THE FIRST CERTIFIED HOSPITAL AIRCRAFT PREPARES TO HEAD TO CHINA

From the lasers in the operating room to the 46-seat 3-D classroom, Orbis Flying Eye Hospital crams the latest ophthalmic and broadcasting technology into an aircraft.

The MD-10 is the world’s first certified hospital aircraft developed by Orbis, a nonprofit that fights blindness around the world. The new aircraft stopped by Fort Worth Meacham International Airport last week to pay tribute to Forth Worth-based Alcon and the Alcon Foundation that helped make this possible. Alcon is a subsidiary of the Swiss pharmaceutical giant Novartis.

THIRD GENERATION OF THE FLYING EYE HOSPITAL

Alcon’s equipment and instruments are throughout the plane and the Alcon Foundation contributed $2 million toward the project.

This is actually the third generation of Orbis’ aircraft, but the technology onboard the Flying Eye Hospital goes far beyond its predecessors.

Bettina Maunz, vice president and global head of communications for Alcon and the president of the Alcon Foundation, said she will go on the Flying Eye’s maiden voyage to Shenyang, China this September.

“It means going with the plane into a country with hardly any medical infrastructure.”

Bettina Maunz

“Part of our mission is to increase access to eye care,” Maunz said. “It means going with the plane into a country with hardly any medical infrastructure.”

The Alcon Foundation has been supporting Orbis for 30 years.

Orbis will provide treatments to patients there while also teaching nurses and doctors in that country how they can establish their own eye surgery facility. Maunz said it’s all about sustainability and continuing that eye care after the Flying Eye Hospital leaves.

The aircraft was donated by FedEx, which used it to haul freight. Now, even though it’s a flying hospital, it still retains that freight designation thanks to the modular construction inside, Bruce Johnson, director of aircraft operations for Orbis, said.

Each section of the hospital is a module that can reconfigured, removed or placed on another aircraft, Johnson said.

“This is not technically part of the airplane because it’s actually freight,” Johnson said.

THE CLASSROOM IS AT THE FRONT OF THE AIRCRAFT

Hidden under the hospital floors, it looks like any other FedEx freight hauler with rollers. The cargo door is still on the side of the aircraft. In addition to being flexible, the freight designation is cheaper to get from the Federal Aviation Administration, Johnson said.

Orbis and Alcon offered tours of the aircraft from front to back to show off the new technology.

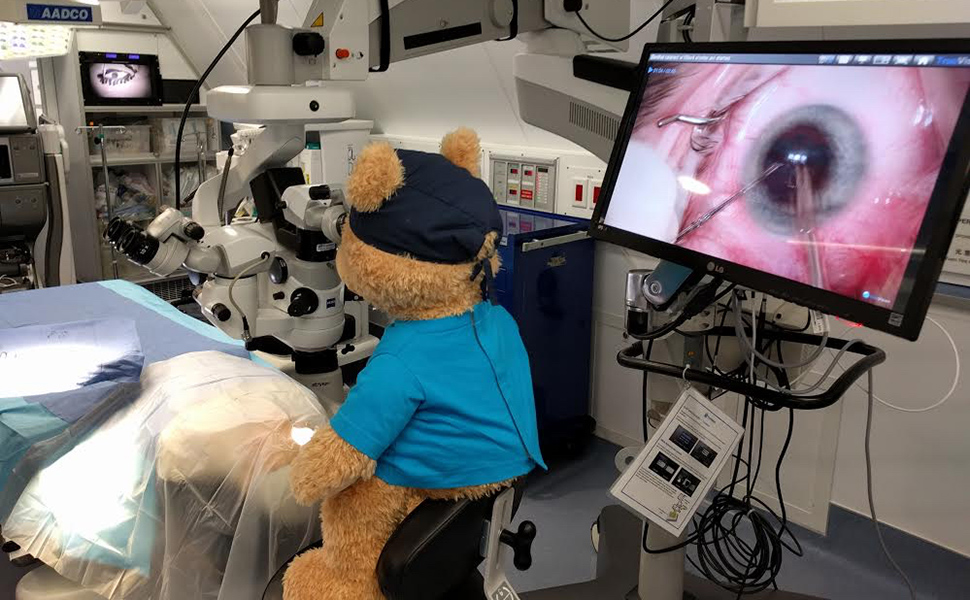

At the front is the classroom that looks similar to a commercial aircraft complete with a flatscreen monitor. But instead of showing movies, it gives doctors and nurses a 3-D view of the surgery going on in the operating room, whether it’s a retinal surgery or removing cataracts.

The airplane can even broadcast the 3-D signal to a bigger audience outside the plane.

Behind the classroom, there’s a diagnostic area with sensitive instruments and a surgical simulator. Dr. Joanne Crosby, a staff doctor for Orbis, showed how the simulator works, removing cataracts on a high-tech video game that uses both hands and feet.

To effectively use the device, doctors need to be ambidextrous.

In the middle of the plane is the operating room, with everything you’d see in a real hospital. While in flight, the operating table, equipment and instruments have to be strapped down in case of turbulence. Once on the ground, everything has to be recalibrated by a biomed specialist.

Next, there’s the sterilization room, complete with special hatches that open to the operating room so doctors and nurses can safely transfer the instruments.

TRAINING LOCAL PROFESSIONAL ON STERILIZATION TECHNIQUES

The dirty instruments are put in a washer in one room and, once clean, they’re picked up in the adjacent sterile room so they can be placed back in the operating room. The sterile room is kept at a higher pressure to keep outside air out.

Like the surgeries themselves, it’s important to train local medical professionals on proper sterilization techniques.

Behind that, there’s the pre-op and recovery room where patients go before and after surgery. There’s also a private changing room at the rear of the plane.

Rob Ranck, president and CEO or Orbis International, said the aircraft will help them fight blindness and other eye disorders by performing surgeries and providing education.

“It is equal parts teacher, enjoy and advocate,” Ranck said. “We harness this powerful tool for change to support long-term programs around the world and we’re delighted to bring it to Dallas-Fort Worth for the very first time.”

The Flying Eye Hospital parked at Fort Worth Meacham International Airport. (Photo Courtesy Orbis)

Dr. Joanne Crosby shows how the surgical simulator works on the Flying Eye Hospital. [Photo Courtesy Orbis]

The classroom donated by Fort Worth-based Alcon Laboratories. [Photo Courtesy Orbis]

The sterile room where instruments are cleaned. [Photo Courtesy Orbis]

The classroom at the front of the aircraft where doctors can observe surgeries in 3-D. [Photo Courtesy Orbis]

For a daily dose of what’s new and next in Dallas-Fort Worth innovation, subscribe to our Dallas Innovates e-newsletter.