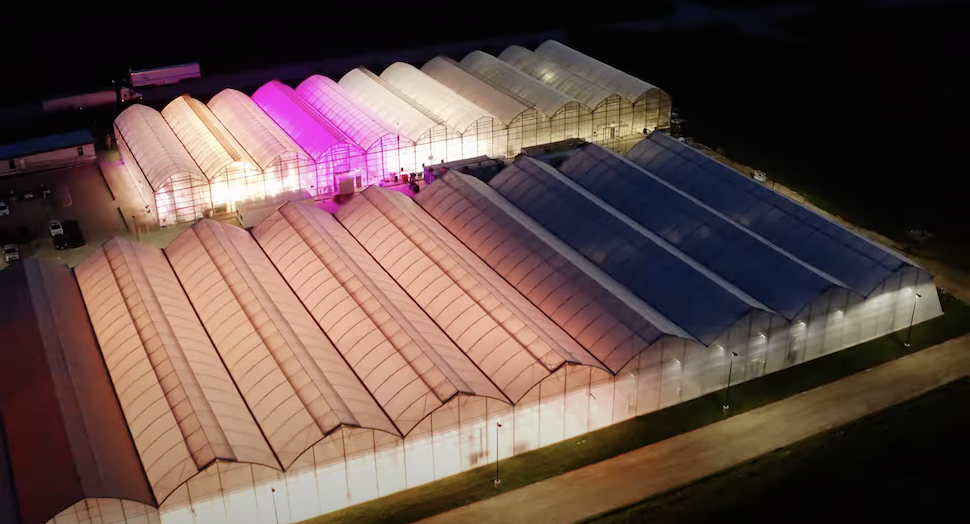

After breaking ground on it last year, Eden Green Technology has opened its first dedicated commercial vertical farming facility in Cleburne, south of Fort Worth.

The local “next-generation indoor agriculture company” announced the opening of its new, two-acre vertical greenhouse today. It was built alongside Eden Green’s existing 40,000-square-foot pilot facility and is the first phase of a planned $47 million vertical farm.

“The demand for locally grown healthy produce is at an all-time high. The last few years have seen tremendous investment in the industry at large and in Texas specifically,” Eddy Badrina, Eden Green Technology CEO, said in a statement. “We’re proud to have been one of the earliest—and now one of the largest—leaders in the space, creating fresh food and new opportunities for workers.”

New greenhouse can grow 1.8M pounds of produce annually

Eden Green vertical farm in Cleburne. [Video still: Eden Green Technology]

Eden Green’s sprawling new vertical greenhouse will be able to grow 1.8 million pounds of produce annually in just 62,500 square feet of growing space.

The company is currently constructing Phase Two of its Cleburne operations. The $31 million expansion on a three-acre site will add 125,000 square feet of growing space, allowing the company to triple its total production to more than 5 million pounds of produce annually. Once completed, the second phase facility is expected to employ around 50 workers.

Eden Green’s greenhouses can produce 11 to 13 harvests per year

Utilizing the company’s proprietary microclimate environments, lighting solutions, and hydroponic vine systems, Eden Green says its vertical greenhouses are able to produce between 11 and 13 harvests per year and grow more than 200 products.

The company says it’s building a decentralized nationwide “mesh network” of vertical greenhouses to help shorten supply chains, eliminate food waste, and reduce environmental impact. Last year the company said it projects having 20 greenhouses around the globe by 2024.

“As we continue to develop partnerships across the country, we will remain focused on acting as responsible stewards not only to our investors, but our communities and the environment,” said Badrina, who joined the company in 2019.

10% of weekly harvest to be donated to nonprofits

Eden Green vertical farm in Cleburne. [Video still: Eden Green Technology]

Funding for the new facility, which the company said uses 99% less land and 98% less water than an equivalent yield on a soil-based farm, came in part from a $12 million investment Eden Green Technology raised from existing backers around the time it broke ground last March.

With the goal of offering scalable, sustainable solutions, Eden Green Technology said its new commercial facility will help producers, retailers, and suppliers expand their educational offerings, adding that due to its “established relationships with local and national distributions channels,” nearly all of the produce from the vertical farm is already spoken for.

Eden Green Technology also said that, as part of its business model, 10% of weekly harvest from its facilities are reserved and donated to local nonprofits. In the case of the newest facility, nonprofits receiving reserved food include Veterans Produce, OurCalling, and the Fossil Rim Wildlife Center.

Symbolizing a ‘paradigm shift’—and nearing a Series B funding round

“The fact is that land, water, and energy aren’t being used efficiently to produce and distribute our food, and if we want to be responsible shepherds for future generations, we need to embrace solutions that maximize productive yield and profitability using our limited resources,” Badrina said when Eden Green Technology broke ground on the greenhouse. “This facility symbolizes a paradigm shift for how capital investment is being leveraged to do the most good where it’s needed.”

Approaching a Series B funding round, Eden Green Technology said it’s continuing to grow. As part of that effort the company has added Matt Hemsley, CEO of Piper Heartland Healthcare Capital, to its board of directors.

“Eden Green is delivering upon the promise of profitable indoor growing in an urban-adjacent environment—a challenge as yet unmet by other competitors,” the company said in a statement, adding that its facilities are “sustainable, scalable, and grow the freshest, safest and healthiest produce available.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.