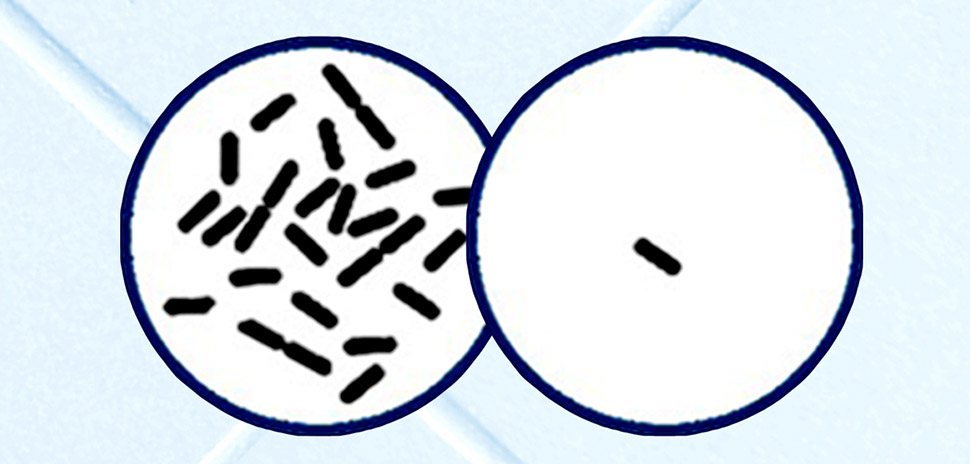

Aereos Inc, a global aircraft solutions provider, has received the test results for antimicrobial silver ion technology built into its high-touch interior products. An independent microbiological testing lab certified that the tech is more than 99.8 percent effective against microbes.

This is a first in the aviation industry, according to Dallas-based Aereos.

One of Aereos’ five divisions, Aereos Interior Solutions (AIS), achieved the high level of antimicrobial effectiveness. When tested over a 24-hour period, the aircraft interior parts were shown to have long lasting protection against harmful microbes when equipped with the antimicrobial layering technology.

The tech is from BioCote, a UK-based supplier of antimicrobial technology. When manufactured into products, BioCote says its antimicrobial additives are able to protect against microbes like bacteria and mold.

Aereos used it for an aircraft’s high-touch cabin and lavatory parts, like tray tables and toilet seats.

This is incredibly significant considering the interior areas are some of the dirtiest on an aircraft—and during a global pandemic, that’s evermore important.

“Our interior parts are the first line of defense to protect passengers and crew during their flight by providing a layer of protection not available in the market until now,” David Baker, a partner at Aereos, said in a statement. “It only makes sense for airlines to replace older parts with ones that add layers of protection at no incremental cost (and significantly less than OEMs).”

The news follows many popular airlines, like locally based American and Southwest, announcing new cleaning procedures to further protect passengers from COVID-19. Some are equipping aircrafts with air filters that recycle cabin air every 2-4 minutes, while others are using electrostatic spraying solutions for continuous protection.

Aereos’ solution attacks a virus and other harmful microbes where they accumulate on high-touch surfaces, the company said.

The team calls its new antimicrobial technology the “missing link” between the two solutions on the market today: cleaning surfaces prior to allowing anyone on board and using HEPA air filters to purify the air.

According to Aereos Interior Solutions, it is able to reduce harmful microbe growth on surfaces during the flight, which adds “a layer of protection not currently available in the market.”

The long-lasting protection doesn’t wear or wash off, Aeros said, and it reduces cross-contamination from surface to surface. The tech is also said to reduce odor and staining that causes microbes on high-touch interior surfaces.

In addition to being recently proven effective, the technology is now certified by the Hazard Analysis Critical Control Point and approved as food contact safe by the Food and Drug Administration, per a news release.

“We are pleased to play a part in helping airlines build passenger confidence by introducing a line of antimicrobial high-touch aircraft parts that work 24/7, during and even between traditional cleanings by the airlines,” Baker said. “Our introduction to the market was a combined effort of Aereos with our innovative proprietary processes and technologies developed over decades by highly skilled engineers in concert with BioCote’s experienced team, leveraging 25 plus years of success in the antimicrobial field.”

Aeros itself is a global provider of parts and services to commercial airlines, MRO, OEM, and military customers. Its experts focus on component repair and overhaul, FAA-engineered repair solutions, precision manufacturing, and custom antimicrobial interior products throughout its five divisions: Atlas Aerospace, Airline Components Parts, EulessAero, Aereos Interior Solutions, and Aereos Defense.

Baker and his business partner, William Montgomery, established Aereos Interior Solutions last year with the intent to provide airlines with a cost-effective alternative to the high cost of aircraft interior parts.

“Our passion for design and manufacturing of aircraft interior parts realized its humble beginnings many years ago when Aereos Interior Solutions was producing parts under our EulessAero division,” Baker told Dallas Innovates. “Leveraging our skilled team of engineers and craftsman was the beginning of a division that would later have a profound contribution to the industry for which we are so passionate.”

When COVID hit, the team knew they had to leverage what they did best to help airline customers stay in the air—and safely. That’s when the new line of antimicrobial aircraft interior parts was born.

Baker says he’s excited to be playing a part in building passenger confidence in flying. Now, the team is collaborating closely with airlines around the world to incorporate antimicrobial parts into fleets at no incremental cost.

“Like the Wright brothers who began their work in a bicycle shop in Dayton, Ohio and spent many months testing their theories before realizing their goal, we are excited to have been able to do what we do best to help our industry and its customers,” he says.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.