Like speed limits on a highway, signal latency can slow down innovation—and put things like our electricity grid in catastrophic danger. But last week Texas Instruments (TI) accelerated what’s possible with a new family of SAR ADCs—a breakthrough in high-speed data converters with up to 80% lower latency than competitive devices at similar speeds.

You probably didn’t gossip about SAR ADCs at your last lunch date—unless you’re an electrical engineer—but they’re vitally important to keeping industries flowing smoothly, efficiently, and safely.

Designed for a lightning strike—and more

What makes SAR ADCs so vital? First, because ADCs are almost everywhere.

“ADCs are found in most every piece of electronic equipment and are often used to help a system measure voltage and current,” Matt Hann, TI’s product line manager for high-speed data converters, told Dallas Innovates. “If an overvoltage or overcurrent event occurs, the ADC can send a signal to shut down the system to prevent damage.”

Hann told us this is especially important in a system like grid infrastructure, where lightning strikes can cause powerful grid system failures. TI’s new family of SAR ADCs are all about beating those lightning strikes before they can wreak havoc in systems—along with all kinds of benefits that come from increasing speed and lowering latency, or time delay.

That’s huge, because SAR ADCs ( successive-approximation register analog-to-digital converters) are key in enabling high-precision data acquisition in industrial designs.

Best in noise performance and power use

TI’s new ADC3660 family is the first of its kind to provide both excellent noise performance and low power consumption at their sampling rate, Hann says. Competing ADCs are on the market could reach similar speeds, but only at the expense of noise performance and higher power usage.

“There’s a growing need for increased signal detection capability in industrial applications,” Hann said. “You need a a marriage of high precision and high sampling speed to improve the safety, reliability, and efficiency of the system.”

“If your system is responding to a sensor that has very low signal levels, for example, having higher precision and lower noise measurement capability will help detect these low-level signals so that a response can be performed early to keep the system safe and reliable,” he added.

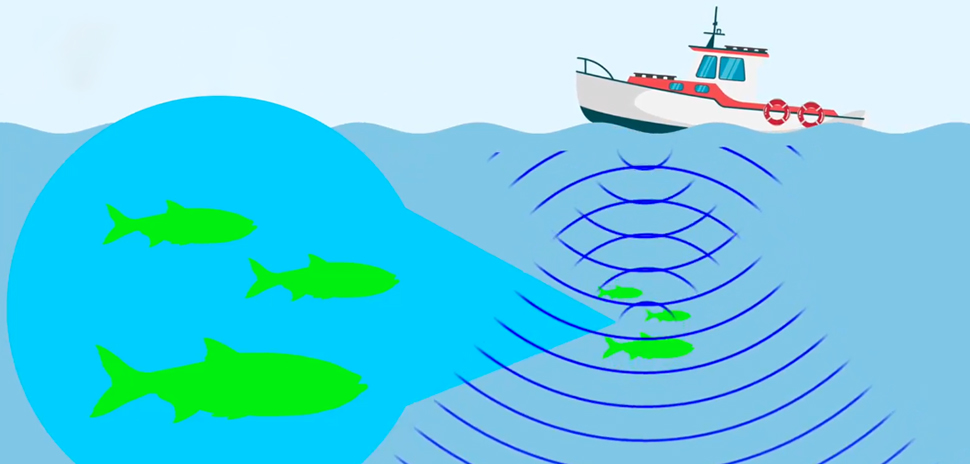

Target applications: From grids to fish

Thermal imaging cameras, plasma cutters, grid infrastructure systems, test and measurement equipment are all target applications for these ADCs, including many others—even catching a fish.

[Image: Video still/Texas Instruments]

Fishermen often use “fish finders,” sonar that pings off a fish. Using digital signal processing, the fish’s location and depth can be computed and visualized on a display. The sonar’s signal-to-noise ratio is what determines how accurately the reflected “pings” can be digitized. TI’s new ADC3660 family increases this accuracy with sample rates up to 125 megasamples per second and up to 18 bits of resolution, increasing object sensitivity and detection.

In other words, ADC3660 helps you find your fish better than ever before. And it can improve performance in a similar way across a wide array of industries and applications.

Target customers: design engineers

TI’s target customers are design engineers—electrical engineers at companies that design industrial equipment. The engineers can use them to design “high-speed digital control loops with the highest dynamic range and lowest latency while reducing power consumption by as much as 65%,” TI said in a statement.

The ADC3660 family includes eight SAR ADCs in 14-, 16-, and 18-bit resolution at sampling speeds ranging from 10 to 125 MSPS, helping designers improve signal resolution, extend battery life, and strengthen system protection.

In a high-speed digital control loop, the ADC acts in a complex system to respond to fast changes in voltage or current to help prevent costly damage to critical components in power-management systems, the statement said. As the number of data-intensive tasks in industrial systems increases, quick decisions by systems become even more important to prevent system failures. That requires higher precision at faster speeds, which the ADC3660 family addresses.

No need for performance ‘tradeoff’

Until now, design engineers had to choose between excellent noise performance and low power consumption—a decision that was especially tough for battery-operated devices that require precise data acquisition. The ADC3660 family eliminates this trade-off, TI says. For example, the ADC3683—the industry’s fastest 18-bit ADC at 65 MSPS—improves noise performance in narrowband-frequency devices like portable defense radios, delivering a signal-to-noise ratio of 84.2 dB while maintaining low power consumption of 94 mW per channel.

Reducing complexity and cost

The ADC3660 family’s high sampling speeds and integrated features help designers do something else important: reduce the number of components in their systems.

For example, the ADC3683—which samples four times faster than the closest competing 18-bit device at twice the channel density—enables oversampling, a technique that pushes harmonics further from the desired signal, the TI statement said. This allows designers to reduce antialiasing filter complexity and system component count by as much as 75%.

Design complexity can also be reduced thanks to on-chip decimation options that can help remove unwanted noise and harmonics in a system. These options and a complementary CMOS interface can also help lower costs, by enabling designers to use these ADCs with Arm-based processors or digital signal processors instead of field-programmable gate arrays, TI says.

Processor resources can be reduced, too, thanks to an integrated digital downconverter with a complex numerically controlled oscillator.

Want to dig even deeper? Check out this and this.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.

![TI's new radar sensor gives automotive engineers more tools that can fuel vehicle innovation. [Source image: Texas Instruments]](https://s24806.pcdn.co/wp-content/uploads/2022/01/TI-radar-sensor_courtesy-970x464.jpg)