Dallas-based semiconductor giant Texas Instruments has introduced six new power modules designed to improve power density, enhance efficiency, and reduce electromagnetic interference.

“Designers turn to power modules to save on time, complexity, size and component count, but these benefits have required a compromise on performance—until now,” Jeff Morroni, director of power management research and development at TI’s Kilby Labs, said in a statement. “After nearly a decade in the making, TI’s integrated magnetic packaging technology enables power designers to meet the defining power trend that has shaped our industry—pushing more power in smaller spaces efficiently and cost-effectively.”

TI said the new power modules have been nearly a decade in the making.

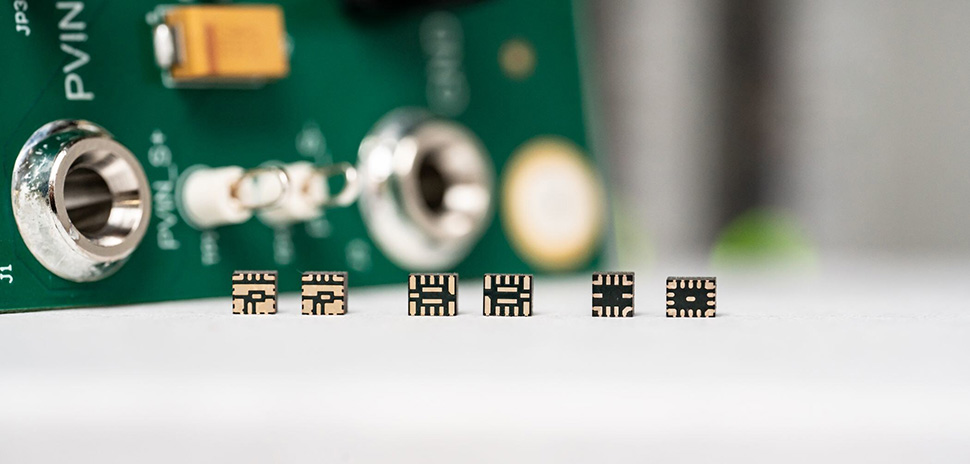

The new power modules leverage TI’s proprietary MagPack integrated magnetic packaging technology, shrinking their size by up to 23% compared to competing modules, enabling designers of industrial, enterprise and communications applications to achieve previously impossible performance levels.

TI said that three of the six new devices, the TPSM82866A, TPSM82866C and TPSM82816, are the industry’s smallest 6A power modules, supplying an industry-leading power density of nearly 1A per 1mm² of area.

Benefits of TI’s MagPack tech

According to TI, new power modules with MagPack technology are up to 50% smaller than previous generations, doubling power density while maintaining excellent thermal performance.

Power modules simplify power designs and save valuable board space by combining a power chip with a transformer or inductor in one package, the company said. By leveraging a unique 3D package molding process, MagPack packaging technology maximizes the height, width, and depth of the power modules to push more power in a smaller space, TI said.

Uses proprietary, newly engineered material

TI said its magnetic packaging technology includes an integrated power inductor with proprietary, newly engineered material.

Because of that, engineers now can achieve best-in-class power density and reduce temperature and radiated emissions while minimizing both board space and system power losses, the company said.

That’s especially important in applications such as data centers, where electricity is the biggest cost factor, with some analysts predicting a 100% increase in demand for power by the end of the decade.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.