The University of Texas at Arlington’s new arc-heated, hypersonic wind tunnel—the only one of its kind at a U.S. university—is ready to go to work aiding scientists in the study of heat shields for hypersonic vehicles.

The wind tunnel successfully underwent testing last month, marking a monumental moment in UTA’s long history of aerodynamics innovation and discovery.

Now, the wind tunnel will be used immediately for research funded by $1.5 million in grants from the Office of Naval Research. The grants are intended to develop advanced laser-based measurements of plasma flow in the study of heat shields for hypersonic vehicles, UTA said.

“This facility will enable pioneering research to be conducted in support of national priorities in hypersonics and plasma flows stretching the boundaries of knowledge in the fields of aerodynamics and materials,” UTA President Vistasp Karbhari said in a statement

Hypersonic is “supersonic on steroids,” as described by Popular Mechanics. Supersonic means faster than the speed of sound—Mach 1 is 767.269 miles per hour—and, generally speaking, hypersonic speeds are those at which molecules around an aircraft start to pick up electrical charges or by break apart.

Hypersonic speed is roughly Mach 5, or more than 3,500 miles per hour. Hypersonic vehicles that are cruising through the atmosphere at that speed or faster can encounter friction that heats them to more than 8,000 degrees Kelvin, or about 15,000 degrees Fahrenheit. As superheated air, or plasma, flows around the craft at those temperatures, it evolves. UTA said this requires engineers to simultaneously calculate the chemistry and fluid dynamics so it can develop an effective heat shield.

But currently, accurate predictions aren’t yet feasible.

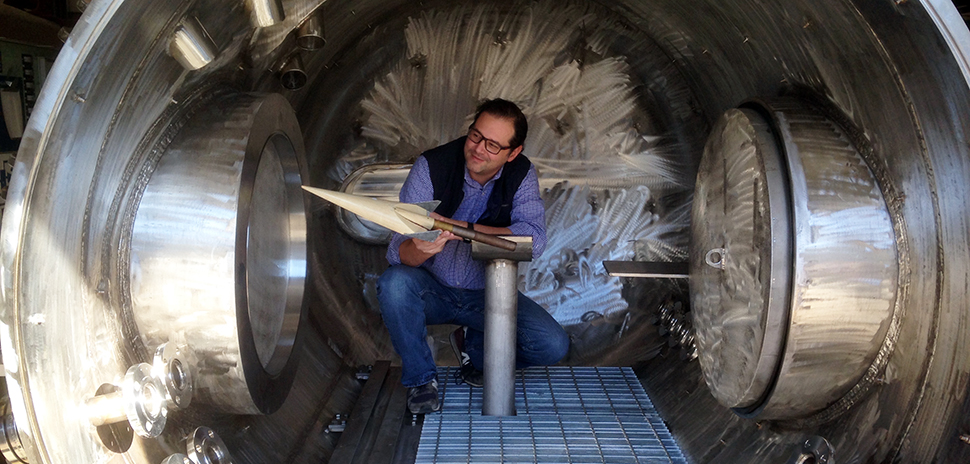

Luca Maddalena, a UTA aerospace engineering associate professor and the director of the Aerodynamics Research Center, and his team plan to develop diagnostic techniques to characterize the plasma flow and improve the understanding of the relationship between arc-jet test and flight environments.

Hypersonic Wind Tunnel built with DURIP grant funding

“It generally takes about 10 years to develop a new heat shield for a hypersonic vehicle, and part of it is due to the uncertainties associated with the arc-jet plasma flow,” Maddalena said. “In other words, you don’t know at what exact conditions you’re testing.”

The new hypersonic wind tunnel is located in UTA’s Aerodynamics Research Center, which also is home to low-speed, transonic, and supersonic wind tunnels, as well as a hypersonic shock tunnel.

Luca Maddalena, UTA aerospace engineering associate professor and director of the Aerodynamics Research Center, inside the wind tunnel. [Photo: UT Arlington]

The wind tunnel was designed and built with a $1.01 million Defense University Research Instrumentation Program (DURIP) grant, as well as substantial funds from UTA. It is dubbed “Leste” after hot winds in the Canary Islands.

An additional $690,000 DURIP grant was awarded in early 2019 to purchase a femtosecond laser system to capture the temperature and composition of the plasma flow. That will be the only one of its kind to be used in an arc-heated wind tunnel in the United States, UTA said. In fact, the laser system is so advanced, it hasn’t ever been used in an arc-jet facility and is currently still being built.

How long is a femtosecond? Not long. It’s one quadrillionth—one millionth of a billionth—of a second. An $818,000 grant also was awarded to develop the laser system and characterize the arc-jet flow, UTA said.

The professor and his students designed almost all parts themselves

Maddalena and his students had to design almost all of the wind tunnel’s parts because the device is so unique. They ran computer simulations to ensure everything would function as expected.

UTA said the team’s greatest challenge was finding manufacturers to produce the heavy components due to the extreme conditions they must withstand. And, Maddalena had to find a company to build the facility, so he hired APS Industrial Service Inc. of Arlington.

Maddalena’s team included post-doctoral researchers Stefano Gulli, Fabrizio Vergine, and Davide Vigano; doctoral students Vijay Gopal and Daniel Palmquist; master’s graduate David Campbell; undergraduate students Cooper Green, Ian Raybon, Rachel Weeresinghe, and Skyla Westphal; and lab manager David Carter.

“No one was on the team just to pass around a screwdriver or a hammer. They performed real research and were instrumental in the successful launch of this new tunnel.”

Luca Maddalena

“I’m very proud of my students, who helped every step of the way,” Maddalena said. “No one was on the team just to pass around a screwdriver or a hammer. They performed real research and were instrumental in the successful launch of this new tunnel.”

The wind tunnel’s unique abilities made it ideal for the Navy’s specific applications. Maddalena said that UTA is the only university in the United States able to reproduce significant skin friction with its facility.

“The Office of Naval Research is proud to be associated with the only arc-jet facility based at a university in the United States,” Eric Wuchina, program officer with the Office of Naval Research, said in a statement. “This facility will allow researchers to develop a deeper understanding of the boundary-layer chemistry and physics under simulated flight conditions of high shear and high enthalpy flows. This will provide valuable data for the aerothermodynamics community and help materials scientists understand the thermochemical response of thermal protection materials in hypersonic flight conditions.”

The UTA community, too, recognized the importance of the wind tunnel.

Jim Shea, UTA’s senior director of corporate relations, tweeted: “This is a tremendous achievement for @UTArlington Engineering, bringing a critical training and educational resource for the DFW defense industry’s hypersonics workforce.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.