Toyota’s expanding line of battery-powered cars and trucks will get some juice from LG Energy Solution.

Toyota Motor North America announced it has signed a long-term deal for LG Energy Solution to supply lithium-ion batteries for Toyota’s growing portfolio of battery electric vehicles (BEVs) in North America.

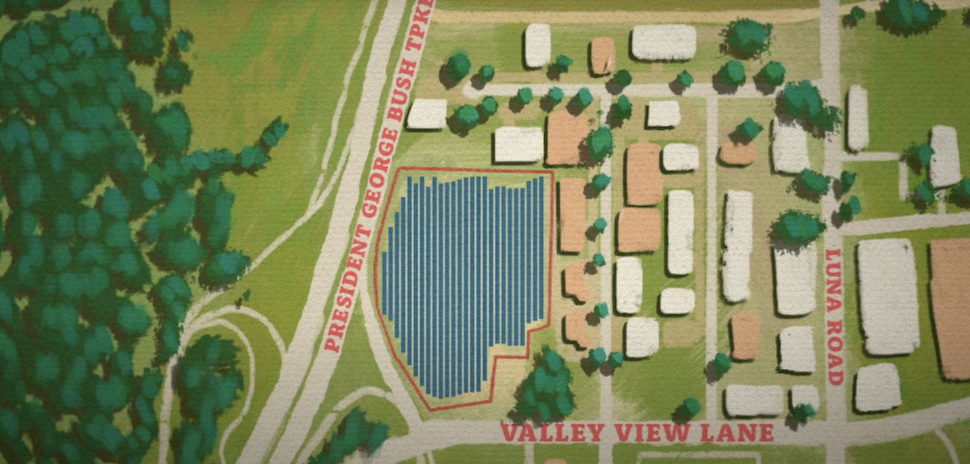

Under the agreement, LG Energy Solution will provide 20 gigawatt-hours of battery modules annually starting in 2025. The batteries—produced at an LG Energy Solution facility in Holland, Michigan— battery modules will power Toyota BEVs assembled in North America, including an all-new model expected to roll off the lines at Toyota’s Kentucky manufacturing plant.

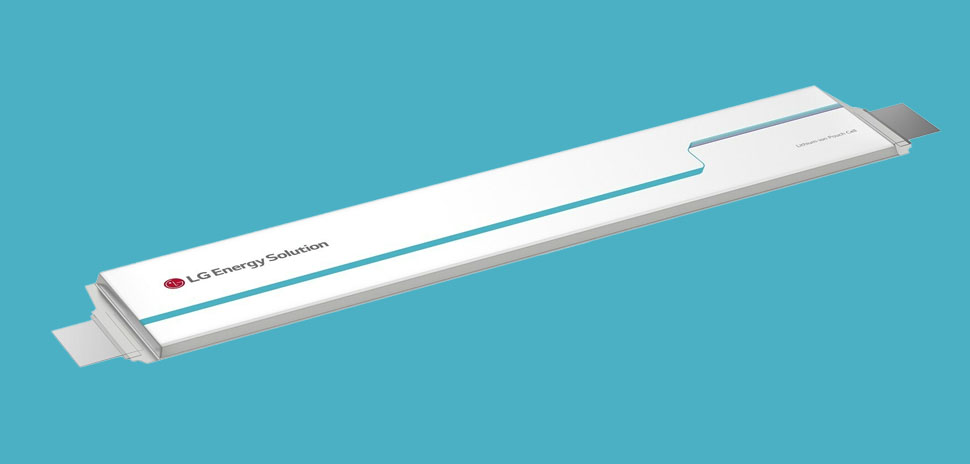

The partnership combines LG Energy Solution’s large-scale manufacturing of high-quality battery cells and modules—including high-nickel NCMA (nickel, cobalt, manganese, aluminum) pouch-type cells—with Toyota’s advanced technologies for battery packs.

Optimized performance and safety

Together, the industry giants aim to create batteries with optimized performance, safety, and thermal management using LG Energy Solution’s “innovative power solution.” The optimized batteries can provide peace of mind for BEV customers and enhance the electric driving experience, the companies said.

In the announcement, Ted Ogawa, Toyota North America’s CEO, said the long-term relationship with LG Energy Solution supports the company’s growth plans for BEVs in North America.

Toyota aims to offer 30 fully electric models globally across its Toyota and Lexus brands and sell 3.5 million all-electric vehicles annually by 2030.

$4 billion in new production lines

“We’re excited to have Toyota, the best-selling global automaker, as our new customer,” Youngsoo Kwon, CEO of LG Energy Solution, said in a statement.

Kwon called the agreement “another big opportunity” for LG Energy Solution to bring more “real-life, large-scale progress toward electrification” to North America.

The deal represents LG Energy Solution’s largest single supply contract outside of a joint venture, according to the news release. The agreement cements LG Energy Solution’s status as a battery provider to all top five global automakers, including General Motors, Stellantis, Hyundai, and Honda.

LG Energy Solution’s commitment is backed by a significant investment. LG Energy is spending about $4 billion to add new production lines for battery cells and modules exclusively for Toyota for 2025 completion, the companies said.

LG Energy Solution, which started as a split-off from South Korea’s LG Chem, has grown into a leading global manufacturer of lithium-ion batteries for electric vehicles, consumer electronics, and energy storage. With an extensive R&D operation and three decades of experience, LG Energy holds over 25,000 patents, claiming its place as the “top battery-related patent holder in the world.”

Carbon reduction plans

“At Toyota, our goal is to reduce carbon emissions as much as possible, as fast as possible,” Toyota CEO Ogawa said.

With over two dozen hybrid and plug-in options, Toyota says it sells more electrified vehicles in the U.S. than any other automaker. The company is pushing to electrify even more of its lineup to reduce emissions and meet stringent government fuel economy standards.

The company has its 14th Toyota plant currently under construction in North Carolina, which will start producing automotive batteries in 2025 to power electrified models.

Ogawa says securing supplies of lithium-ion batteries at scale is critical to achieving Toyota’s manufacturing and carbon reduction plans.

“Working with LG Energy Solution, we are excited to be able to offer products that will provide the performance and quality our customers expect,” he said.

LG Energy Solution aims to achieve carbon-neutral manufacturing by 2050.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.