Dallas-based ACT-ion Battery Technologies, a battery material manufacturing innovator, has leased a factory space in Carrollton to house a “state-of-the-art” pilot plant aimed at scaling its manufacturing process for cathode active materials (CAM) used in next-gen batteries for electric vehicles and energy storage.

The Hunt Energy Enterprises spinout—which closed a $7.5 million Pre-Series A funding round in February—called the new plant “a critical step” in its mission to commercialize its technology, which aims to significantly reduce the cost, environmental impact, and manufacturing time of essential battery components.

“This pilot plant is a pivotal moment for ACT-ion. It’s where our vision for a cleaner and more economical battery future begins to take physical form,” ACT-ion Co-Founder, CEO, and CTO Jin Lim said in a statement. “We’re developing a process that will revolutionize CAM production, a critical bottleneck in the battery supply chain.”

Carrollton site ‘a strategic decision’

Lim said choosing the Northwest Dallas suburb of Carrollton for the plant was “a strategic decision.”

“The city’s proactive support for innovation and its prime location in a major logistics hub provide the ideal environment for us to scale our operations and attract top talent,” he said. “We’re excited to build our foundation here and contribute to the region’s growing reputation as a center for clean energy technology.”

The pilot plant is slated to create new high-tech jobs while strengthening the local supply chain for the rapidly expanding electric vehicle and energy storage sectors.

Carrollton Mayor Steve Babick said ACT-ion’s investment in advanced battery materials “is not only a win for our local economy, but also a step toward strengthening the clean energy supply chain right here in our community.”

“We look forward to seeing the impact their growth will have in furthering city council’s vision of Carrollton as the place businesses and families want to call home,” the mayor added in a statement.

Aiming for more efficient, greener battery component production

ACT-ion said its innovative manufacturing process aims to address “key challenges” in the battery industry— eliminating byproducts and reducing energy consumption, water usage, and the overall physical footprint associated with traditional CAM production.

The scale-up of ACT-ion’s technology has gained support from the U.S. Department of Energy’s Advanced Materials & Manufacturing Technologies Office and Vehicle Technologies Office, the company noted.

ACT-ion said its rapid continuous process produces coated single crystal CAMs for lithium batteries through a “novel, clean, and chemistry-agnostic process, requiring lower energy and cost.”

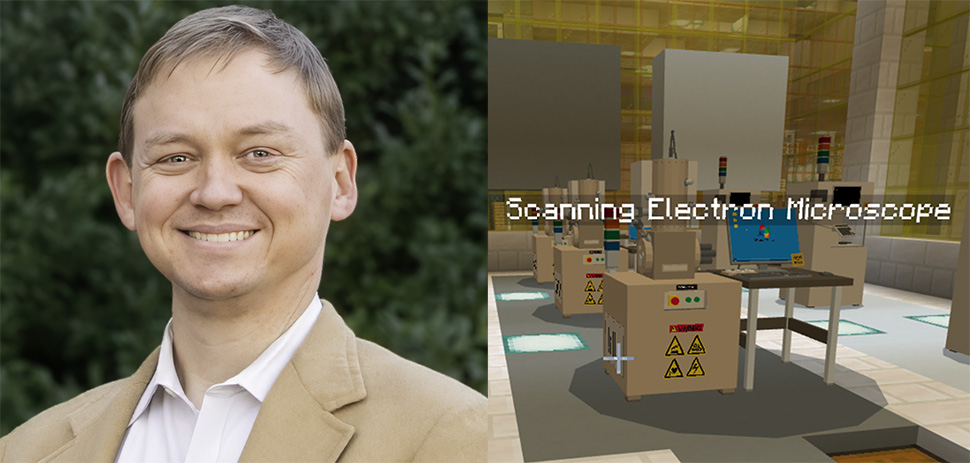

In February, the ACT-ion hired former Tesla executive Anthony Thurston as chief operating officer. He had spent five years leading Tesla’s Cathode Materials and Manufacturing operations globally, including the high nickel cathode Gigafactory in Austin. Before Tesla, Thurston held prominent R&D leadership roles at Apple and BASF.

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.