California-based chip giant NVIDIA has announced plans to design and build an AI supercomputer factory in the Dallas area, along with a second such plant in Houston. The move by the company and its manufacturing partners will lead to the first NVIDIA AI supercomputers ever to be built entirely in the U.S.

In all, NVIDIA has commissioned more than a million square feet of manufacturing space to build and test supercomputers in Texas as well as NVIDIA Blackwell chips in Arizona.

NVIDIA is doing all this with three manufacturing partners, including Taiwan-based Wistron—which already operates a facility in McKinney and will build the Dallas-area plant—Foxconn, which will build the Houston plant, and TSMC, which has started production on NVIDIA Blackwell at its chip plants in Phoenix, Arizona. (Like Wistron, Foxconn and TSMC are also headquartered in Taiwan.)

Mass production at both new Texas plants is expected to ramp up in the next 12 to 15 months, NVIDIA said. Details of the Dallas- and Houston-area plant locations have not been announced.

Part of a $500 billion push for ‘supply chain resilience’

Within the next four years, NVIDIA plans to produce up to $500 billion in AI infrastructure in the United States, through partnerships with TSMC, Foxconn, Wistron, Amkor, and SPIL, the company said. By deepening its partnerships with these leading global tech companies, NVIDIA is pursuing a goal of “hardening supply chain resilience.”

The impact of the move could not be clearer amid the current raging trade and tariff war between China and the U.S.

“The engines of the world’s AI infrastructure are being built in the United States for the first time,” Jensen Huang, founder and CEO of NVIDIA, said in a blog post. “Adding American manufacturing helps us better meet the incredible and growing demand for AI chips and supercomputers, strengthens our supply chain, and boosts our resiliency.”

Following NVIDIA’s announcement, the White House published its own blog post lauding the news, calling it “the Trump effect in action.”

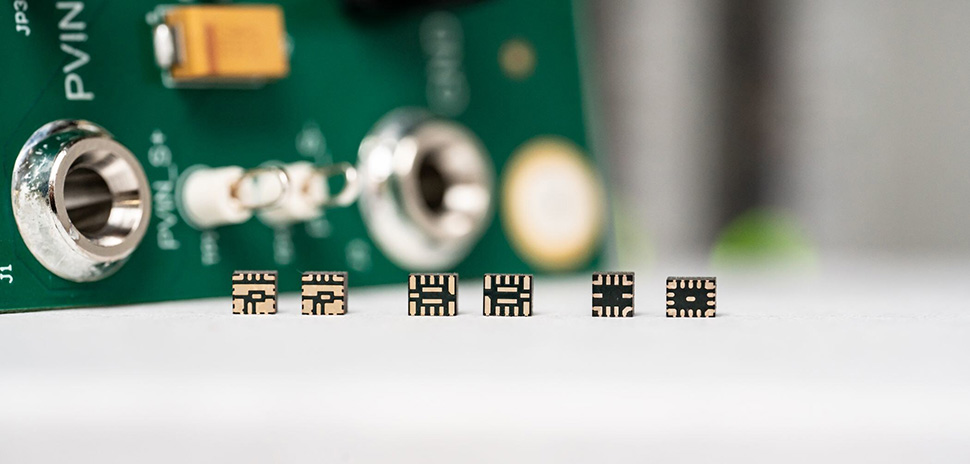

NVIDIA noted that the AI chip and supercomputer supply chain is complex and “demands the most advanced manufacturing, packaging, assembly and test technologies.” The company is partnering with Amkor and SPIL for packaging and testing the Blackwell chips operations in Arizona.

Targeting a new generation of AI data centers

NVIDIA called its AI supercomputers “the engines of a new type of data center created for the sole purpose of processing artificial intelligence—AI factories that are the infrastructure powering a new AI industry.”

Tens of such “gigawatt AI factories” are slated to be built in the coming years, NVIDIA noted. Manufacturing NVIDIA AI chips and supercomputers for U.S. AI factories is expected to create “hundreds of thousands of jobs and drive trillions of dollars in economic security over the coming decades,” the company added.

Digital twins and robotic manufacturing

To build the new plants in Texas and Arizona, NVIDIA will deploy its advanced AI, robotics, and digital twin technologies. NVIDIA’s Omniverse—a real-time, 3D graphics collaboration platform—will be used to create digital twins of the factories for the design-build process. NVIDIA Isaac GR00T—an R&D platform for robot foundation models and data pipelines to accelerate “humanoid robotics”—will be leveraged to build robots that will automate manufacturing.

Dallas’ growing role in semiconductors, ‘fablets,’ supercomputers, and more

The planned Dallas-area supercomputer plant joins a long list of recent high-profile moments for the city in high-tech manufacturing.

Last year, technology holding group G42 announced it was building an “8-exaFLOP AI supercomputer” in Dallas, the third cluster of a constellation of AI supercomputers it’s building with California-based Cerebras Systems.

Wistron GreenTech, Wistron’s facility in McKinney, partnered with New Jersey-based Princeton NuEnergy in 2022 on a 500-ton lithium-Ion battery (LIB) direct recycling pilot production line. Now, with NVIDIA’s new announcement, Wistron will definitely be ramping up its North Texas operations.

In October 2023, the Texoma Semiconductor Tech Hub landed in Dallas as part of 31 nationwide tech hubs designated by the Biden-Harris administration. The federally funded economic development initiative aims to strengthen, build on, and drive innovation in the existing semiconductor supply chain in 29 counties in North Texas and Oklahoma through regional collaboration and workforce development. At the time, Dallas Innovates wrote about how SMU helped snag the Dallas hub’s lead agency role.

SMU doubled down on its own push into supercomputers in 2021. A decade before, SMU had acquired its first high-speed computing cluster from NVIDIA, enabling its researchers to analyze data from CERN. That led to SMU’s role in identifying the probability of the Higgs boson—the so-called “God Particle.” In turn, SMU announced in 2021 that it was investing $11.5 million in hardware, software, and training to crank up the school’s AI infrastructure with an NVIDIA DGX SuperPOD—bringing “world-leading AI supercomputing capabilities” to Dallas.

Fabs galore in North Texas

In Sherman, 60 miles north of Dallas, Texas Instruments is building up to four new 300-millimeter semiconductor wafer fabrication plants, or fabs. With a $30 billion investment and up to 4.7 million square feet at full build-out, the campus would be the largest electronics production facility in Texas.

Also in Sherman, Taiwan-based GlobalWafers announced plans in 2022 for a $5 billion silicon wafer manufacturing plant in the city through its local subsidiary GlobiTech.

In 2022, production began at Dallas-based semiconductor giant Texas Instruments’ newest 300-millimeter wafer fabrication plant in Richardson. Called RFAB2, the plant is connected to RFAB1, which opened in 2009 as the world’s first 300-mm analog wafer “fab.”

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.