When biopharmaceutical companies ship vaccines, biologics, and other high-value medicines, they don’t reach for an envelope. The last thing they want is exposure to excessive heat or cold. That makes temperature-sensitive thermal shipping solutions a critical mission—one that Packaging Technology Group pursues every day.

This week PTG announced it will open a new manufacturing facility in Fort Worth to add capacity, expand its portfolio, and better serve its growing client base.

“This is our third new location in 18 months and reinforces our commitment to partners and clients,” said Bill Blezard, CEO of PTG, in a statement. “One of our core values is relationships, and we’re excited to build new connections in the Fort Worth area, create jobs, and triple our production capabilities.”

Bill Blezard, CEO of Packaging Technology Group [Photo: PTG]

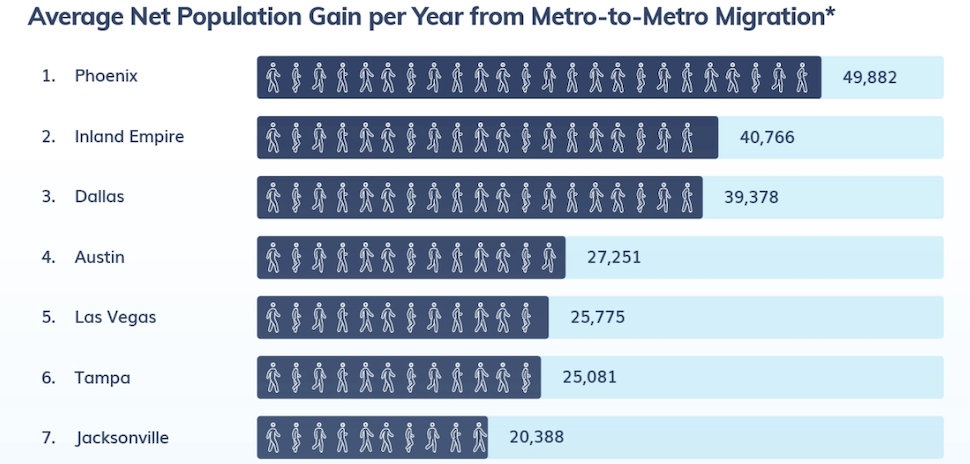

The company—which is privately held by its founder and headquartered in Fall River, Massachusetts—told us it chose Fort Worth because it believes North Texas is “a globally recognized innovation hub.”

“As we expand and grow, we choose cities with robust manufacturing and logistics capabilities, and Fort Worth was the ideal choice as the 13th largest city in the United States,” PTG said. “We currently have 50 employees and will continue to expand. We’re thrilled with the diverse talent pool in the city.”

All-time-high demand

Kelly Cinelli, PTG’s director of marketing, told PharmaTech earlier this summer that demand for their products has never been higher.

“We are finding the demand for single-use, curbside-recyclable shippers for direct-to-patient medication is at an all-time high,” she told PharmaTech. “Reusable shippers also are in high demand due to the COVID-19 pandemic and supply-chain constraints.”

PTG’s 73,000-square-foot Fort Worth facility [Photo: PTG]

Producing and shipping flagship product

The company says operations veteran Ed Kamel is managing the 73,000-square-foot Fort Worth facility. Production kicked off in late August, with Kamel welcoming 17 new PTG employees.

The team is producing and shipping PTG’s flagship product, TRUEtemp Naturals—packaging that’s thermo-efficient, environmentally sustainable, and made with a unique, 100% curbside recyclable insulating fiber to thermally protect high-value medicines, biologics, and vaccines.

In its 17th year of operation, PTG says it serves many of the top pharmaceutical and biologics companies. It’s continuing to engineer, qualify, and manufacture both custom and off-the-shelf shipping solutions.

Tom Lawlor, COO of Packaging Technology Group [Photo: PTG]

Commitment to sustainability

PTG’s sustainability commitment is apparent in its TRUEtemp Naturals and reusable TRUEtemp Last Mile shippers lines. The Last Mile shippers use a proprietary combination of PCM and polyurethane to provide “the ideal solution for the liquid biopsy and cancer diagnostic market.”

“As the demand for eco-friendly products rises, we continue to innovate and create solutions and services for the life sciences industry,” said Tom Lawlor, PTG’s chief operating officer, in the statement. “This new multi-purpose facility offers PTG redundant manufacturing capabilities while substantially increasing our capacity for producing innovative products.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.