Stair-climbing vacuums, French presses, and hurdle-jumping poodles might not seem to have much in common with quadcopter drones, firefighting robots, and semi-truck tire lifters. But these wildly diverse projects all sprang from the one unexpected source—the UTDesign Capstone at UT Dallas.

The academic program is a kind of innovation hub, where senior engineering and computer science students from the Jonsson School tackle industry challenges for a spectrum of sponsor companies.

More than one North Texas business leader has dubbed it a ‘best-kept secret.’

Victor Fishman

Dallas Innovates asked Victor Fishman, who heads the Texas Research Alliance, for insight into what sets the program apart. The TRA executive director facilitates public-private and multi-university partnerships to solve business research needs and helps companies to engage with universities to solve problems.

Fishman says the UTDesign program is an opportunity for companies to tap into a talented pool of engineers and computer scientists.

UTDesign matches student teams with industry partners to tackle real-world tech projects each semester. Company sponsors range from startups with tight resources and a backlog of projects to Fortune 500 giants seeking fresh perspectives and talent. (Applications for the 2023 fall semester are open until August 15 for engineering projects. But it’s never too early to explore options, the university says.)

Among the many capstones in existence, the UT Dallas program draws attention for its “well-developed” approach, Fishman said.

Every one of our universities has a capstone process,” he said. And while they’re all driven by ABET accreditation requirements, they’re all structured a little bit differently. The UTDesign capstone has institutionalized a “personalized” process for companies and their interaction with the faculty, according to the TRA director.

Fishman says capstone programs like those at UT Dallas present opportunities that can be game-changers for both students and corporations, carving new pathways for collaboration, innovation, and problem-solving.

According to the TRA director, one of the program’s most powerful features is that its student teams span diverse technologies within engineering: AI, AR, IoT, computer vision, game development, bioengineering, robotics, and software development. And any prototypes and intellectual property developed belong to the company sponsor.

In a project for Denton-based Peterbilt, which also has a primary manufacturing facility located in the region, capstone students developed a tire-install lifting device.

UTDesign’s capstone, it seems, has hit a sweet spot.

Its multidisciplinary approach has fueled a variety of innovative solutions and netted the program an impressive haul of accolades. Since 2014, UTDesign has claimed 10 national first-place capstone awards, the university says.

Last year also marked the eighth consecutive year that a UTDesign team won an award at the American Society of Mechanical Engineers competition.

It’s not just the awards that draw attention.

Corporate sponsors such as Texas Instruments, State Farm, Murata Manufacturing, Cisco, HP, Raytheon Technologies (now RTX), Qorvo, and Capital One regularly return semester after semester.

The program recruited a record number of projects in 2022 from companies of all sizes, including startups.

Fishman says the capstone approach has “real value for small to midsize companies, as well as large ones when they’re trying to solve problems.”

Supporting startups with prototypes, testing, and ideas

Rick Tett, founder of the Plano-based companies Glydr and HoboLoco, has a long history with the UTDesign program. His startup, Glydr, aims to offer a new gaming experience, allowing players to use their feet for in-game movement using HoboLoco technology.

Glydr and HoboLoco Founder Rick Tett developed a game-changing foot controller for gaming, robotics, and more. [Image: Bri Crow]

Tett, a UT Dallas Master’s alumnus, is clearly a believer in the program’s value. “UTDesign Engineering Capstone teams have completed 12 projects for HoboLoco as well as three other projects I was involved in,” he said, noting his work with the aforementioned fire-fighting robot and stair-climbing vacuum.

The capstone has been a linchpin for Tett in areas like prototypes, testing ideas, and even software app creation. But for the entrepreneur, it’s not just about the projects.

Tett made his inaugural hire for HoboLoco after the completion of an early project. Braydon Schramm—employee No. 2 at Tett’s first startup—helped move the startup’s foot controller product design forward while Tett “continued to work full time to pay for patents and parts.”

Tom Coyle

North Texas entrepreneur Tom Coyle also praised his experience with the program, having worked with two “outstanding teams” on different development projects. The CEO of Sciencella, who founded the AI-based medical company, anticipates the student’s work on “key intellectual property” will shape his startups for years to come, he told the school.

As Fishman pointed out, companies own the work created in the program. NDAs may also be a part of the program, given the proprietary nature of the work, according to UT Dallas.

Students shine, companies capitalize

The program started with only eight corporate sponsors in 2010 and now works with nearly 250 companies every year. It’s grown at a fast clip in recent years, considering that 418 companies have sponsored a total of 1,255 projects over the course of 12 years.

Rod Wetterskog, the assistant dean of corporate relations at the Jonsson School of Engineering and Computer Science, is proud of program’s reputation for quality.

Rod Wetterskog

As a “bridge builder” between industry and academia, Wetterskog says the program is a mutually beneficial arrangement for companies and students.

Wetterskog’s career, which includes stints as an optical scientist at Eastman Kodak and an applied physicist at the Superconducting Super Collider, previously managed university relations at Texas Instruments.

Many companies return year after year—or even run multiple projects within a semester, he confirms. Some, such as State Farm, also co-locate their on-campus internship programs at the UTDesign studio.

By the numbers, those companies are satisfied customers: “95% of the companies surveyed said that their experience exceeded or met expectations,” Wetterskog said as the fall semester kicked off last year. “About 60% of those were in the ‘exceeded expectations’ class.”

The problem-solving program is not just a boon for companies: The students get invaluable hands-on experience that can help them get a job—sometimes with the sponsor companies they work with. The companies have the opportunity to “really get to know students and assess their abilities,” the associate dean says. It’s a win-win.

Almost 5,973 students have completed projects to date. “The students are our priority,” Wetterskog said. “We make sure they’re gaining value.”

As he points out, “It’s because of the students that we’ve won so many national awards.”

A pipeline for hiring

Plano-based Toyota Motor North America and Toyota Tsusho Systems have been returning supporters of the UTDesign Capstone program, sponsoring more than 10 projects in the span of just three years, from Spring 2020 to Spring 2023.

“The quality of the students and the program keeps us coming back,” said Stephen McFarland, director of cybersecurity and operations at Toyota North America. The company isn’t only impressed by the “great work” produced by the students, but also values the unique mentoring opportunities that UTDesign provides, McFarland said. The program allows Toyota’s technical mentors to help shape the next generation of industry talent.

Toyota has found the program to be a way to “spot top talent” and has hired several participants. “We’re very pleased with their contribution to our company,” McFarland added. “We would highly recommend this program to other companies.”

Projects from ideation to proof of concept

Sponsor companies give UTDesign students a project scope and a few stretch goals, Wetterskog says. The students ideate potential solutions, and through one or two semesters, they work through preliminary design and proof of concept.

And, yes, there are “crazy all-nighters,” he said.

UT Dallas faculty directors vet projects with experience in computer science, electrical/computer engineering, bioengineering, and mechanical engineering. The directors build the teams and teach the students how to do human-centered design from start to finish, Wetterskog said.

“If you see them talking to students, you’ll be blown away,” he said. “They really pour in.”

‘Students go from being smart to being ready to do real work’

Kris Fitzgerald, chairman of the executive council at UTD Jonsson School of Engineering, says the Capstone program brings value and impact to the community.

Kris Fitzgerald

The retired CTO led R&D and client innovation programs for NTT DATA Services after acquiring Dell Services in 2016.

Not that Fitzgerald has slowed down since then. He’s been called “one of the best technical mentors the program has ever had” and also builds houses for Habitat for Humanity. Fitzgerald encourages companies to leverage the Capstone program. He’s seen students build products that can help companies get to “the next stage” or save time and money. Or all three.

The innovator, who has led large- and small-scale re-engineering efforts in his career, is a valuable fan of the program. “I’ve been on all three sides,” he said. Fitzgerald experienced it first as a hands-on corporate sponsor and later as a faculty advisor.

“The program really helps students go from being smart to being ready to do real work,” he said. They present their results as a team and explain technical matters to executives, he says: Getting feedback from some 35 McKesson executives, for example, is powerful.

“All of these are good outcomes,” he said.

Texas-sized space is a success factor

The UTDesign Studio, which got a makeover in 2022, provides students with more than 45,000 square feet of ideation, fabrication, assembly, test, and meeting space, Wetterskog said in a tour.

Permanent project space and access to commercial equipment in UTDesign’s open lab is an benefit for students.

The studio’s Texas-sized space is a boon for students and companies. In the “open lab,” students have 24/7 access—and permanent project space. That’s an important success factor for the program, Wetterskog says—and a benefit for the many students who also work full time.

That’s a standout difference from other programs, Wetterskog said—and one that students highly value.

At some schools, the lab may be limited in hours and space. “I call those a timeshare,” he said. “Our mindset is different. The university spent $4 million to create the open lab.”

Beyond the lab, students also have access to maker spaces, additive manufacturing tools, such as 3-D printing, and a fabrication shop, with tools like bench grinders and drill presses. That makes studio a top priority, Wetterskong says, and some tools require a special certification.

Violations of rules and procedures are “not three strikes you’re out — it’s just one strike,” he says.

Capstone students who have completed in-person training have 24/7 access to the school’s fabrication shop.

Texas Instruments gets a fab plant lifter

The studio’s dedicated engineering space and access to materials recently helped Richardson-based Texas Instruments get a big project off the ground.

The global tech company has sponsored more than 40 projects since the beginning of the program, according to UT Dallas. But this year, the company had a particularly large-scale challenge that put the studio’s super-sized space to good use.

Mark Simpson of Texas Instruments

Mark Simpson, an equipment engineer for Texas Instruments, wanted to develop a lifting system for the maintenance of heavy equipment in its Richardson fab plant where it makes chips.

The plant’s chillers are about 150 pounds and located under the floor supporting the big equipment that makes the chips, according to the engineer who looks for ways to increase efficiency in TI’s semiconductor processing equipment.

“We were lifting them out by hand,” Simpson said in a video describing the process. “We were lifting them halfway out of the floor to disconnect hoses and wires.”

In other word, it’s a lot of work.

TI had summer interns tackle the problem, but there wasn’t enough time to come up with a good design, Simpson says. The solution was a two-semester UTDesign capstone project that involved several onsite visits to the fab plant.

Student-designed lift system for Texas Instruments on display at UTDesign Expo.

The students “really exceeded my expectations, Simpson says, admitting he “had some doubts at the beginning.”

The lift system is going to help us in our jobs, he points out.

“It’s not just a prototype that gets shelved and never used,” he said. “It’s a real-world solution to a problem that we’ve had.” TI put the lifter in use and plans to build a second one for another local fab plant. “There’s even potential to start building them for fabs around the world,” he said.

The student-designed lifter at TI.

TI, which created the Texas Instruments Innovation Lab within the UTDesign Studio in 2015, is a crucial partner in the capstone program, the school says.

Connecting with UTDesign

UTDesign is one of the most rigorous and successful programs in the country, says Cynthia Heyn, director of corporate relations, for UTDesign. Heyn connects companies with computer science Capstone teams, together with her colleague Don Proeschel and Wetterskog.

Cynthia Heyn

“Our students, in teams of four to six, spend 14 to 28 weeks creating a software or engineering project under the guidance of their customers—our project sponsors,” Heyn said. “They demonstrate that they have what it takes to work in their chosen field, and they make us enormously proud.”

And while capstone programs are offered by many different universities and colleges, the availability and resources of these programs can vary depending on the location, she says.

Heyn says UTD can point to unique advantages, including the aforementioned investment in physical space and open access to its studio resources.

But a truly standout feature is that corporate sponsors can retain intellectual property ownership, Heyn says, calling it a “significant advantage” for companies and individuals who want to commercialize the solutions developed by the student teams.

Multidisciplinary teams are a mix of expertise

The UTD Capstone program gives companies access to students from different engineering and computer science disciplines. This means they can work with a team that has the right mix of expertise needed for tough challenges, Heyn says.

Riyaz Muhammed, a “technical evangelist” with global tech giant Murata Manufacturing, had an idea that “involved a lot of hardware and software” and wanted to “prove it out.”

Riyaz Muhammad

Muhammed, a senior manager of corporate technology and innovation in the tech giant’s office in Carrollton, heard about the UTDesign program and submitted a project that involved predicting the number of people in a particular facility.

In 2021, under Murata’s mentorship, students built an Intelligent Occupancy Management system using air quality measurement through non-intrusive sensing technology to do just that.

It took about a year to get a good foundation using ML and AI: “No one has really done it this far, using carbon dioxide for predicting occupancy,” Muhammed said in an interview last year with UT Dallas’ Don Proeschel.

He has one word for his multi-semester experience with his UTDesign Capstone team: “Fantastic.”

UT Dallas noted the air quality management technology created for Murata could improve people’s lives by helping create healthier public spaces that might boost cognitive function. The system could also help save money on HVAC and other resource costs.

Not solved, but impressive

Companies have also found that the program’s student teams can reveal new insights and possibilities that weren’t previously considered.

![Worlds Inc. CEO and founder Dave Copps [Photo: Michael Samples]](https://s24806.pcdn.co/wp-content/uploads/2020/03/Screen-Shot-2020-03-04-at-6.33.13-PM.png)

Dave Copps

Dave Copps, co-founder of Worlds and a serial entrepreneur with a number of successful exits, teamed up with the UTD sponsor program to take on an AI challenge that he deemed to be near impossible.

While the challenge wasn’t solved, Copps was impressed when the students made significant strides toward addressing the problem and advancing a solution. Copps’ Dallas-based venture is dedicated to providing AI solutions globally.

A ‘juggernaut’ in engineering design

“When it comes to engineering design, UTD is what UCLA once was in basketball,” UT Dallas President Richard C. Benson, has said, calling the UTDesign school a “juggernaut.”

The program has a winning streak to prove it, taking top honors in the past four national competitions, the schools says.

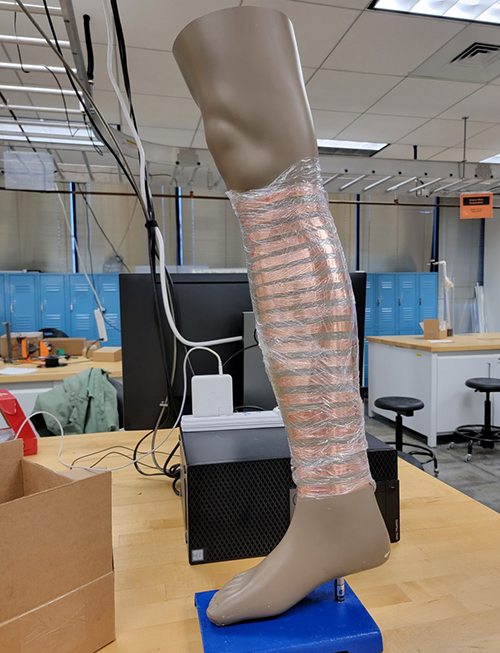

Edgar Acevedo (left), a senior studying biomedical engineering, and Roger Decker III, won a first-place award for their device to help prevent blood clots at a conference last summer. [Photo: UT Dallas]

Every two years, 500 universities with capstone programs are invited to attend, 20 to 25 finalists are chosen to compete in the National Capstone Competition, Heyn says.

Last year, UT Dallas hosted the competition for the first time and notched its fourth first-place award for a corporate-sponsored system designed to test devices that could prevent blood clots after surgery.

A human-calf-shaped ‘surrogate leg’ was created by UTDesign student engineers for Carrollton-based Precision Medical.

A human-calf-shaped ‘surrogate leg’ created by UTDesign student engineers was developed for Carrollton-based Precision Medical; the leg contains rows of copper tape with more than 225 sensing points to visualize pressure and generate over 400,000 unique data points per minute.

Precision says the pressure-sensing device will help the company avoid the expense and delays of outsourcing its testing for post-surgical devices.

Tony Spyropoulos, the company’s EVP of product development, credits the student’s ability to work as a team, which “led to an exceptional outcome that absolutely exceeded our expectations.”

Solutions to diverse design problems

Students solve a mind-boggling array of design challenges for corporate-sponsored projects from innovating household products to facilitating space exploration, according to Heyn.

And yes, hurdle-jumping poodles.

Wiggle clears a hurdle in the agility course during a demonstration of the technology at UT Dallas. The course is designed to motivate pets to exercise for a reward from an automated treat dispenser. [Photo: UT Dallas]

Last year, Capstone projects included everything from an atmospheric plant-watering system for II-VI Marlow to a solder-dipping robot for Micropac to a 3D material waste-recycling device for the UTSW Simulation Center.

Some well-known corporate sponsors, like Lockheed Martin Missiles and Fire Control, were returning companies. Lockheed-sponsored challenges have included a ballistic launch video recording system and a low-cost, portable anti-drone system to protect important areas by disabling unauthorized quadcopters.

Micky Fokken

Others, such as Children’s Health Care Innovation Lab, are relatively new to the program.

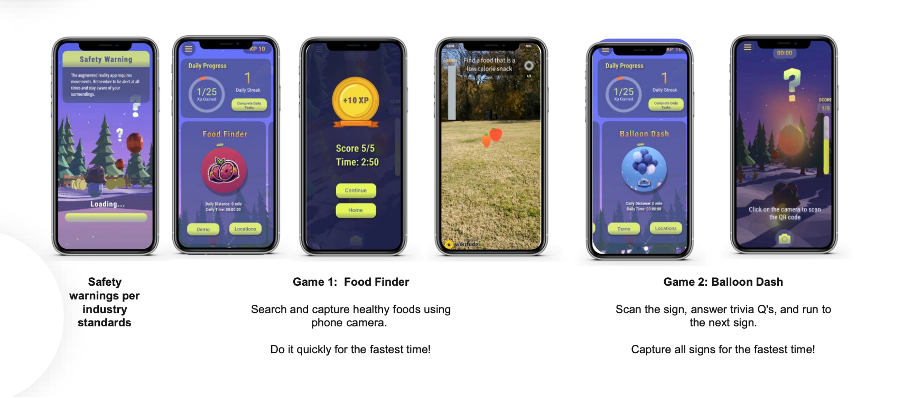

Augmented reality app piloted in Klyde Warren Park

Children’s Health Care’s Mickey Fokken turned to UTDesign when he was reviewing ideas from his lab’s annual hackathon event. Children’s Health wanted to “reverse engineer” the negative association with gaming and show that raising a generation of health-conscious gamers is possible.

The first step was the creation of a mobile app with augmented reality functionalities, the Children’s Health Care innovation director says.

“We were trying to get kids out of the house and moving around,” Fokken has said. “And because most kids like video games, we thought we would leverage the power of gaming, community, and social experiences to get kids to go to parks and play on with the Gamify Parks app.”

Children’s Health sponsored four teams of students for the Gamify Parks Initiative. [Images: UT Dallas]

Fokken, who has numerous projects in the innovation pipeline at any given time, says working with UTDesign was a cost-effective and streamlined way to move game app project forward. The hospital sponsored four teams of students on the Gamify Parks app—one of five separate capstone projects involving a total of 14 capstone teams, UT Dallas said.

But “even though we were kind of figuring out how we could best work together, the students were always really hard workers, and they were also very customer service oriented,” he said, adding that the success of the app initiative wouldn’t have been possible without a program like UTDesign Capstone.

The app featuring mini-games and QR codes—developed by UT Dallas computer science students—was piloted in Dallas’ Klyde Warren Park.

Another company that sponsored multiple teams last fall was Envision Dallas, which provides employment opportunities and programs for people who are blind or visually impaired. Each of its three teams was aimed at making its manufacturing processes more efficient, UT Dallas said.

Students working on the Envision project in the “Texas-sized” lab at UTDesign.

The projects include an automated process for inserting an acetate sheet in retirement binders the company assembles, a retrofit to eliminate the need to refill sewing machine bobbins, and a corner ribbon machine. Students made trips to Envision Dallas to see how the processes were being done and to help them understand the unique needs of blind and visually impaired employees.

How to sponsor a UTDesign Capstone project

To begin a capstone project, a company can contact UTDesign with a real-world problem they need help solving. Then, a UTDesign director will discuss project requirements and details. As the project progresses, the school assigns a team of senior design students to work on the project, Heyn says.

According to the school, the company sponsor plays one of the most important roles in capstone projects. A mentor from the company is a technical point of contact to help the students, while a UT Dallas adviser provides guidance. The student team works together to build prototypes, computer programs, or simulation models depending on the project field.

At the end of the project, the students present their findings and solutions to the sponsoring company and other stakeholders in an expo. UT Dallas says the company retains full ownership of the results from the project, and the students have real-world experience to prepare them for their future professions.

The cost of a one-semester computer science project is $10,000 and a two-semester computer science projects and all engineering projects are $15,000.

Advice for first-time organizations

Micky Fokken of Children’s Health, who has run multiple teams in a semester, offers advice for first-time organizations looking to partner with the program: “The first thing I would say is to make sure you have technical mentors. The second thing is being very clear on the requirements. And then the third thing is to make sure you still have a project manager to keep the project moving along.”

Go here to learn more about the UTDesign Capstone and how to apply.

For more project ideas, check out 17 notable UTDesign capstone projects here. If that’s not enough inspiration, you can find and sort through past projects on the UTDesign website.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.