Texas Instruments plans to deploy humanoid robots from China’s UBTECH Robotics on its semiconductor production lines, according to reports by the Chinese Securities Times and other media outlets.

According to the reports, TI has purchased UBTECH’s Walker S2 robots in a deal that could lead to a reciprocal supply chain partnership between the two companies. As TI works to deploy the robots on its chip production lines, UBTECH will aim to use additional TI components in its robots.

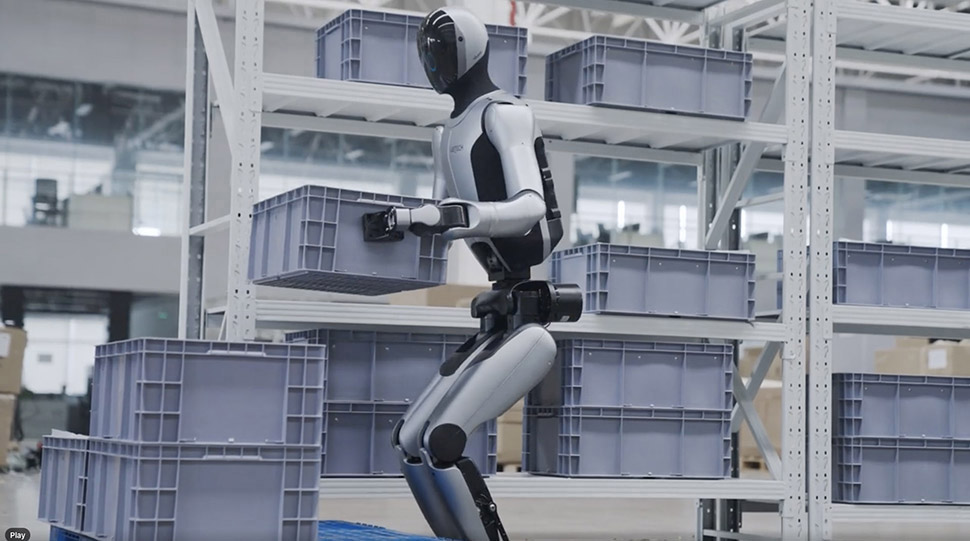

UBTECH’s Walker S2 robot [Video still: UBTECH]

Dallas-based TI could use the help. Just last month, the company started production at its newest 300mm semiconductor fabrication plant in Sherman, a city 50 miles north of Dallas. Called SM1, the fab will ramp up production according to customer demand, TI said, and will ultimately produce “tens of millions of chips daily that go into nearly every electronic device”—from smartphones, automotive systems, and life-saving medical devices to industrial robots, smart home appliances, and data centers.

While the Walker S2 robots work on chips for TI, they’ll also be working on aviation manufacturing for another huge global company. Last week, news broke that Shenzhen-based UBTECH is partnering with Airbus to bring its humanoid robots to Airbus’ aviation manufacturing plants.

Two Walker S2 robots from UBTECH Robotics at work. [Video still: UBTECH]

UBTECH’s robots moving from EVs to chips

UBTECH’s industrial robots have primarily been working in Chinese electric vehicle plants until now, according to the robotics news site Humanoids Daily, with its humanoids deployed at BYD, Geely, and FAW-Volkswagen facilities.

The company’s expansions to work on semiconductors for TI and aviation manufacturing for Airbus are the latest moves in a global shift toward complementing—or replacing—human workers across industries.

‘Human-eye’ perception—and it swaps its own batteries

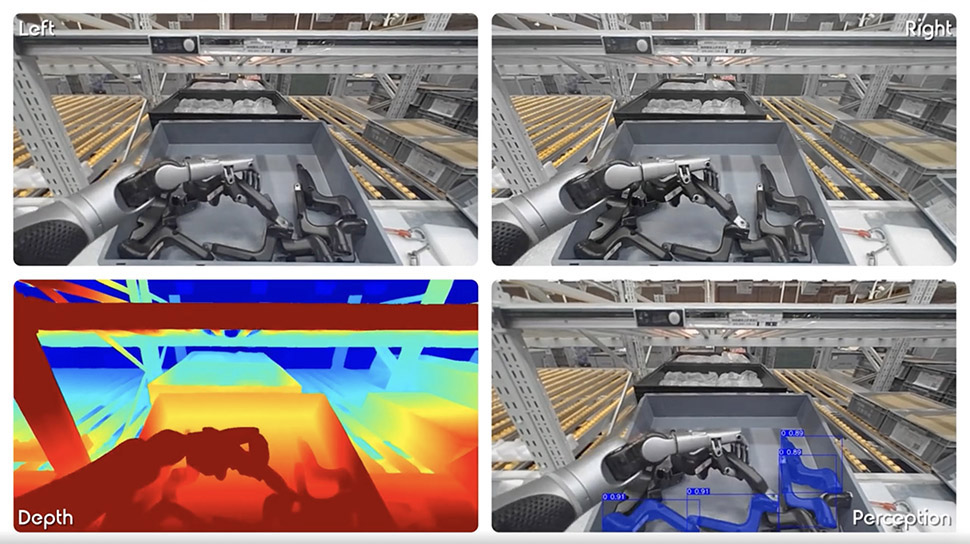

POV of UBTECH’s Walker S2 shows “human-eye” binocular stereo vision perception. [Video still: UBTECH]

UBTECH’s Walker S2 robots are 5 feet 9 inches tall, and come packed with impressive tech. They’re powered by a dual-loop AI system that enables both single-agent autonomy and multi-robot collaboration.

They don’t just walk, grab, and move—they can “see” in ways that enable the performance of detailed factory tasks. The company says Walker S2 is the first humanoid robot to feature an RGB stereo vision system, delivering “human-eye” binocular stereo vision perception “for enhanced adaptability in complex factories.”

The humanoid’s bionic body can bend, fold, lift, manipulate, and reach out and touch with advanced dexterity. UBTECH says Walker’s gen4 industrial dexterous hands provide 33-pound payload handling and around 162 degrees of waist rotation in a workspace up to six feet wide.

UBTECH’s Walker S2 robot can swap out its own battery. One is seen here inserting a battery into itself at an automotive plant in China. [Video still: UBTECH]

Work breaks? Lunch? Vacations? Not this guy. In fact, UBTECH says Walker S2 is the world’s first humanoid robot to achieve “3-minute autonomous battery swapping,” enabling continuous 24/7 operation. When the robot senses its battery is running low, it simply walks over to a banked battery station and swaps out its own battery—then gets right back to work, as seen above.

UBTECH says it plans to manufacture 10,000 units annually by 2027, according to the South China Post, with Chief Branding Officer Michael Tam predicting that production costs for a humanoid robot could fall below $20,000 by 2030.

You can see a video of the Walker S2 in action on this UBTECH LinkedIn post.

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.