Chemical weapons are one of the gravest threats faced by the American military and civilians alike. But sensors developed by University of North Texas scientist Guido Verbeck and UNT student Camila Virgen may make all of us a little safer.

INVENTION

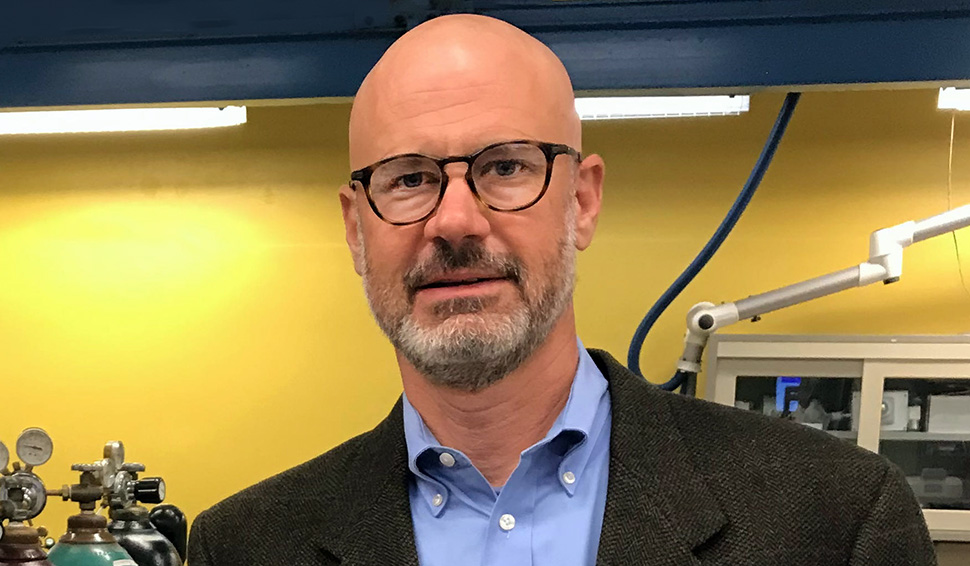

Sensor Scientist

Guido Verbeck

Verbeck and Virgen collaborated with Swiss-based Inficon, which creates gas leak-detecting sensors, to test next-gen instrumentation for chemical weapons detection. Last month, Verbeck and his team tested their tech at the U.S. Army’s Dugway Proving Grounds in Utah. The army hosts an annual S/K Challenge for U.S. and allied nations and companies to show off their solutions for chemical and biological defense systems.

“The results were phenomenal,” Verbeck told Dallas Innovates, and showed “just how well our instrument performs.”

The technology is just one of many breakthroughs that Verbeck, a professor of chemistry and biochemistry at UNT, and his team have pursued in the last year.

A drone that flies over chemical fires

In the realm of sensors for chemical fires, Verbeck and his UNT group are also designing a drone with a mass spectrometer to help firefighters know what chemicals are burning. The drone will give them live IR images to help them respond appropriately.

Verbeck, who earned his Ph.D. in chemistry at Texas A&M, is an expert on innovative uses of mass spectrometry. Last year, his peer-reviewed research on using the technology to detect COVID-19 was accepted and published by the Royal Society of Chemistry.

Detecting toxins in CBD

Verbeck also recently co-authored a study on methods of creating Delta-8, a derivative of CBD, as “pot producers are pushing to clamp down on Delta-8 THC and its cheap, unregulated high.“

Per Bloomberg News, contaminants can show up during manufacturing when Delta-8 is extracted from CBD by mixing it with acid. “The home-brewing methods, which have earned some Delta-8 a reputation as the bathtub gin of the cannabis world, can introduce toxins such as lead,” according to Verbeck. Even higher-quality extraction methods can leave behind potentially harmful compounds like chlorine and sulfates.

“It’s become almost too enticing for there not to be an issue,” Thomas Kiselak, one of Verbeck’s co-authors and a UNT graduate research assistant, told Bloomberg News. “All you need is a little battery acid or pool acid, which a teenager can go and buy. It’s something you can do in about an hour.”

COVID-19 breathalyzer test

Last year Guido Verbeck and his group at UNT developed their chemical sensor, then teamed with Dallas-based Worlds Inc. to turn it into a rapid COVID breathalyzer test . By detecting unique volatile organic compounds, the invention “fingerprints” the virus.

The technology was initially developed to look for chemical variants in the air, as in a fire, drugs in a car, or mass graves, said Verbeck.

Beyond COVID, that means the device has potential groundbreaking applications of “sniffing out” other dangerous diseases like cancers and diabetes.

Diagnosing diseases with a sensor

“Creating a device that can look for not only respiratory illnesses, but also early-stage cancer markers and metabolic disorders in real time could really change the diagnosis field,” the professor says. “Because of this large application set, it was important to use AI and machine learning.” This was what made Worlds such a great partner in the breathalyzer project last year.

The COVID-sniffing sensors are now in use by Inspect IR, a Frisco company that was already using Verbeck’s UNT lab’s technology for portable breathalyzers detecting opioids and cannabis. The Indoor Football League’s Frisco Fighters partnered with InspectIR to conduct weekly COVID screenings of players and staff.

InspectIR Systems, a research, development, and device company based in Frisco, has developed patented technology through a strategic partnership with Dr. Guido Verbeck and the University of North Texas.

What’s next for the busy professor? He’s developing a new device for cancer treatment and one for increasing organ viability for transplants while continuing to pursue a host of new metabolic disease markers for his chemical sensor.

Meet the innovator

Guido Verbeck was featured in Dallas Innovates’ Future 50 in Dallas-Fort Worth in the 2021 edition of our annual magazine. We recently caught up with Verbeck about the COVID-sniffing sensor he created, potential future applications for chemical sensors, and maintaining a strong research team. Here’s a takeaway:

On the chemical sensor he developed for COVID:

The membrane inlet system developed here is tuned specifically for a class of chemical compounds that are released upon cell death due to the SARS-CoV-2 virus. Different viruses have different mechanisms for this process, and thus produce different volatile organic compounds (VOCs). This can be used as a “fingerprint” of the virus, as the instruments detect the masses associated with each chemical compound. So there is chemical selectivity by the membrane, then the mass spectrometry sorts these compounds.

The chemical sensor for the COVID application was developed initially to look for chemical variants in the air. My group developed applications for environmental monitoring, the drug sniffing car, and chemical plume detection coupled to drone and UAV applications (detecting chemicals burning in a fire for instance, or locating mass graves from the chemical signature). These principles of air monitoring for unique chemical fingerprints then were directly applied to breath chemistry, and hence the use for disease detection. The patents surrounding the instrumental portion come from my group and UNT.

On how these chemical sensors can change the future of diagnosing diseases:

Breath analysis is starting to trend as a diagnosis tool for a myriad of disease states. Breast cancer, diabetes, lung cancer have already been determined to own breath markers. Creating a device that can look for not only respiratory illnesses, but also early stage cancer markers, and metabolic disorders in real time could really change the diagnosis field. Because of this large application set, it was important to apply AI and machine learning to the problem. This is why Worlds [was] such a great partner.

On the new UAV chemical sensor to help in fire assessment: This flying mass spectrometer will help fire fighters and first responders know exactly what is burning (chemically), and combine this with Infrared technology to give the first responders a fuller picture of what is going on, so they can respond appropriately. Many fires are started chemically, especially clandestine drug lab, and so the fire fighter would know this before entering.

On teamwork during the pandemic:

We have really been blessed during this time. My lab is quite extensive and spread out over three buildings, so it was very easy for us to keep working during lockdowns. UNT wanted to resource anyone working on the COVID problem, and so we were able to continue our work. I also spent much time with my students to continually encourage them and give them all a positive purpose to help during these trying times.

On his next big projects:

I am an instrument developer, so am working on a couple of very interesting problems. We are developing devices for Remote Smell, In-Surgery Nanoparticle Deposition for Cancer Treatment, Increasing Organ Viability for Transplants, and Broadening the Range of Metabolic Markers for Other Disease States.

A version of this story was originally published in Dallas Innovates 2021: The Resilience Issue.

Read it online

Our fourth annual magazine, Dallas Innovates 2021: The Resilience Issue, highlights Dallas-Fort Worth as a hub for innovation. The collective strength of the innovation ecosystem and intellectual capital in Dallas-Fort Worth is a force to be reckoned with.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.