Aurora Innovation—which aims to begin rolling totally human-free trucks between Dallas and Houston by late 2024—announced that it has reached a key development milestone to commercialize autonomous trucks at scale.

In partnership with Continental—which is based in Germany with a U.S. HQ in Auburn Hills, Michigan—Aurora says the two companies have finalized the design and architecture of the future fallback system and hardware of the Aurora Driver—an SAE Level 4 autonomous driving system—that Continental plans to start production of in 2027.

The finalized hardware design comes less than a year after the companies entered an “industry-first partnership” aimed at high-volume manufacturing of autonomous trucking systems.

Aurora said the partnership gives it a path to deploy autonomous trucks at scale after its initial driverless launch, planned at the end of 2024. Aurora says it teamed up with Continental to jointly develop “reliable, serviceable, cost-efficient autonomous hardware kits for mass production.”

In November, the Pittsburgh-based company announced it had opened the industry’s first lane for driverless trucks supported by commercial-ready terminals in both Dallas and Houston.

Million-mile operational goal

Photo: Aurora

The future Aurora Driver will be designed to deliver customer value “for one million miles,” the company said.

“Technologies for autonomous mobility present the biggest opportunity to transform driving behavior since the creation of the automobile,” Philipp von Hirschheydt, executive board member for the Automotive Group sector at Continental, said in a statement. “Achieving this milestone puts us on a credible path to deploy easy-to-service autonomous trucking systems that customers demand.”

Fallback system is a key ‘redundancy’ for the Aurora Driver

Inside a Continental facility [Video still: Aurora Innovation]

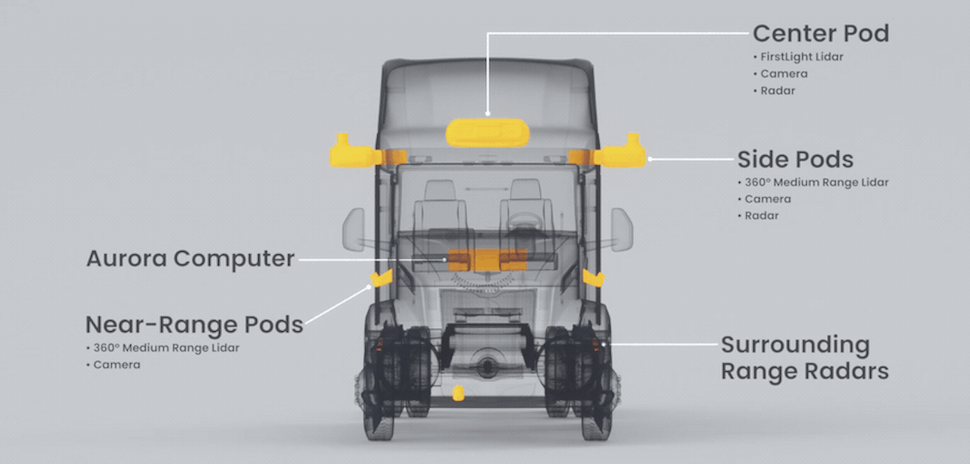

To operate safely without a human driver, autonomous vehicles require “built-in redundancies” that provide backups in the rare case a component or sensor fails, Aurora said. One of these redundancies is the fallback system—a specialized secondary computer that can take over operation if a failure occurs in the primary system.

Aurora says this dual engineering approach is intended to reduce the exposure of the main and fallback system to “single points of failure.”

“From day one, we knew we’d need to build a strong ecosystem of partners to bring this technology to market safely and at a commercial scale,” Chris Urmson, co-founder and CEO at Aurora, said in a statement. “Finalizing the design of our future hardware is a meaningful step toward making the unit economics of the Aurora Driver compelling and building a business for the long-term.”

Continental plans to build initial versions of the hardware for testing at its new facility in New Braunfels, Texas, and across its global manufacturing footprint in 2024 and 2025.

Between 2026 and 2027, Continental aims to “industrialize and validate” the future Aurora Driver hardware and fallback system before the start of production at its facilities. The hardware will leverage a wide spectrum of Continental’s automotive product portfolio from sensors, automated driving control units, high-performance computers, telematics units, and more, Aurora said.

The hardware and fallback system will be shipped to Aurora’s trucking manufacturing partners for integration into autonomous-ready vehicles. During this phase, the companies will also develop a service playbook and maintenance network for Aurora’s customers, the company added.

“Entering an exclusive partnership with Aurora was a very good decision as it is an ideal match,” von Hirschheydt said. “Being the industry’s only tier-one supplier with a commitment to industrialize autonomous hardware kits at scale allows us to be at the forefront of and capitalize on this groundbreaking technology.”

Continental will be showcasing its latest technologies—including its work with Aurora—at the annual CES trade show in Las Vegas this week.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.