For over 25 years, Toyota has developed fuel cell technology with a goal of achieving carbon-free power—mostly with vehicles in mind. But now it’s exploring ways to scale things up to the megawatt level in a three-year, $6.5 million collaboration with the Department of Energy’s National Renewable Energy Laboratory.

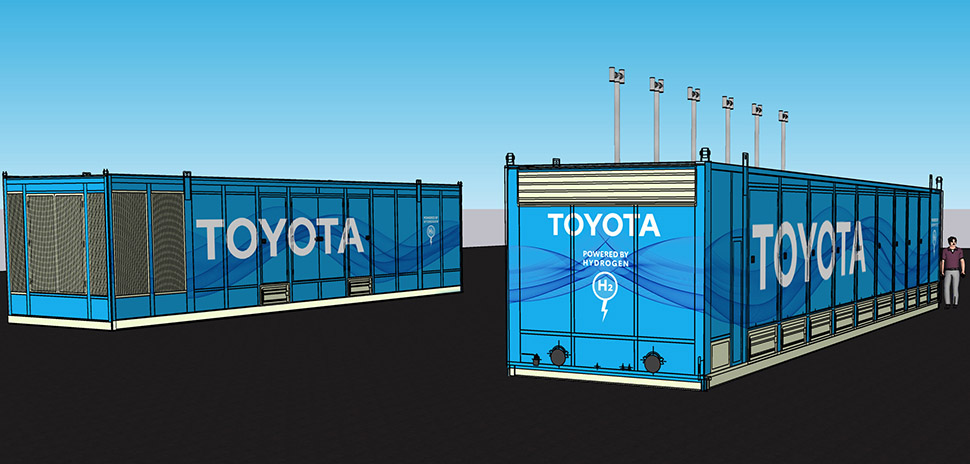

Under the collaboration, Plano-based Toyota Motor North America and NREL will build, install, and evaluate a 1-megawatt proton exchange membrane fuel cell power generation system at NREL’s Flatirons Campus in Arvada, Colorado.

By generating “stationary power,” the fuel cell system can provide continuous energy, add power directly to the grid, and deliver critical backup power for infrastructure. It can also provide power directly to things like data centers, commercial and industrial buildings, and microgrids. All without adding carbon to the atmosphere.

Toyota calls the system a “simplified design” that can serve as a drop-in replacement for a conventional generator. It will be installed this summer, with the full system slated to be commissioned later this year.

NREL already provided fuel cell power for a data center

In a previous collaboration with other partners, NREL showed how an automotive fuel cell system could provide carbon-free power for a data center. But that project would be dwarfed by the new Toyota-NREL project. The new system will scale things up significantly, Toyota says, generating “about 15 times more power” and offering the capability of both AC and DC output.

Christopher Yang, group VP of business development for Toyota’s Fuel Cell Solutions, says taking fuel cell modules meant for cars and combining them on a massive scale can help reduce carbon in the atmosphere.

“Achieving carbon neutrality requires all of us to explore new applications of zero-emission technology, including how that technology will integrate with other systems, which the project with NREL will identify,” Yang said in a statement.

“The application of our modules in deployments of this magnitude shows the scalability of Toyota’s fuel cell technology,” he added, “whether it’s a single fuel cell module for one passenger vehicle or multiple systems combined to power heavy-duty equipment.”

Funded in part by DOE program

The $6.5 million collaboration is funded in part by the DOE’s Hydrogen and Fuel Cell Technologies Office in the Office of Energy Efficiency and Renewable Energy. Toyota’s new fuel cell power system is meant to support the DOE’s H2@Scale vision, which aims to deliver clean hydrogen across “multiple applications and economic sectors.”

Toyota is working with systems integrator Telios on the project

To advance the project in Colorado, Toyota is providing the fuel cell modules and is working with systems integrator Telios for the “design, balance-of-plant, and build of the system for delivery to NREL.”

To maximize the system’s efficiency and longevity, Toyota says it’s developed an integrated control system to manage operation of the fuel cell modules.

‘Pushing the boundaries’ of what the system can achieve

The system Toyota is working on in Colorado will be put through the wringer by NREL researchers to discover its “operational limits.” Their goal is to identify its performance limitations and potential degradation over time. The resulting “real-world data” will help teams develop future applications for the tech, Toyota says.

Other planned R&D assessments will include how the system performs when it’s integrated with energy storage and renewable energy generation systems, including wind turbines and solar panel fields.

“We’ll study the scaling of PEM fuel cell systems for stationary power generation to understand what the performance, durability, and system integration challenges are,” said Daniel Leighton, an NREL research engineer and principal investigator on the project. “This fuel cell generator system also creates a new megawatt-scale fuel cell research capability at NREL.”

NREL’s ‘ARIES’ megawatt-scale hydrogen system

This project isn’t NREL’s first rodeo, not by a long shot. It’s just part of the Advanced Research on Integrated Energy Systems (ARIES) megawatt-scale hydrogen system being designed and commissioned at NREL’s Flatirons Campus.

“The flexible system—which includes a 1.25-MW PEM electrolyzer, 600-kg hydrogen storage system and 1-MW fuel cell generator—provides a platform to demonstrate direct renewable hydrogen production, energy storage, power production, and grid integration at the megawatt scale,” Toyota said in a statement.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.