“One word: plastics.” That’s the famous career advice from the movie The Graduate. A professor at UT Arlington must have gotten the same message, because 56 years later he’s making history by using plastics to repair and stabilize Texas roadways in the DFW area.

Dr. Sahadat Hossain—a UTA civil engineering professor and director of the school’s Solid Waste Institute for Sustainability—got a grant of around $950,000 from the Dallas district of the Texas Department of Transportation to achieve the first use of “plastic road” material in Texas.

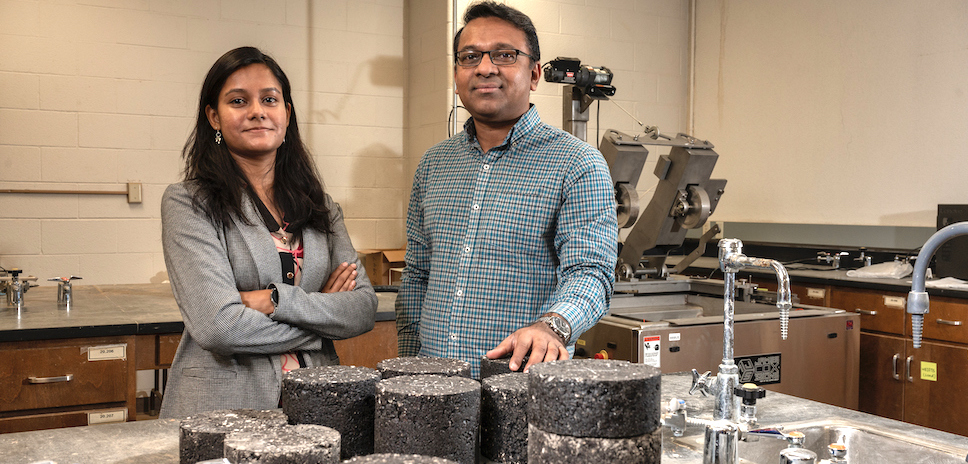

Working with co-principal investigator Karthikeyan Loganathan, an assistant professor of civil engineering at UTA, Hossain is using both “recycled and unrecycled plastic waste products” to fill in surface cracks and reduce rutting in roads.

The first plastic road implementation project will be in the area of Kaufman, a suburb southeast of Dallas, UTA says.

Lab investigation has taken three years

Assistant Professor of Civil Engineering Warda Ashraf with Dr. Hossain in the Nedderman Lab at UTA, with examples of the asphalt/recycled plastic road material. [Photo: UTA]

Over the last three years, Hossain and his team performed a lab investigation that led to the successful reuse of waste plastics in asphalt.

Their research shows that plastics can improve the durability and strength of highway pavement, as well as serve as a replacement for bitumen in asphalt pavement roads.

Hossain met with the World Bank about his projects’ ‘green’ potential

According to UTA, Hossain recently met with the World Bank to discuss implementation of plastic road projects in developing countries.

“This is a perfect example of reuse of recycled materials for circular economy and green economy,” Hossain said in a statement.

But this project is just one of three that Hossain is currently pursuing, including a moisture barrier project in Fort Worth and a slope stabilization approach for highways.

DFW moisture barrier project for TxDOT

[Photo copyright carloscastilla via iStock]

In a second project, the Fort Worth district of TxDOT awarded Hossain $637,060 to implement “moisture barriers that reduce cracks and improve durability and strength of highway pavement and shoulders.” His modified moisture barriers will be put to work in five locations in the Fort Worth district and two locations in the Dallas district.

“This new method could save TxDOT even more on pavement maintenance cost,” Hossain said.

Ricardo Gonzalez, director of TxDOT Fort Worth, sees promise in working with UTA and Hossain in the future as well.

“The technology proposed and the benefits discussed have a potential of cost savings to the department,” Gonzalez said in the statement. “Due to the results described on rutting of the pavement, this would be beneficial to address a concern of rutting pavement within our system with a potential increased durability.”

Third project has used 8- to 10-foot “pins” to stabilize highway slopes

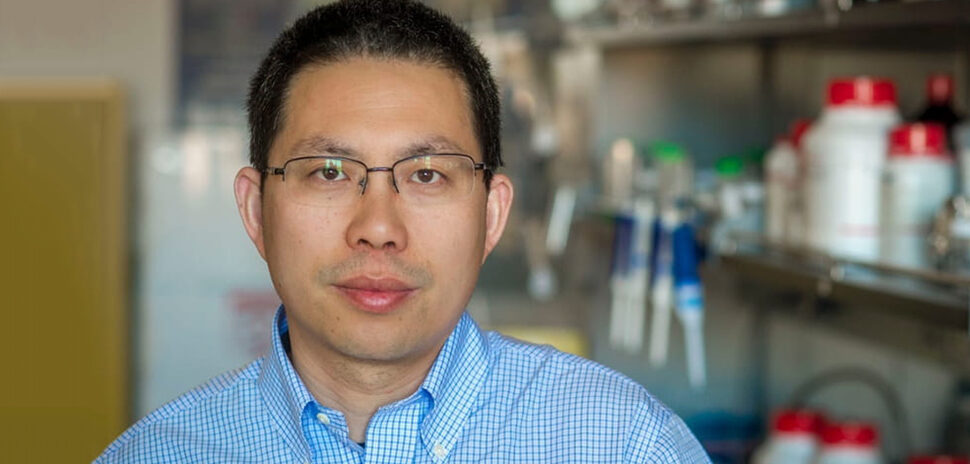

UT Arlington Civil Engineering Professor Sahadat Hossain. [Photo: UTA]

In a third project led by Hossain, large recycled plastic “pins” have been used to stabilize highway soil slopes. The pins—which range in length from 8 to 10 feet —are driven into the soil to stabilize the slope.

“This is a very cost-effective and green solution compared to existing slope stabilization methods,” Hossain said.

As far back as 2013, Hossain’s team used the pins to shore up slopes on U.S. 287, State Highway 183, and I-35, as Dallas Innovates previously reported.

Other states have taken notice

Melanie Sattler, interim chair of UTA’s Department of Civil Engineering, said other states have taken notice of Hossain’s approach. They’re now adopting recycled plastic pins as well, to shore up their own unstable highway embankments.

“Dr. Hossain is a leader in the field,” Sattler said. “His innovative use of recycled plastic is making infrastructure construction more sustainable.”

Described by UTA as “a global leader in sustainable waste management,” Hossain is currently conducting other research projects as well. They include new approaches for landfill recycling and how to make landfills more sustainable, the university said.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.