Dallas-based Texas Instruments introduced a new sensor today that can help smart factories operate with more precise, real-time control.

TI says its new TMAG5170 “is the industry’s most accurate 3D Hall-effect position sensor.” Engineers who use it can achieve ultra-high precision at speeds up to 20kSPS (kilo samples per second) while using at least 70 percent less power, the company says.

The sensor also provides integrated functions and diagnostics to maximize design flexibility and system safety.

“Smart factories have an increasing number of highly automated systems that must operate in a more integrated manufacturing flow while simultaneously collecting data to control processes,” said Noman Akhtar, senior research analyst at Omdia, in a statement. “3D position-sensing technology that delivers higher accuracy, speed, and power efficiency is essential for automated equipment to quickly deliver precise real-time control for increased system efficiency and performance while reducing downtime.”

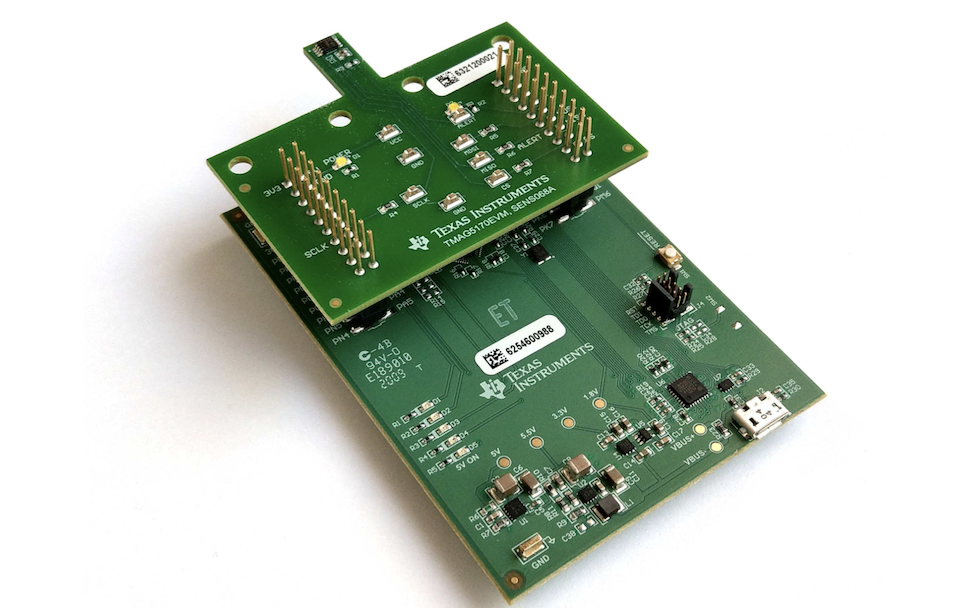

TMAG5170 Evaluation Module [Image: Texas Instruments]

Part of a new TI sensor family

The TMAG5170 is the first device in a new TI family of 3D Hall-effect position sensors targeting a range of industrial needs, from ultra-high performance to general purpose, TI says.

Crunching the numbers

TI says the TMAG5170 “is the industry’s first 3D Hall-effect position sensor to provide a low 2.6 percent full-scale total error at room temperature.”

It also features best-in-class drift of 3 percent total error—which is 30 percent lower than the next closest competitor—along with at least 35 percent lower error than comparable devices in the presence of a cross-axis field, the company says.

By delivering higher accuracy, the new sensor eliminates the need for end-of-line calibration and off-chip error compensation, which simplifies system design and manufacturing.

The sensor’s integrated functions reduce the system’s processor load by as much as 25 percent, enabling engineers to use general-purpose microcontrollers (MCUs)—which can help minimize overall system costs.

Smart diagnostic capabilities

Safety is another selling point of the new sensor. The TMAG5170 features a unique set of smart diagnostic capabilities—including checks for communication, continuity, and internal signal path—along with configurable diagnostics for the external power supply, magnetic field, and system temperature. This allows for customized safety schemes at both the chip and system level, resulting in long-term reliability and lower design costs, TI says.

To learn more about how 3D Hall-effect sensors work, check out this interesting TI post.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.

![TI's new radar sensor gives automotive engineers more tools that can fuel vehicle innovation. [Source image: Texas Instruments]](https://s24806.pcdn.co/wp-content/uploads/2022/01/TI-radar-sensor_courtesy-970x464.jpg)