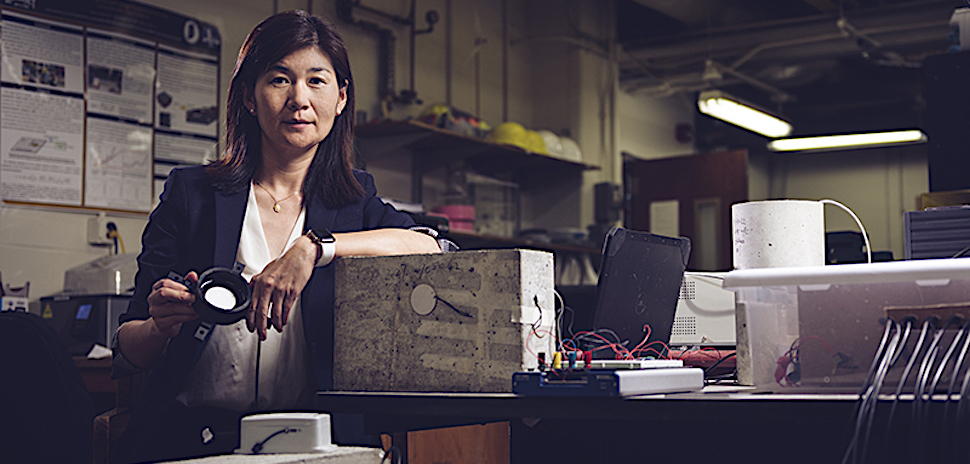

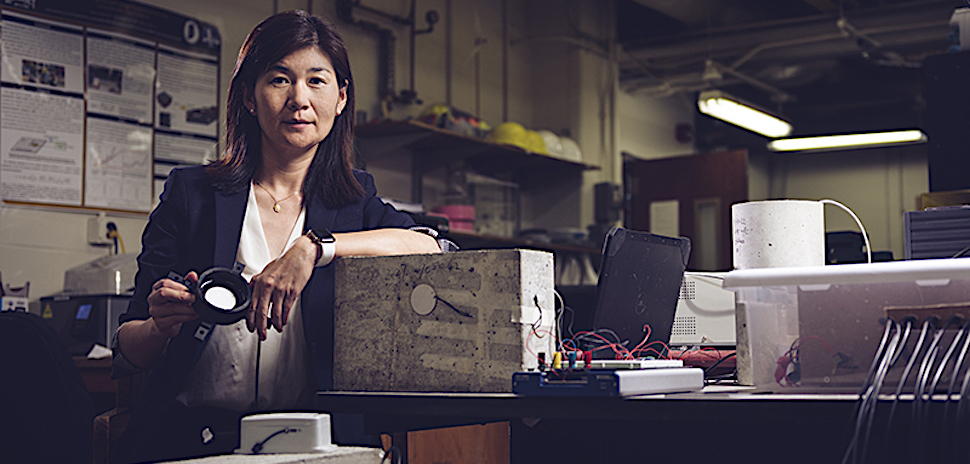

Purdue researcher Luna Lu developed the technology, which is now being tested on I-35 in Hillsboro. [Purdue University photo: Rebecca McElhoe]

Sensor tech that allows concrete to “talk” is now being tested on a stretch of I-35 in Hillsboro—and if the test is successful, it could change testing methods the construction industry has used for over 100 years.

The tech has been in development since 2017 at Purdue University in Indiana, led by researcher Luna Lu. When it’s embedded into a concrete pour, the sensor can send data about the concrete’s strength and potential repair needs more accurately than methods that are now being used, Lu’s team says.

Instead of relying on concrete samples to estimate when newly poured concrete is mature enough for traffic to drive on it, engineers can monitor the fresh concrete directly through the sensor tech.

An early prototype of the sensor was embedded on highways in Indiana, before the tech began being tested on highways in Texas.

Why North Texas was chosen as a testing site

So why did Purdue’s research team choose North Texas as a testing site?

Because the Lone Star State is “leading other states in terms of the innovation of transportation,” Lu told WFAA. She also said Texas’ large size and its room to expand sensors on highways led to Hillsboro having a stake in the possible future of concrete.

WFAA noted that the tech could eventually save taxpayers millions of dollars by, in Lu’s words, helping to “accelerate the construction schedule to about 30 to 35%.”

Additional states are expected to join as the study kicks off in the coming months.

Tech to hit market later this year

According to a Purdue University post, Lu’s technology is on track to hit the market later this year as the REBEL Concrete Strength Sensing System, a product of WaveLogix. Lu founded WaveLogix in 2021 to manufacture the technology on a larger scale. The company licenses the technology from the Purdue Research Foundation Office of Technology Commercialization, which has applied for patent protection on the intellectual property.

“Traffic jams caused by infrastructure repairs have wasted 4 billion hours and 3 billion gallons of gas on a yearly basis,” Lu said in the post. “This is primarily due to insufficient knowledge and understanding of concrete’s strength levels.” Her tech aims to help reduce that waste—and potentially help cut carbon emissions globally.

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.

R E A D N E X T

-

Konsta-Gdoutos is exploring a way to turn one of the world's biggest polluters—concrete, which accounts for at least 8% of global energy-related CO2 emissions—into a source of clean, renewable energy. “We will pioneer TE-CO2NCRETE, a thermoelectric carbon-neutral concrete, that will exhibit a high carbon dioxide uptake potential and storage capacity,” Konsta-Gdoutos said in a statement. “Engineering the nanostructure of concrete also will allow the material to capture thermal energy from the surroundings and convert it into usable electrical energy, leading to the development of a novel technology for renewable electricity and higher efficiency power source.”

-

The startup's nail painting robot provides a "fast-casual" version of a manicure.

-

UT Arlington civil engineering researcher Warda Ashraf is looking to the past to create a concrete-like material for the future—one that could reduce the carbon emissions created by today's construction industry. The ancient Romans used volcanic ash to make structures that still stand today. With $747,000 in DARPA funding, Ashraf's team found a workable substitute—super-heated clay hydrated with lime and seawater—and is preparing to test it in the Corpus Christi Bay area. “We have the recipe. We tested that in the laboratory," Ashraf told Dallas Innovates. "Now, let's put it in the field and see what happens.”

-

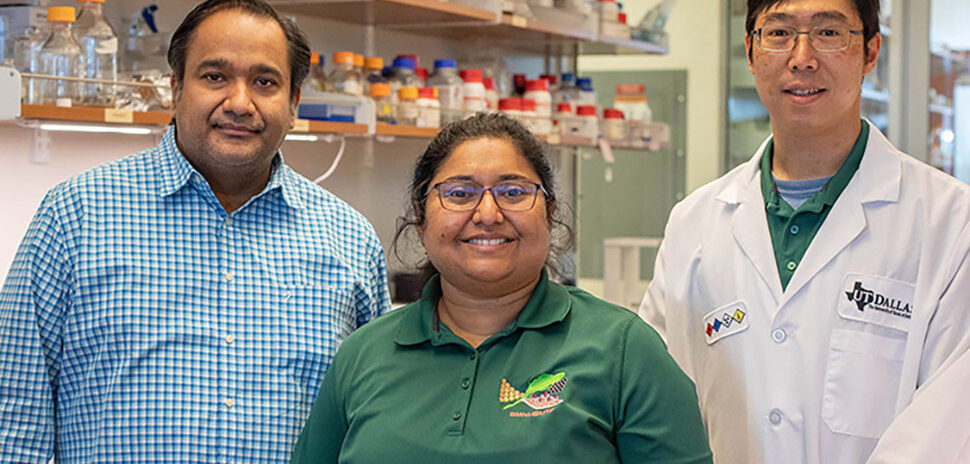

A team of UT Dallas bioengineers in collaboration with Allen-based EnLiSense designed the device, which uses an electrochemical biosensor to detect two key biomarkers of infection. The sensor could be a "significant step" toward early detection of infections like COVID-19 and the flu. "We have built a technology to unlock and explore the latest frontier in sweat diagnostics," said Dr. Shalini Prasad, who heads up the UTD team and is a co-founder of EnLiSense.

-

“It’s thrilling to see the Proto M step out into the real world.” David Nussbaum Inventor and Founder Proto Inc. .…on bringing the first public activation of Proto's new hologram device to Dallas Proto Inc. is the creator of technology that makes hologram-based communication a reality. With awards from CES, SXSW, and Fast Company, the Tim Draper-backed startup is the innovator of a plug-and-play, self-contained holoportation device. Nussbaum's original holoportation device, a human-sized Epic (above) has grabbed headlines for beaming people around the world in 3D, lifesize form. Now it's launched a mini-me version of the Epic called the Proto…

![]()