Musculoskeletal disorders account for nearly 30% of all workplace injuries in the U.S., costing an estimated $45 billion to $54 billion each year in medical recovery and workers’ compensation, according to The University of Texas at Arlington.

Engineers at UTA are working on a potential way to reduce that toll. The research team has developed a soft robotic exoskeleton designed to support workers who spend hours lifting materials or performing repetitive upper-limb tasks.

The device—called the Pneumatically Actuated Soft Elbow Exoskeleton, or PASE—uses a lightweight silicone pneumatic actuator to assist arm and elbow movement during common industrial activities such as lifting, assembly, and drilling. Its flexible, wearable design is intended to reduce muscle load in the upper arm and lower the risk of injury over time.

Study results show reduced muscle activity

In testing, the device showed measurable reductions in muscle strain during common industrial tasks.

UTA researchers evaluated PASE in a study involving 19 participants between the ages of 18 and 45. Participants performed three typical workplace activities—manual weightlifting, basic assembly, and power drilling—with and without the exoskeleton’s pneumatic assistance engaged.

When the device was active, muscle activity in the biceps and triceps decreased by as much as 22% during lifting tasks, according to UTA. Participants also reported reductions of eight to 10 points in perceived physical and mental workload, as measured by NASA’s Task Load Index.

“Even delaying or preventing a single workplace injury makes a huge impact,” said Veysel Erel, who leads soft robotics research at the UTA Research Institute. He said the findings demonstrate how wearable robotics can help reduce fatigue, prevent strain, and improve safety in industrial environments.

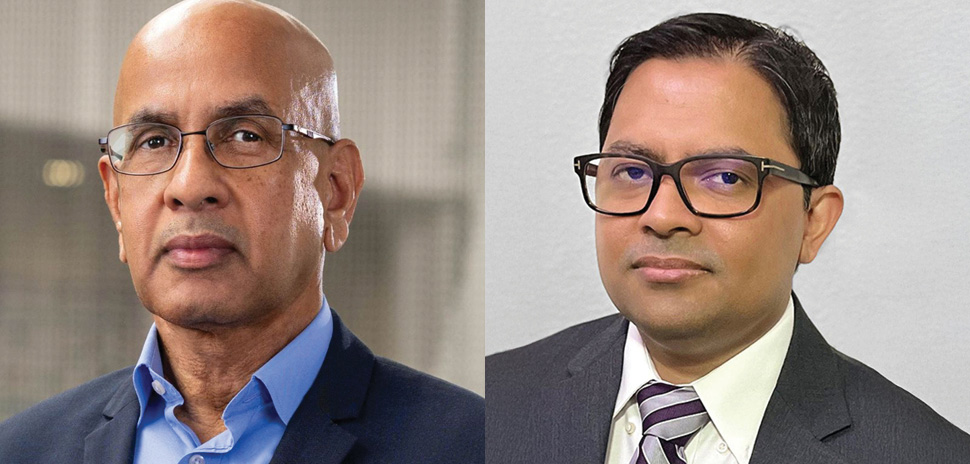

Muthu Wijesundara (left), principal research scientist and division head of biomedical technologies at the UTA Research Institute, and Mahmudur Rahman, assistant professor of industrial, manufacturing, and systems engineering at The University of Texas at Arlington, are part of the interdisciplinary team behind a soft robotic exoskeleton designed to reduce muscle strain in industrial work. [Photos: UTA]

A soft, air-powered approach designed for industry

Unlike rigid exoskeletons, PASE relies on a single-piece pneumatic actuator made of silicone and mounted on a carbon-fiber onyx base plate, with a soft neoprene outer layer. The system is powered by compressed air—equipment already common in many manufacturing facilities—making it easier to deploy in real-world work environments, UTA said.

“Our goal was to create a preventive, assistive device that reduces muscle strain before injuries occur,” said Eshwara Prasad Sridhar, a graduate research assistant in UTA’s Department of Industrial, Manufacturing, and Systems Engineering.

By using pneumatic systems already available overhead in many factories, Sridhar said, the exoskeleton can be integrated without requiring major changes to existing infrastructure.

The interdisciplinary project was funded by UTA’s Interdisciplinary Research Program and led by Mahmudur Rahman, assistant professor of industrial, manufacturing, and systems engineering. The research team also included Muthu Wijesundara, principal research scientist and division head of biomedical technologies at the UTA Research Institute; Erel; and Sridhar.

Published findings and next steps

The study, “Design, Development, and Evaluation of a Pneumatically Actuated Soft Wearable Robotic Elbow Exoskeleton for Reducing Muscle Activity and Perceived Workload,” was published in the Journal of Rehabilitation and Assistive Technologies Engineering.

Building on those results, the team has submitted a proposal to the National Science Foundation to expand the concept into a full upper-limb exoskeleton that could assist the elbow, wrist, and fingers simultaneously.

“This type of interdisciplinary research is at the heart of UTA’s mission,” Erel said. “By combining expertise across robotics, mechanical engineering, and human factors, we’re creating solutions that address real challenges in both industry and everyday life.”

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.