Revolution Sustainable Solutions—which both makes and recycles plastics in a “continuous cycle of sustainability”—has acquired PolyAg Recycling, a Canadian mechanical recycler of agricultural films. The goal: growing the footprint of Revolution’s circular solutions across North America.

Revolution is headquartered in Little Rock, Arkansas, and has a strong North Texas presence, including corporate offices in Flower Mound and a manufacturing facility in Mesquite.

“We’re excited about the possibilities that this acquisition brings to Revolution and our valued stakeholders,” Revolution CEO Sean Whiteley said in a statement. “PolyAg has built an impressive business in a relatively short period of time, and by combining our strengths and expertise, we are well-positioned to deliver even more impactful sustainable solutions to our customers in the U.S and Canada.”

Revolution said this strategic move is a significant milestone in its commitment to increase its recycling capacity, as well. Financial terms of the acquisition were not disclosed.

The acquisition is expected to benefit both businesses and the markets they serve by combining PolyAg’s existing operations with Revolution’s extensive resources and expertise in the film recycling space, Revolution said.

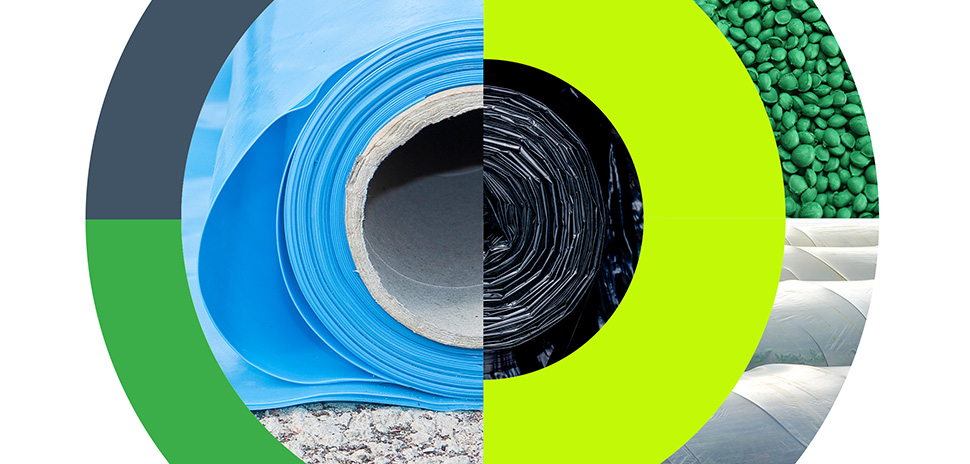

Revolution grain bag [Photo: Revolution]

PolyAg helps farming operations by recycling used agriculture film

PolyAg, of Bashaw, Alberta, began operations in 2019, offering a local recycling solution for used agriculture film—a market where EPR (extended producer responsibility) and product stewardship programs designed to reach a goal of increased recycling have been expanding in recent years.

In Alberta, the Extended Producer Responsibility System went into effect in 2022. Under the program, both governments and non-governmental agencies turned to recyclers like PolyAg to help implement various innovative waste management programs—diverting waste away from landfills and increase circularity in the ag market, the company said.

Acquisition enhances Revolution’s expansion into the agriculture market

[Photo: Revolution]

Revolution said the PolyAg acquisition aligns with its strategic growth goals, including the company’s recent expansion in Little Rock, where it invested in new blown film lines to produce specialty agriculture films. As the company further expands into the ag market, adding PolyAg’s recycling capacity offers significant opportunities to better serve ag customers across the U.S. and Canadian markets with the company’s holistic approach to collection, recycling, and production of sustainable product solutions.

Revolution said it is committed to ensuring a seamless transition for PolyAg and its employees, adding that current PolyAg customers can expect” uninterrupted service and support.”

Acquisition follows Revolution’s September partnership with former Dow unit president

Diego Donoso [Photo: Revolution]

Agriculture, of course, leads to food and food service—so it’s no coincidence that Revolution announced a consulting partnership last fall with Diego Donoso, former president of packaging & speciality plastics at Dow, Inc.

Donoso will support Revolution’s food-grade PCR-LLDPE product line—which the company calls a “breakthrough sustainable solution” in food package goods.

“We’re excited to welcome Diego to the team as a collaborator and partner in our ongoing work to deliver sustainable plastic solutions to the consumer packaging market and beyond,” said Revolution CEO Sean Whiteley at the time. “His extensive experience leading a multinational global company, along with his expertise in the plastics and packaging sector, will undoubtedly raise the bar for our team even higher and propel us forward in developing new relationships, innovations, and solutions for food grade post-consumer recycled polyethylene resin and its many applications.”

Increased demand for recycled content has driven the need for recyclers to meet the quality standards and food contact requirements. Revolution’s advancements in flexible film recycling aims to provide “the widest possible application” to date.

Recent FDA nods have helped company move its mission forward

Revolution received approval to produce recycled PCR for food contact use and introduced food-grade PCR-LLDPE to the market in 2022 after receiving a Letter of No Objection in December 2021 from the U.S. Food and Drug Administration.

Prior to that approval, anyone in the food service industry could use recycled plastic for the bags food containers came in, but not for the food containers themselves.

Being able to have plastic containers holding your food that are made from recycled plastic opens up an entirely new area for recycled plastic, leading to a big step in sustainable consumer packaging.

The U.S. Plastics Pact set aggressive targets to achieve as much as 30% recycled content in plastic packaging by 2025—so the FDA nod could be one way for Revolution and the food industry to help achieve that.

The LNO allowed for Revolution’s proprietary recycling method to produce PCR-LLDPE for flexible films in food contact at content levels up to 100% for all food packaging types under nearly all conditions of use as defined by the FDA.

As the company ramps up processes to meet market demand, Donoso’s extensive expertise will further the Revolution team’s efforts to accelerate the broad adoption and application of existing PCR resin as well as future advancements in recycled polymer production, the company said in September.

Just one month later, we told you about the FDA issuing a new letter of no objection for Revolution’s proprietary recycling method to produce post-consumer recycled, linear low-density polyethylene made from recycled stretch film for food applications.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.