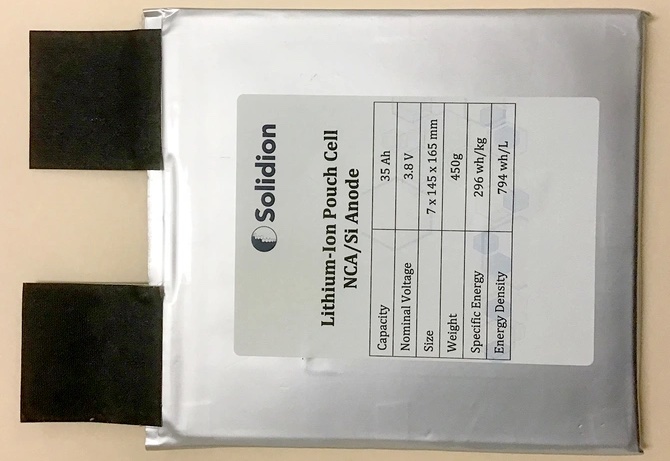

One of the biggest things holding back the wider adoption of electric vehicles is the cost, weight, and charging time of the batteries that zip them down the road. Many car buyers are waiting for the next shoe to drop: the arrival of next-gen, solid-state EV batteries. An announcement by a Dallas-headquartered company aims to move the needle on that front.

On Tuesday, Solidion Technology, an advanced battery technology solutions provider, unveiled its patented bipolar electrode-to-pack (BEEP) technology. Aiming to simplify the design and manufacture of solid-state batteries, the tech “produces a high-voltage, high-capacity battery pack by stacking and connecting bipolar electrodes and solid electrolyte layers in series and in parallel,” the company said.

A Solidion Lithium-Ion pouch cell [Photo: Solidion]

Solid-state batteries could transform the EV industry by offering greater safety, faster charging, and what Soldion calls “an achievable range of over 900 miles on a single charge.” But the company notes two major issues that have so far prevented the widespread commercialization of solid-state lithium batteries—”the difficulty and high cost of manufacturing the batteries and the limited space available in an EV to accommodate a bulky battery system.”

Current EV battery pack designs fill up a lot of that space with fire mitigation solutions, a large number of connectors between cells or modules, and bulky protective housing.

Solidion says its BEEP platform solves that space challenge and simplifies manufacturing, “while contributing to a dramatically reduced battery weight, volume, and cost.” The BEEP technology pack requires only one casing and a small number of connectors, instead of the hundreds of housings and connectors in today’s EV batteries.

“Solid-state batteries are the future of the EV market, but commercialization has been held back by design and manufacturing-related challenges,” Solidion Board Chairman and Chief Science Officer Dr. Bor Jang said in a statement. “The internal bipolar electrode stacking in our patent-protected BEEP technology is intrinsically simpler and easier to develop as compared to making individual cells and using external cables to connect multiple pre-fabricated cells. Solidion’s BEEP technology has the ability to deliver significantly improved manufacturability and reduced manufacturing cost—ultimately leading to a faster route to commercialization.”

Solidion listed on Nasdaq in February via SPAC merger

Solidion Technology Chairman and CEO Jaymes Winters rang the closing bell at Nasdaq on Feb. 9, 2024. [Photo: Nasdaq]

While Solidion is headquartered in Dallas, its pilot production facilities are located in Dayton, Ohio.

Solidion Technology began trading on Nasdaq in February (ticker: STI) via a $700 million merger between Dayton-based Honeycomb Battery Co. and Dallas-based Nubia Brand International, a special purpose acquisition company. Honeycomb was founded in 2015 by Dr. Jang and became a fully owned subsidiary of Global Graphene Group in 2016.

“Electric vehicles will continue to grow global market share over the next decade,” Dr. Aruna Zhamu, Solidion/HBC co-founder and technical adviser, said in February. “Our EV battery technologies, including Si-anode, are very attractive to EV manufacturers. It’s a drop-in solution that can easily be incorporated into existing manufacturing processes. We’re engaged with many top-tier OEMs now validating our solutions.”

Solidion says it holds over 525 patents globally, with 355 in the U.S. and 170 in various foreign jurisdictions. The patents originate from Honeycomb and Global Graphene Group and cover next-generation battery technologies.

You can read more about Solidion’s use of silicon anode for lithium-ion batteries in our February story.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.