A grant earned by a researcher at UT Arlington for state-of-the-art hybrid additive-subtractive manufacturing equipment could have implications for working deep in the sea or even the harsh conditions on Mars.

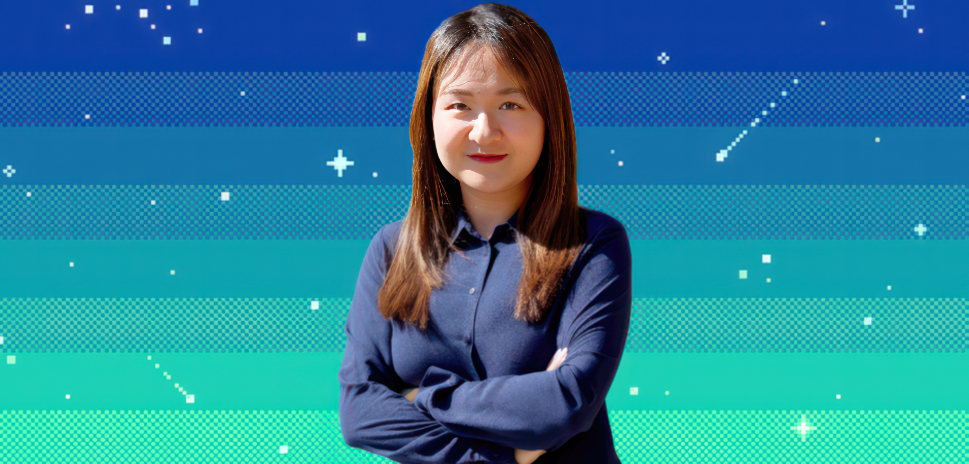

Emma Yang, an industrial engineering researcher at UT Arlington, received the grant from the Department of Defense to purchase the equipment. The grant’s amount was not disclosed.

“This equipment will help us determine how the Navy could use hybrid manufacturing to effectively and efficiently repair and remanufacture parts,” Yang said. “With this machine, if you have a defective part or one that is worn from use, you can just fix the part instead of having to replace it. The Navy could use this on a ship at sea, and if you combine zero-gravity printing, you could eventually print parts where resources and tools are very limited, like on Mars.”

Solving problems on the fly

The university said that the project will improve manufacturing capabilities at UTA for printing a wide range of metals and alloys. Yang is an assistant professor in the Industrial, Manufacturing, and Systems Engineering Department and is an expert in additive and sustainable manufacturing.

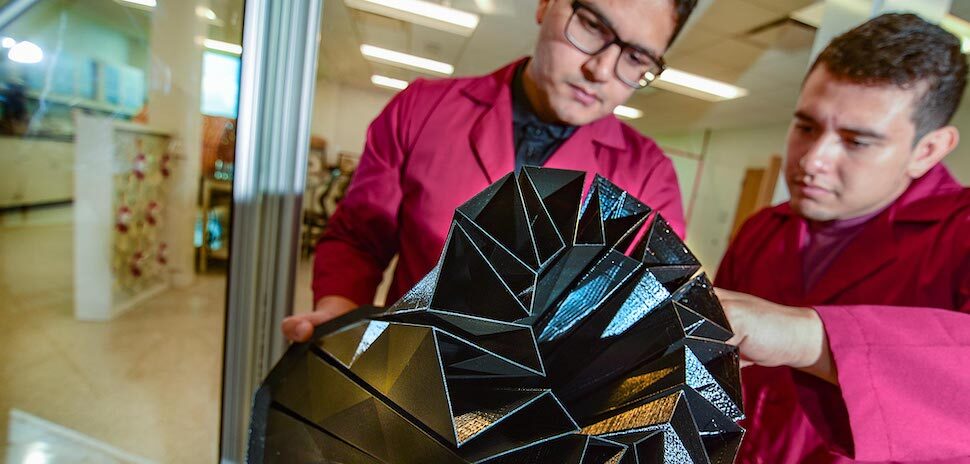

UTA said that the hybrid machine has a multimodal in-situ monitoring system that includes a high-speed camera, infrared temperature sensor, melt pool monitor, and ultrasound inspection.

The machine will allow Yang and her team to identify fabrication anomalies during the printing process so they can be corrected immediately, rather than finding the problem after the print is complete, UTA said.

The university called the equipment critical to the education of the next generation of scientists and engineers. It added that Yang plans to develop a bilingual English/Spanish virtual training platform for hybrid manufacturing that integrates knowledge and research findings generated from the machine.

Funding for minority-serving institutions

Funding for the project is from Historically Black Colleges and Universities/Minority-Serving Institution grants provided by the Department of Defense to fund programs that will improve the capabilities of those institutions to conduct research and educate scientists and engineers in areas important to national defense, the university said.

UTA said it earned the Hispanic-Serving Institution designation in 2014.

More than 570 universities are designated as Hispanic-Serving Institutions by the U.S. Department of Education.

Among them, UTA is No. 3 for awarding bachelor’s degrees to African American students, No. 12 for Asian American students, No. 15 for Hispanic students, No. 10 for Native American students, and No. 8 for total minority students, according to the magazine Diverse: Issues in Higher Education.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.