Irving-based Darling Ingredients calls itself “the greenest company on the planet”—and just announced a new partnership with Chick-fil-A that could make the world even greener.

Darling Ingredients’ service brand DAR PRO Solutions will collect used cooking oil from all Chick-fil-A restaurants in the U.S. and Canada, for conversion into cleaner-burning renewable fuel.

The finished renewable fuel reduces greenhouse gas emissions up to 85 percent compared to traditional petroleum diesel, Darling says.

“We admire Chick-fil-A’s commitment to reducing food waste, and are proud to be part of a solution that keeps food waste out of our landfills while delivering a renewable fuel that reduces GHG emissions,” said Sandra Dudley, Darling’s EVP of Renewables and U.S. Specialty Operations, in a statement.

Darling Ingredients’ chairman and CEO, Randall Stuewe, says that no matter where people stand on climate change, the effort makes sense.

“If somebody had a drop-in solution that says ‘I can reduce the tailpipe emissions out of heavy transportation by 80% to 90% tomorrow,’ it seems like the right thing to do,” Stuewe says in his company’s recent Vision 2045 video.

Also recycles cooking oil from Wingstop, Wendy’s, and others

Wingstop COO Mahesh Sadarangani gives a tour to Darling chairman and CEO Randall Stuewe. [Video still: Darling Ingredients]

Darling casts a wide net in its efforts to recycle used cooking oil. It also partners with fast-food restaurant chains like Wendy’s and Dallas-based Wingstop, which owns over 1,500 restaurants globally.

“We started testing DAR PRO in our corporate locations in 2019 and saw overwhelming success,” said Mahesh Sadarangani, COO of Wingstop, in the Vision 2045 video, “Not only from a sustainability standpoint, but also from a team member safety standpoint.”

“In 2020, DAR PRO created three-quarters of a million gallons of renewable diesel fuel from Wingstop locations,” Sadarangani added. “The savings in greenhouse gases from this process equates to more than 1,400 cars off the road for one year.”

And last spring, Wendy’s Corporate Responsibility Report cited its partnership with DAR PRO for producing 2.8 million gallons of cleaner-burning renewable diesel from 24 million pounds of used cooking oil in the U.S.

In all, Darling takes in used cooking oil from 100,000 customers worldwide, according to Suann Guthrie, Darling’s VP of investor relations, sustainability and global communications.

“Because used cooking oil cannot be poured down the drain, the food industry needs a solution and equipment to handle their waste responsibly and in accordance with governmental and environmental regulations,” Guthrie told Dallas Innovates. “Darling Ingredients provides a way to streamline their waste operations and support their sustainability goals by offering a turn-key solution for the pick up and recycling of used cooking oil.”

Partnering with Valero to be world’s largest renewable diesel supplier

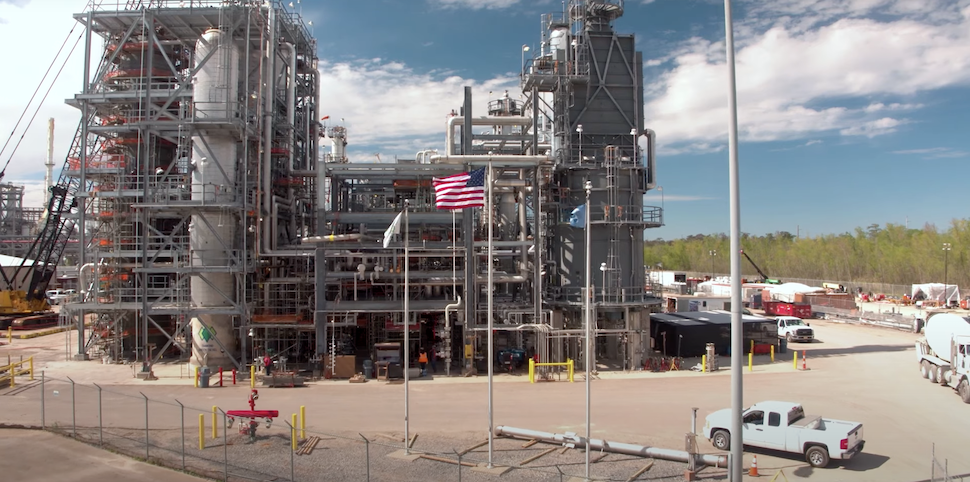

Diamond Green Energy facility. [Video still: Darling Ingredients]

Each year, Darling Ingredients turns “hundreds of millions of pounds” of used cooking oil into renewable diesel via Diamond Green Diesel, its 50/50 venture with San Antonio-based Valero Energy. DGD estimates it will produce around 750 million gallons of renewable diesel this year alone.

“I see Darling playing a significant role going forward around the world,” Darling’s chairman and CEO, Randall Stuewe, says in the video. “We’ve chartered a five-year plan here to grow Darling into the largest renewable diesel supplier with our partner Valero in the world today—converting waste fats and greases to the most low-carbon-intensity fuel in the world today that’s readily available and affordable.”

Diamond Green Diesel began production in 2013 as a 50/50 venture between Darling and Valero. Last November, the companies completed a major expansion of DGD’s facility in Norco, Louisiana, which increased production from 290 million gallons to 690 million gallons, according to Darling.

And more capacity is coming.

“We’re well on the way to completing our third expansion, a facility in Port Arthur, Texas,” Guthrie said. “When complete in early 2023, we’ll have the capacity to make 1.2 billion gallons of renewable diesel annually.”

$1.1 billion cash acquisition of Valley Proteins

A recent big acquisition could help Darling in its renewable fuel recycling efforts. In late December, Darling announced it would pay $1.1 billion in cash for Winchester, Virginia-based Valley Proteins, a waste collection and recycling startup. The deal remains to be completed pending the government approval process, but would include Valley Proteins’ 18 major rendering and used cooking oil plants.

Beyond biodiesel to a wide array of sustainable global solutions

Biodiesel production is just one of many solutions Darling Ingredients pursues to create a more sustainable planet. From “neutraceuticals”—collagen-based solutions for consumers’ health and beauty—to sports nutrition products and biomedical applications for purified gelatins and collagens.

With 10,000 global employees—including 300 in the Dallas area—the company operates 250 plants in 17 countries and repurposes nearly 10% of the world’s meat industry waste streams into products including green energy, renewable diesel, collagen, fertilizer, animal proteins, and meals and pet food ingredients.

“Darling is the largest repurposer/recycler of waste streams from the food production system in the world today,” Stuewe explains in the video. “It focuses primarily on the animal byproduct side, but it is also is one of the largest if not the largest bakery recycler, and it’s the largest used cooking oil recycler in the world today. And out of those wastes streams, it converts them into products for food, for feed, for pet food, and for green fuels.”

Innovating pet food with insects

EnviroFlight President Lliz Koutsos, Ph.D. [Video still: Darling Ingredients]

In one of Darling’s most intriguing endeavors, in January 2020 it acquired 100% of EnviroFlight LLC, a leader in sustainable animal and plant nutrition “aiming to drive transformative change in the global food supply.”

Talk about change—EnviroFlight aims to do that by rearing and processing black soldier fly larvae into high-value nutrients.

“We can grow 1,000 times the protein with an insect production facility as we can with chickens or pigs or cows,” says Liz Koutsos, Ph.D., president of EnviroFlight, in Darling’s Vision 2045 video.

“The insect protein industry is a growing industry,” she adds. “People understand there’s a need to grow more protein to feed the growing population of humans in the world. And so there’s tremendous interest in growing insects to either feed animals to feed humans, or to feed humans directly.”

EnviroFlight uses waste from groceries, distillers, brewers, restaurants, and bakeries to grow their non-pathogenic black soldier fly larvae, diverting the waste from places like landfills.

“It’s very exciting to be part of the only company in the U.S. right now raising black soldier fly larvae at a commercial scale,” Koutsos says. “The next markets we’re working for are pet food, and the regulatory profits are well underway. The pet food industry is very excited to use insect proteins as a novel protein source, particularly for animals that have allergy issues.”

“Not only are we developing these technologies, we are the first to do it in the U.S., and we’ll be leading the industry,” she says.

If you think feeding animals insects sounds strange, think again. Virtually all animals eat insects in some capacity in their native environment, EnviroFlight says—and within the fish and poultry markets, BSF larvae may better represent their typical diet than soybean meal and other plant-based proteins, which they are now typically fed.

Originally founded in 1882: ‘Green before green was cool’

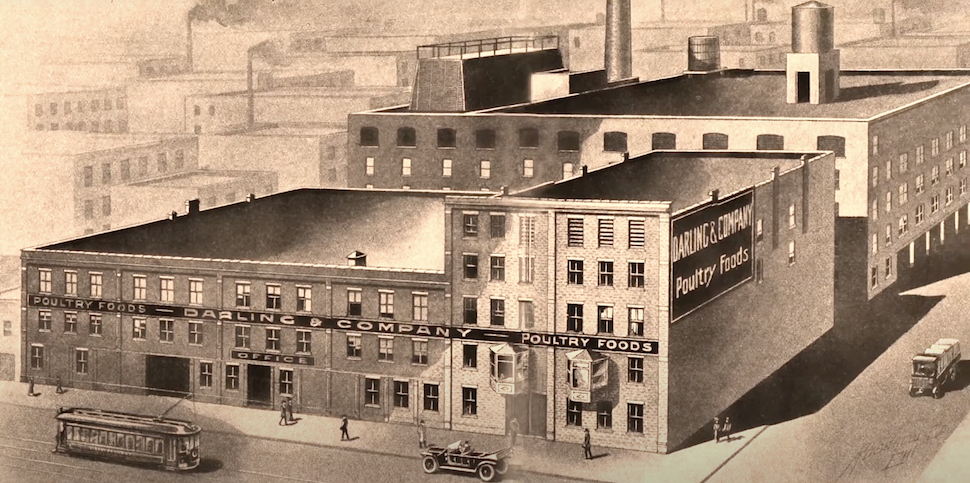

Darling Ingredients’ history dates back to 1882 in Chicago. [Video still: Darling Ingredients]

Darling’s history goes way back to 1882, when the Ira C. Darling company was formed in Chicago. It evolved from a small rendering company into the world’s leading developer and producer of sustainable organic ingredients.

A Texas investor group purchased the company in 1986 and moved its headquarters from Chicago to the Dallas area. It’s continued to innovate since through acquisitions,

“When I look at Darling, I say we are the greenest company on the earth,” Randall Stuewe, who’s held the company’s chairman and CEO posts since 2003, says in the video. “There’s no one that does what we do, and has more fun at it, and is better at it around the world.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.