A Dallas CEO is taking tech made for the battlefield to help first responders save lives on the home front.

Compression Works, a medical device company, is raising new funding to further commercialize what CEO Scott Dodson calls the “Swiss Army knife of tourniquets.”

“Necessity is the mother of invention, and this is what really spurred the initial activity for our technology,” Dodson told Dallas Innovates. “The tourniquet was really developed out of necessity on the battlefields of Iraq and Afghanistan—a technology that would stop the most significant bleeds at the point of injury and allow them to stabilize the patient and get them to a point of definitive care.”

Compression Works CEO Scott Dodson [Photo: Morton Visuals]

Stopping the bleeding

Unlike traditional tourniquets, which Dodson said work for superficial wounds and those on extremities, Compression Works’ device—called the abdominal and aortic junctional tourniquet-stabilized (AAJT-S)—can be used to stop bleeding on areas like the shoulder, abdomen, and pelvis.

The device can be easily carried by first responders for use in the field. In a five-step process, they position the device, fasten it to a patient, and inflate a conical bladder that inserts itself in the body to stop hemorrhaging.

Dodson said his company is also exploring potential uses to help stabilize heart attack victims en route to the hospital and to stop postpartum hemorrhage, which he noted is a leading cause of maternal deaths outside the U.S.

“The genius behind our device is that it is also a belt type system that wraps around the patient in five different parts of their anatomy,” Dodson said. “When you put pressure into this bladder, it literally inflates in this cone shape into the body, pressing against the vessels and shutting off the bleeding like turning off a faucet.”

Battlefield origins

Compression Works was co-founded in 2008 by Dr. John Croushorn and Dr. Richard Schwartz so the device could be used by military special forces on the field. Both cofounders are veterans, and they received FDA approval for the device within eight days. At that time, the device was picked up by special operations forces like the Navy SEALs and Army Rangers.

Dodson says that until about two years ago, the company was largely run as a passion project. Then the decision was made to scale the business in an effort led by Dodson, who has experience at large tech firms and numerous venture-backed startups. While the company has historically been based in Alabama, Dodson is based in Dallas and says his company plans to continue its growth from the North Texas region.

“We’ve really been pivoting the company over the last two years, standing up distribution, not only coast to coast in the United States to call on a significant opportunity in the EMS and tactical law enforcement markets, but also in international markets around the world,” Dodson said.

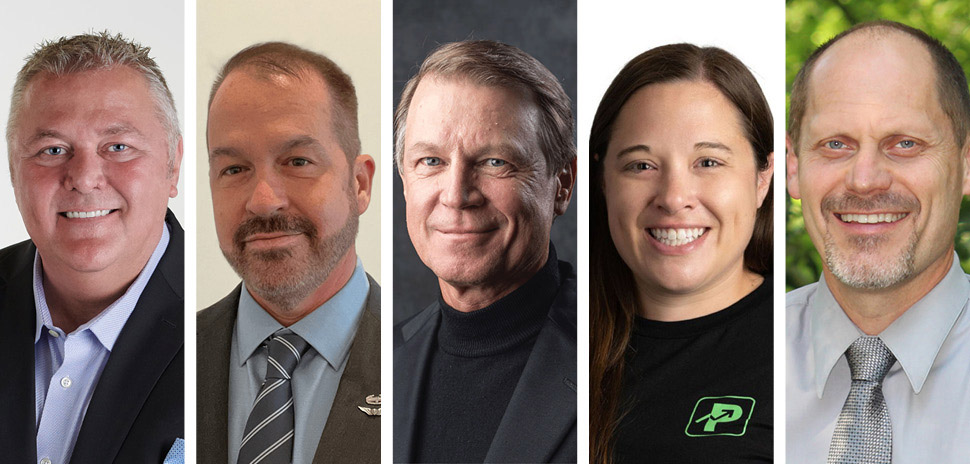

The Compression Works team, left to right: Scott Dodson, President/CEO; Dr. John Croushorn, Co-Founder/Chief Medical Officer; David Karabinos, VP, Corporate Development; Callee Newhouse, Controller; and Dr. Richard Schwartz, Co-Founder Clinical Advisor

Compression Works seeks to raise $2 million

Since the decision to scale, rather than sell off assets or spin off the technology, Compression Works has expanded its presence and is now used in 18 countries and is adding about five to six new countries per quarter, Dodson said. The company currently works with five regional distributors across the U.S., all focused on the first responder space. The device is currently being used by a number of large fire departments and EMS organizations, including in Dallas, New York City, and the Miami-Dade area.

Dodson said Compression Works is set to see more than $2.5 million in revenue this year, with revenue projected to grow to more than $25 million over the next two and a half years. All of that has been done with only a $320,000 pre-seed round. This year, the company is also on track to sell more devices that it has collectively since its launch.

To help continue its growth trajectory, Compression Works is in the middle of raising a $2 million convertible note, of which Dodson said it has closed about 75%. With the new funding, the company will be bringing on new team members to expand its production capabilities and find new clients in the field.

“We think that the momentum will continue to build on this, given the applicability of this device and the fact that it’s so small and compact,” Dodson said. “It can really drop on to any vehicle or into any medic or paramedic’s go-pack and go along with him to the accident site.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.