Cleburne-based next-generation indoor vertical farming company Eden Green Technology has launched its flagship herb program—making it the first company to grow, package, and ship a full herb suite out of a single facility, the company said.

Eden Green said the program leverages its patented microclimate technology and networked distribution model to improve logistics, reduce environmental impact, and increase access to fresh, affordable herbs.

“Until now, the agricultural industry relied upon aggregators piecing together different herb crops from around the world to deliver fresh, affordable, and high-quality produce year-round. Innovative approaches are necessary to keep up with growing demand, particularly with complex programs like herbs,” Eden Green CEO Eddy Badrina said in a statement. “Our grow system is the only solution capable of supplying an entire herb program out of a single facility. We believe this process is the key to delivering fresh, high-quality produce sustainably and at an affordable price.”

Eddy Badrina, CEO of Eden Green Technology [Video still: Harvest Green]

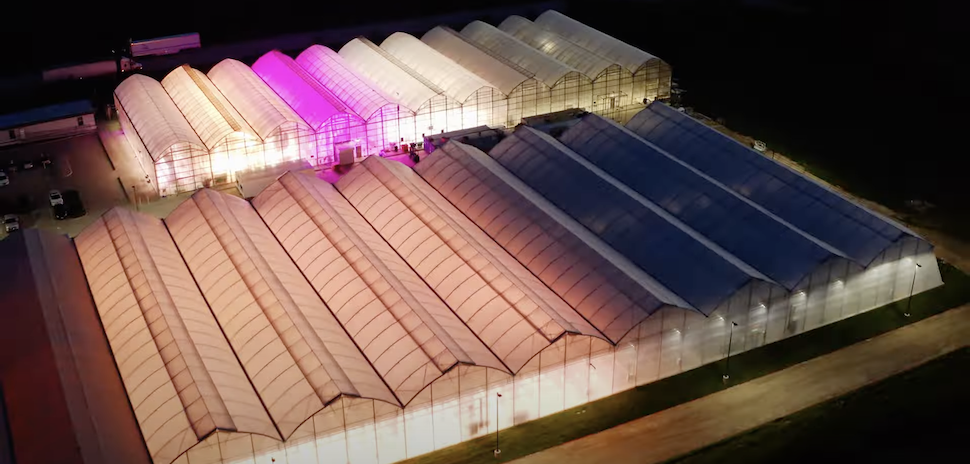

The move comes five months after Eden Green broke ground on its $40 million Phase 2 expansion of its Cleburne campus and announced that Will Parkey had joined the company as chief financial officer. At the time, Eden Green said the expansion was aimed at scaling commercial production to meet rising market demand.

The challenges of getting herbs from farms to markets

Eden Green said that cultivating a diverse array of herbs presents a significant challenge for a traditional farm or greenhouse because each variety requires specific climatic conditions and matures at a different rate. The company said its innovative microclimate technology addresses that challenge by enabling each plant to grow in a customized environment and receive a meticulously calibrated nutrient mix all year long.

Such an advanced approach optimizes the use of energy, water, and nutrients and allows various herbs to thrive side by side in a single facility, instead of in separate farms located in different climates across the country, Eden Green said.

The result is a less wasteful, more efficient, and cost-effective method to grow a diverse selection of herbs, enhancing the potential for faster and more sustainable cultivation, the company said.

Along with resource efficiency, the company said its herb program will dramatically simplify supply chain logistics. In the typical retail model, for example, sourcing a complete suite of herbs necessitates multiple distributors and international importation. That’s logistically complex, and herbs spend most of their shelf-life in transportation, undergoing repeated packaging.

How Eden Green speeds the trip

Eden Green said it has revolutionized that process by growing and packaging all major herb varieties in a single vertical greenhouse.

Strategically located within miles of major distribution centers, Eden Green said it can now deliver herbs from farm to shelf within 48 hours. That, combined with innovative packaging solutions that reduce waste and time spent repacking products, drastically reduces the distance food travels, ensures unparalleled freshness and nutrition, and streamlines logistics for retailers, the company said.

Eden Green said it will grow more than 10 herb varieties, including basil, cilantro, chives, dill, mint, oregano, parsley, rosemary, sage and thyme and one facility alone can produce 350,000 to 400,000 pounds of fresh, sustainable herbs a year.

The company will distribute herbs to some of the largest retailers and food service companies in the U.S. through its exclusive distributor, Robinson Fresh, a provider of fresh produce and supply chain services.

“To supply a variety of fresh, high-quality produce to people around the world, sustainably and affordably, we need truly disruptive technologies,” Molly Tabron, director of supply at Robinson Fresh, said in a statement. “Eden Green’s unique approach to fresh produce does just that, and we look forward to seeing the herb program come to life.”

‘The perfect partner’ and a patented process

Badrina said that Robinson Fresh has been an ideal partner for Eden Green.

“Their logistic expertise, and their deep relationships with retail and food service providers, have been essential to our growth and continued success,” Badrina said.

Eden Green said it is the only greenhouse grower and packer able to grow 10 herbs in a singular facility.

It creates microclimates for each plant, an individualized, highly customizable environment localized to a specific plant, whose roots receive a precise nutrient mix every 90 seconds through a temperature controlled and filtered closed loop water system.

Responsive air control for oxygen and carbon dioxide allows temperature and humidity within the microclimate to be adjusted in seconds, the company said.

Eden Green said that by focusing on individual plants, Eden Green’s patented process allows for:

- Multi-Crop Cultivation: Because the microclimates act as a personalized incubator for each plant, Eden Green can grow up to 200+ products in one vertical farm.

- Greater Efficiency & Zero Waste: Rather than conditioning a full greenhouse, Eden Green manages only the climate around each individual plant which enables precise control over resources being utilized, saving energy, water and nutrients.

- Faster, Higher-Quality Harvests: Plants receive individualized nutrients and environmental conditions, resulting in faster and higher quality harvests.

Eden Green Technology is a privately held company with a mission to provide hyperfresh and locally-grown produce for all.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.