Norway-based Visitech AS announced that it plans to build a factory in Allen that will be able to produce its full line of projectors and subsystems for state-of-the-art 3D printing and direct imaging applications in 2024.

The company—which has established an Americas office in Allen, north of Dallas—said that growth in demand for additive manufacturing applications for DLP projectors has created the need for additional manufacturing capacity with an optimized supply chain for customers in North America.

“We’ve invested heavily in R&D and manufacturing capacity to develop the additive manufacturing market with our groundbreaking technology,” Oyvind Tafjord, managing director of Visitech HQ in Norway, said in a statement. “This new facility demonstrates our commitment to our customers worldwide in support of their growth plans and full product lifecycle. Our speed and industrial durability are the result of working closely with our customers and leveraging Visitech’s electronics, mechanics, optics, and software expertise,”

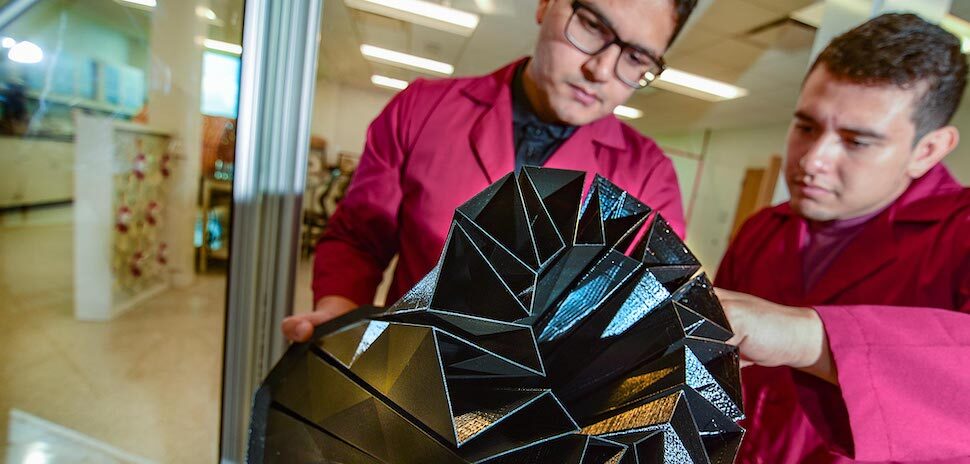

Recently acquired DLP design house Keynote Photonics in Allen

Visitech Americas CEO Adam Kunzman

The company recently acquired DLP design house Keynote Photonics in Allen and announced it had formed Visitech Americas, a new subsidiary for sales, marketing, engineering, and product services in support of the rapidly growing additive manufacturing market in the United States and the Americas.

“We see tremendous potential in a range of 3D printing applications and have participated in the explosive growth in this transformation,” Adam Kunzman, CEO of Visitech Americas, said in a statement. “The recent introduction of our next-generation scrolling projector, the LRS-MCx 4K, which doubles our customers’ machine capacity, is fueling this growth.”

Visitech said its commitment to developing the additive manufacturing market now becomes a complete U.S. factory. This significant investment will secure a reliable supply of critical equipment to the company’s U.S. customers and strengthen product support capabilities within an expanding market, the company said.

Participating in ‘explosive growth’ in additive manufacturing

Visitech Americas HQ in Allen [Photo LinkedIn]

Visitech said it has nearly 15,000 systems installed in machines worldwide in a range of applications such as direct UV imaging for PCB lithography and advanced semiconductor packaging, 3D metrology, and high-performance display subsystems.

It said a typical machine includes four to eight projectors working 24-7 in inline production lines. The Visitech subsystem exposes a photosensitive material while scanning and scrolling over large panels in less than 10 seconds.

Visitech said that experience complements its abilities in additive manufacturing applications – making it a crucial element in developing new technology for the consumer market, life-science applications, and industrial manufacturing.

Visitech said it anticipates its sales to double by 2025, in part because of its new Texas factory and its commitment to developing the additive manufacturing market.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.