The Mark Cuban Cost Plus Drug Company opened its online pharmacy ahead of schedule two weeks ago, offering 100+ generic drugs at manufacturer cost plus a flat 15% margin and a $3 pharmacist fee. Yesterday it reached another milestone in its bid to “disrupt and disable big pharma”—by topping out its pharmaceutical manufacturing facility in Dallas’ Deep Ellum neighborhood.

In one example of the savings the startup delivers, the leukemia treatment Imatinib typically retails at $9,657 per month. But through MCCPDC, the price is offered at only $47 per month.

MCCPDC employees, from left to right: Chris Dietz, Simone Orange, and Adrian Rodriguez. [Photo: MCCPDC]

Speakers at yesterday’s topping-out ceremony included MCCPDC CEO Alex Oshmyansky, Stephanie Hudiburg of the Deep Ellum Foundation, and other project leaders.

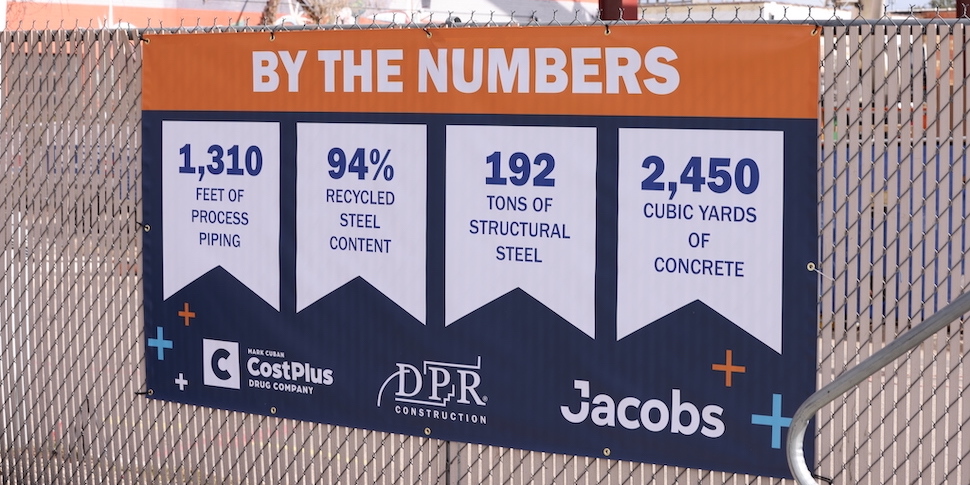

The $11 million, 22,000-square-foot plant is located at 3015 Taylor Street near downtown. The MCCPDC plans to manufacture low-cost, generic versions of traditionally overpriced drugs at the facility. Its initial capabilities will include “supporting the formulation, filling, and packaging of sterile medicines,” with plans to expand into private-label injectables in the future.

Rendering of Mark Cuban Cost Plus Drug Company Plant in Dallas’ Deep Ellum [Image: Jacobs]

The facility is expected to eventually employ up to 80 people, the company says.

The startup also aims for the facility to be a designated site for producing drugs seen by other pharma firms as unprofitable to make.

“The facility’s innovative design will allow for the production of small product batches considered in short supply by the FDA and those intended for treatment of rare diseases that typically affect a smaller population, known as orphan drugs,” Jacobs People & Places Solutions EVP Ken Gilmartin said in a statement last fall.

[Photo: MCCPDC]

Construction began last February with Jacobs providing engineering

Construction on the facility began in February 2021, with the remodeling and retrofitting of an existing building at 302 S. Walton St., the Dallas Morning News reported at the time.

Dallas-based Jacobs won the contract to provide engineering services for the plant construction. The facility will be registered with the Food and Drug Administration to allow ultimate flexibility for rapid response to drug shortages, Jacobs noted on its website. The plant will support the formulation, filling, and packaging of sterile medicines.

[Photo: MCCPDC]

An example of ‘innovation, entrepreneurship, and investment in our communities’

In a statement, Mayor Eric Johnson saw the facility as a symbol of something larger for Dallas.

“Our city must continue to encourage innovation, entrepreneurship, and investment in our communities,” said Mayor Johnson. “The Mark Cuban Cost Plus Drug Company can serve as an important example of all three. I want to thank you for investing in Dallas, helping to grow and strengthen our local economy, and working to address the critical healthcare needs of our residents.”

The man with his name on the sign out front weighed in as well.

“This new facility brings us one step closer to drastically expanding access to life-saving medication,” said Mark Cuban, the majority investor in MCCPDC, in the statement. “By making them ourselves, we’re going to dramatically lower the price of extremely high-cost generic drugs. We’re adding SKUs as quickly as possible—the health equity impact is enormous. I can’t wait to make costplusdrugs.com the go-to pharmacy in the U.S.”

[Photo: MCCPDC]

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.