NuZee, a Richardson-based innovator in coffee technology and co-packer of single serve specialty coffee formats, has partnered to market a new, patented Japanese technology—TiMELESS—in the U.S. and Mexico.

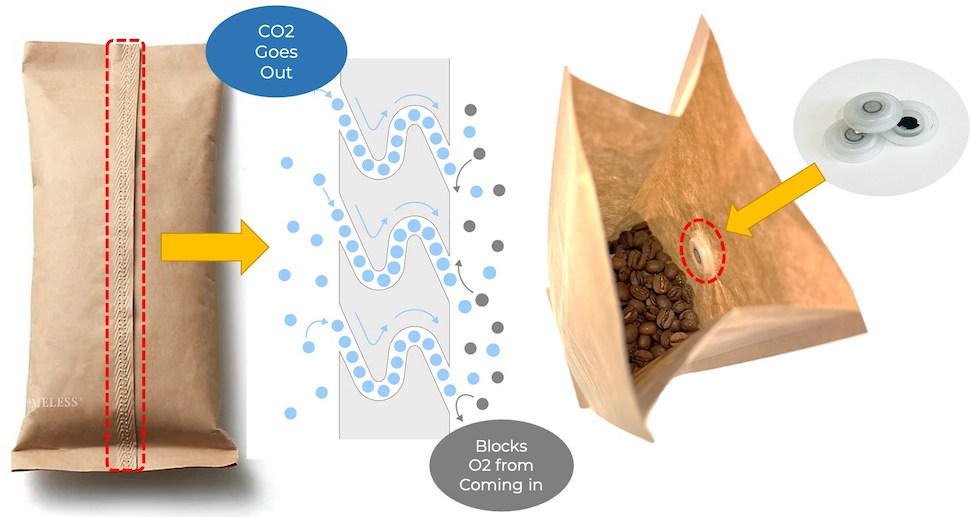

TiMELESS is a new flexible film sealing technology that eliminates the need for one-way plastic degassing valves, which are very common in the coffee packing, pet food, and various other industries, NuZee says.

“TiMELESS technology has the dual advantage of helping to ensure optimum freshness in our U.S. and Mexico coffee products while simultaneously contributing to the reduction of plastics and providing more eco-conscious coffee to the world,” NuZee CEO Masa Higashida said in a statement.

Reducing plastic waste in a growing market

Plastic one-way degassing valves. [Photo: NuZee]

What’s a degassing valve? It’s a one-way vent that allows coffee beans and ground coffee to slowly release carbon dioxide and other volatile gases from the bag, without coming into contact with the air outside.

TiMELESS was developed in 2018 by MIB Co., Ltd., a Tokyo-based trading company specializing in the production and sale of packaging and packages, in collaboration with Nagase & Co. Ltd., one of Japan’s largest publicly traded companies.

NuZee said that as part of the joint marketing agreement, it will introduce TiMELESS technology and packaging using the TiMELESS technology to its customers in the U.S. and Mexico.

According to Nagase & Co., Ltd., the amount of one-way degassing valve consumption in North America was 1.85B per year as of 2022 and is expected to increase to 2.5B per year by 2028.

NuZee, MIB and Nagase are working together to reduce that number to as close to zero as possible. The global coffee one-way valve market is estimated to be worth $274 million annually and is expected to climb to $366 million by 2028, NuZee said.

Currently, when packing roasted coffee, one-way plastic valves are commonly used for degassing, which allows the coffee to stay fresher, longer, NuZee said.

How TiMELESS works

TiMELESS’s proprietary degassing technology works by imprinting the proprietary TiMELESS pattern onto coffee bags, allowing only the air inside the package to escape while keeping out external air.

The TiMELESS pattern, consisting of miniature holes, coupled with the method of impression stamped onto the film, makes this technology function.

In North America, NuZee said roughly 1.85 billion plastic valves are consumed annually, and typically make their way to landfills.

By utilizing the TiMELESS technology in place of plastic valves, NuZee said it believes overall plastic waste will be reduced.

“The first time I saw a plastic valve on coffee bag was 12 years ago. I felt uncomfortable about why the valve was attached, so I started developing a technology to remove the valve. That’s TiMELESS,” MIB Co. CEO Toru Watanabe said in a statement. “However, it was not so easy to invent a structure to replace the valve, and we continued try and error for 12 years. Finally, TiMELESS became technology that gives degassing function, and keeps low oxygen level.”

NuZee said it is in discussions with some of the top coffee manufacturers in the U.S. and Mexico to implement TiMELESS bag sealing technology.

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.