adaptive3D has become the leader in elastomeric solutions for Additive Manufacturing.”

Today, Adaptive3D is offering AM polymer resins and specialty polymers to industries like healthcare, transportation, and oil and gas, and has formed partnerships with Fortune 500 companies such as Halliburton and Honeywell.

Founded by inventor Walter Voit, the president and CEO, in 2014, the company is now known as a premium supplier of photopolymer resins. In particular, Adaptive3D leads in the area of damping materials, rubber like 3D printable materials, and low-cure stress photopolymers.

At The University of Texas at Dallas, Voit is a professor who helms the Advanced Polymer Research Lab, leading a team that explores the fundamental thermomechanics of smart polymers. With research that spans flexible electronics, 3D printing, energy harvesting, and homeland security, the lab is making great strides in the field.

Among their results include ultra-comfortable earpieces (with Syzygy Memory Plastics), cortical and peripheral probes (wired and wireless), smart orthotics, and prosthetics and cochlear implants. Voit, the author of more than 100 manuscripts, also holds multiple patents.

“Challenging the aging model of injection-molded rubbers and polyurethanes, Adaptive3D is now scaling production and distribution to deliver shelf-stable, print-stable, one-part photoresins that yield superior, manufactured end parts,” Voit said in a statement. “Our resins enable customers to topologically optimize and micro-architect their polymeric products to provide a sustainable competitive advantage now.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.