We’re racing toward an electrified future—ditching gas-guzzlers for EVs, storing energy from solar panels, and adding constant new stockpiles of electronic devices. That will require countless millions of new batteries. One way to produce them? Recyling lithium-ion batteries and rare earth permanent magnets—which is exactly the mission of Dallas-based Momentum Technologies.

Today, Momentum landed a $20 million investment from Freestone HoldCo LLC, a portfolio company of Dallas-based Tailwater Capital.

The funding will help Momentum build its first two battery recycling plants and build out additional commercial recycling facilities in the future. The two plants are expected to be fully operational by end of 2022.

Licensed process from Oak Ridge National Laboratory

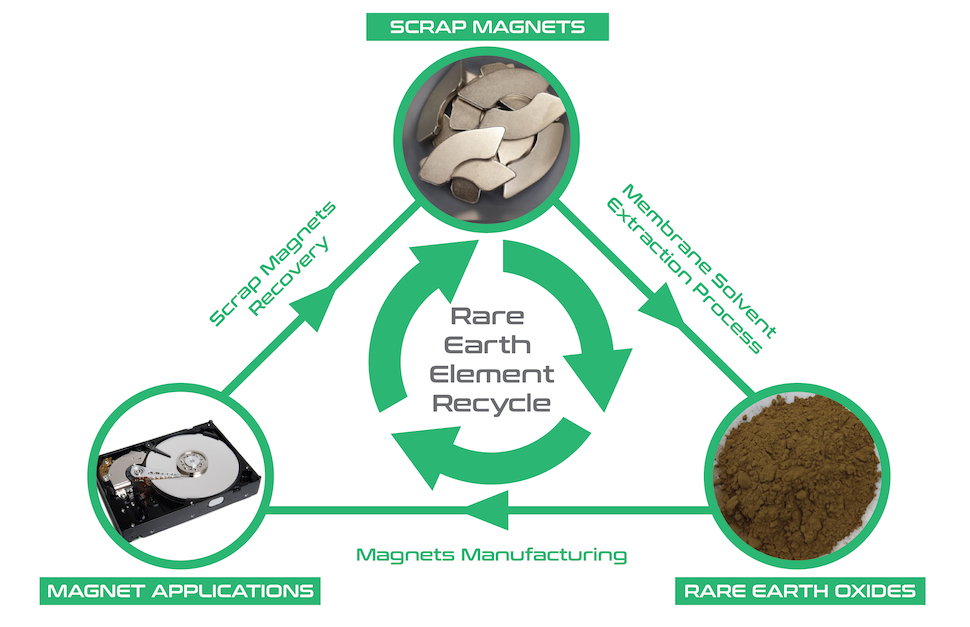

Founded in 2016, Momentum installs and operates recycling plants for its customers using its patented recycling technology, membrane solvent extraction (MSX).

MSX was developed by the U.S. Department of Energy’s Critical Materials Institute at Oak Ridge National Laboratory. The process extracts high-purity metals from recycled cell phones, hard drives, and other battery waste at industry-leading operating and capital costs.

The patented MSX process recovers more than 97% of the rare earth elements from scrapped magnets at purities exceeding 99.5% by weight. The recovered material can be made into new magnets for electronics and other applications. [Image courtesy of Oak Ridge National Laboratory, U.S. Dept. of Energy. Created by Syed Islam and Jason Smith.]

Momentum has an exclusive license for the technology, which is able to yield rare earth oxides at purities exceeding 99.5%.

The process helps the environment by reducing total electronic waste. It allows Momentum to install recycling capacity tailored to customer demand and to build recycling plants close to its customers, reducing transportation-related costs and emissions.

Researchers at Oak Ridge are now working with Momentum to scale the process further to produce commercial batches of rare earth oxides.

Preston Bryant, founder and CEO of Momentum Technologies. [Photo: LinkedIn]

Momentum CEO is on the Forbes 30 Under 30 list

Momentum’s founder and CEO, Preston Bryant, was named to the Forbes 30 Under 30 list for 2021.

“Over the last several years, we’ve worked with Oak Ridge to perfect the MSX process, and we’re now ready to deploy it at a commercial scale,” Bryant said in a statement.

Freestone’s “significant experience in the recycling and energy infrastructure verticals will serve as a great resource for the company and will position us for long-term success,” Bryant added. “This partnership will provide valuable financial and operational support as we enter an important new chapter of growth.”

U.S. economy is vulnerable to sources of critical materials

Last February, President Joe Biden ordered a 100-day review of America’s supply chains to find more resilient, diverse, and secure sources for a wide range of things including critical minerals.

A 2020 Department of Energy report had already pointed out how vulnerable the U.S. economy is to critical materials sources. For instance, the report said that 60% of the world’s cobalt is mined in the Democratic Republic of the Congo, with 80% of that supply being processed in China.

Phys.org published an article last spring noting that companies are looking at new ways of recycling to supply the critical minerals needed for EV batteries. Momentum is one of the companies that’s getting around the sources problem by recycling spent lithium ion batteries to reclaim their critical minerals.

Innovations are essential for battery supply chain

John Schaufele, president of Freestone, believes Momentum will be a key player in battery metals innovation moving forward.

“Sourcing sufficient critical metals to support the expected exponential growth in battery deployment in electric vehicles, handhelds, and stationary power storage will require continued technological innovations in the battery supply chain,” Schaufele said in the statement. “Momentum provides a cost-competitive and environmentally friendly battery recycling solution for its customers. We’re excited to fund Momentum as the company commercializes its technology and supports the continued evolution of the battery metals industry.”

Named to Halliburton Labs’ clean tech accelerator program

Last February, Momentum was one of first three companies named to Halliburton Labs’ clean tech accelerator program. The Halliburton Company has continued to be a strategic partner in Momentum’s plant design and commercialization efforts.

Tailwater: Momentum’s MSX process is ‘sustainable, environmentally friendly’

Tailwater Capital partner David Cecere sees Momentum as checking off critically important boxes.

“We understand the importance of investing across the entire energy opportunity set, and Momentum provides an attractive growth infrastructure investment in two of our core areas of expertise—feedstock processing and material recycling,” Cecere said.

“The exponential growth in electric vehicles will require innovative solutions in order to alleviate battery supply chain constraints while also addressing these issues in a more sustainable and environmentally friendly way,” he added. “Momentum’s MSX process checks both of these boxes and we’re excited to enter into this partnership.”

The Freestone partnership is just one example of Tailwater’s commitment to supporting companies moving the world toward a low-carbon economy. It’s also invested in Frontier Carbon Solutions, a carbon sequestration service provider, and Blue Tide Environmental, a recycler and developer of finished lubricants through liquid waste upgrade technology.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.