If you’re using a modern electronic device, Tuesday’s the day to say thanks to Jack Kilby and Dallas-based Texas Instruments: It’s the 65th birthday of the integrated circuit.

To celebrate “Jack Kilby Day,” TI is honoring the engineer and innovator who pioneered the integrated circuit—also called a chip — in 1958.

His groundbreaking invention laid the foundation for modern electronics, and its impact affects nearly every aspect of our lives. His innovation can be found in nearly every piece of electronics we use today—from smartphones to computers, televisions, and even our cars and home appliances.

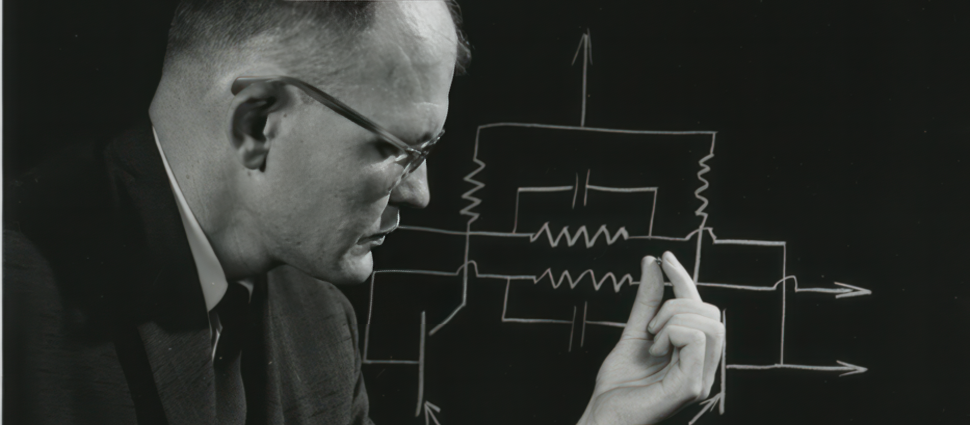

Building on his lifelong passion for electrical engineering, Kilby invented the first working integrated circuit in 1958 in Dallas.

Originally the size of a nickel, technological and manufacturing innovation now enables the production of chips as small as a flake of pepper, TI said.

Kilby won the Nobel Prize in 2000 for developing the integrated circuit, in addition to the National Medal of Science and the National Medal of Technology.

Kilby held more than 60 patents including one for the portable electronic calculator, which was invented in 1967 by Texas Instruments.

Kilby’s invention has become omnipresent. It’s found in every aspect of our lives—from making cars safer and more autonomous to advancing renewable energy technology.

Jack Kilby’s legacy

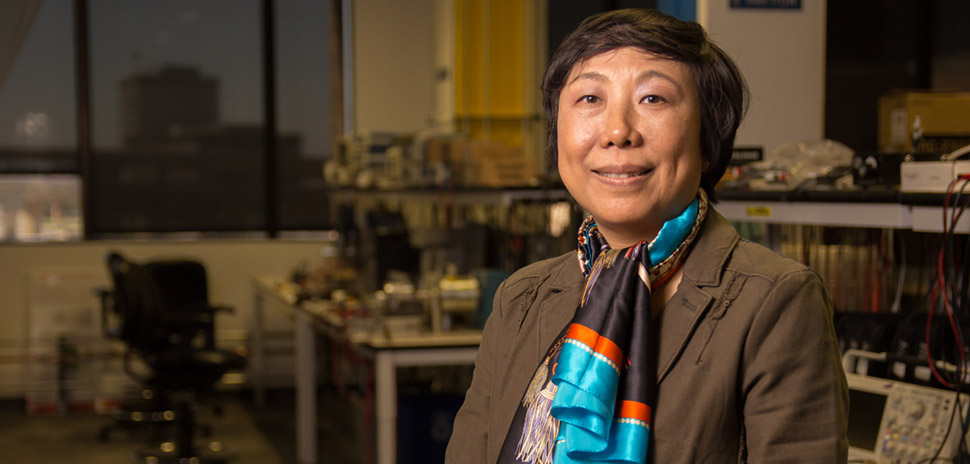

Xiaolin Lu in Ti’s Kilby Labs. [Photo: Courtesy TI]

TI commemorated the 50th anniversary in 2008 by opening Kilby Labs at the company’s Dallas campus. The research and development facility is tasked with creating new ways to use the chip.

Xiaolin Lu, TI Fellow and an R&D director at Texas Instruments, said that the invention truly changed the world.

“When Jack Kilby invented the first integrated circuit in 1958 at Texas Instruments, he couldn’t have known that it would someday enable safer cars, smart electric meters, ultrasound machines that fit into your pocket and so many more essential applications we rely on today,” Lu said. “Jack Kilby’s invention allowed humans to explore space and fly to the moon, allowed engineers to miniaturize computers that were once the size of a room to fit into the palm of a hand, and even enables the deaf to hear.”

Lu, who we profiled in 2019 as a Dallas Innovates Innovator, said that Kilby’s legacy continues via TI’s work.

“While it’s been 65 years, Jack Kilby’s legacy lives on through our company’s passion to create a better world by making electronics more affordable through semiconductors,” she said. “Our employees’ innovations continue to propel analog and embedded processing semiconductor technology into the future—at the heart of which is some of the technology we utilize every single day. In fact, nearly every device that plugs into a wall or contains a battery has a semiconductor in it, and there’s a good chance it’s a TI chip.”

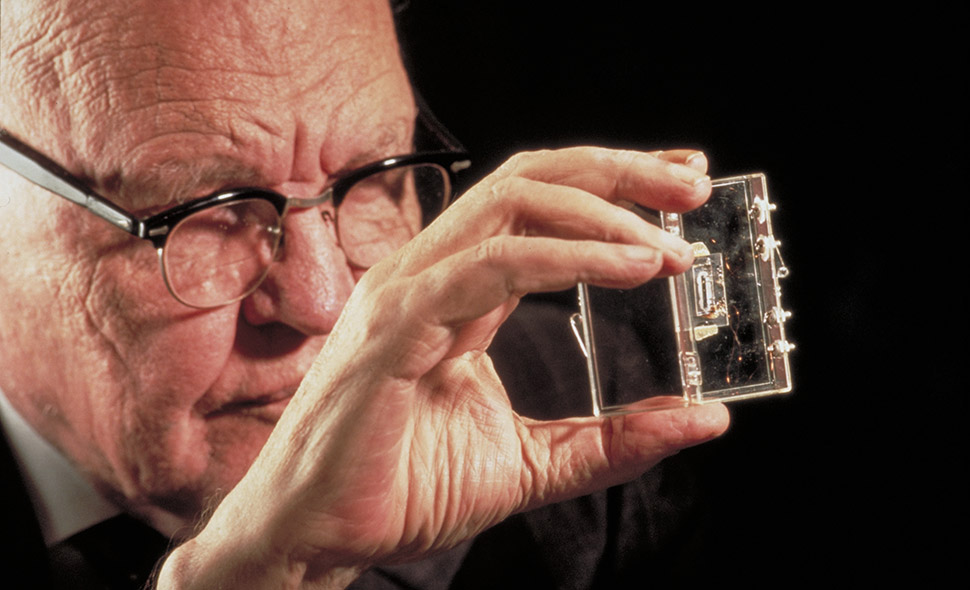

Jack Kilby [Photo: Texas Instruments]

What’s next at TI?

“In today’s era of increased electronics, TI is excited to continue help shape the future,” the company told Dallas Innovates. “We’re dedicated to making semiconductor technology that can enable smaller, more efficient, reliable and affordable innovations—making it possible to empower the many electronics consumers use and trust, every day.”

For instance, TI said that today’s vehicles are packed with more chips than ever before, from bumper to bumper and roof to wheels.

“These days it’s common for modern vehicles to contain between 300 to 400 chips, while electric vehicles can even surpass a thousand. Additionally, chips are enabling energy advancements in areas such as solar energy for homes, reliable EV charging, and seamless energy distribution and storage for when needed most,” TI said.

Looking ahead, TI says that with the growing need for chips in electronics, for advancements such as robotics and vehicle electrification, the company will continue to invest in its manufacturing capacity.

“Doing so will help us provide our customers with greater assurance of supply, so they can bring to consumers affordable and efficient electronics to power their everyday lives,” TI said.

“Finally, with its friendly business climate, skilled talent base and strong network of community partners, we believe North Texas will continue as an intrinsic part of TI’s journey forward,” TI added.

Last fall, in an interview with Dallas Innovates for our 2023 magazine, Xiaolin Lu told us that “during the past year, we learned to be more flexible and creative in the ways we collaborate and work efficiently.”

She said that Texas Instruments and Kilby Labs research centers have been and will continue to initiate new projects in the medical, health, and wellness industry by developing and applying sensing, processing, and connectivity ICs—both analog and digital to enable more applications.

“One of the projects we are currently working on is a smart analog sensing interface,” she said. “Once finalized, it will more effectively and efficiently sense and analyze air quality to detect risks to human health. It will also be used in fire-alarms and other safety devices. Looking ahead, we will have additional silicon solutions available to address a variety of applications in the medical, health and wellness industry.”

Aiming for more sustainable manufacturing

For this year, Lu said that TI has an exciting, internal manufacturing strategy that provides greater assurance of supply to support the future growth of semiconductors in electronics for decades to come.

“Reducing energy and greenhouse gas emissions through upgraded factory tools, abatement technology and using more alternative energy continues to be important,” she said. “TI has a long-standing commitment to responsible, sustainable manufacturing.”

Additionally, she said that advanced semiconductor manufacturing processes improve production efficiency while minimizing costs.

“We operate with a passion to create a better world by making electronics more affordable through semiconductors,” she said.

“This year, we are back to a normal working environment but our ability to tackle unexpected conditions, such as a pandemic, has improved greatly,” Lu said in the interview. “In Kilby Labs, we are laser focused on the next era of semiconductor technologies.”

She said Kilby Labs works closely with the company’s manufacturing organization on a variety of smart manufacturing projects by leveraging TI products to assist in more efficient, high-quality and affordable semiconductor production processes.

“As for myself, I continuously enjoy what I do as an engineer and appreciate any opportunity to promote diversity and inclusion in the technology field as a senior engineer,” Lu said.

You can find out more about Jack Kilby Day on TI’s social media pages.

Last year, we told you about TI breaking ground on new semiconductor plants in Sherman, which could create up to 3,000 jobs, and updated you with more on the facility in May. Its new semiconductor plant in Richardson just achieved LEED Gold certification, the first for a U.S. wafer fab.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.