General Motors is putting its money where its future is—and one of those places is its huge, bustling plant right between Dallas and Fort Worth.

GM recently announced it’s making a $55 million investment at its Arlington Assembly plant for the new tooling and equipment needed to support future production of Chevrolet, GMC, and Cadillac full-size SUVs. The company plans to begin the renovations later this year.

According to GM officials, the investment in new, state-of-the-art equipment will further enhance manufacturing as a competitive advantage for the automaker, providing the tools and technology for its workforce to continue to roll out high-quality vehicles.

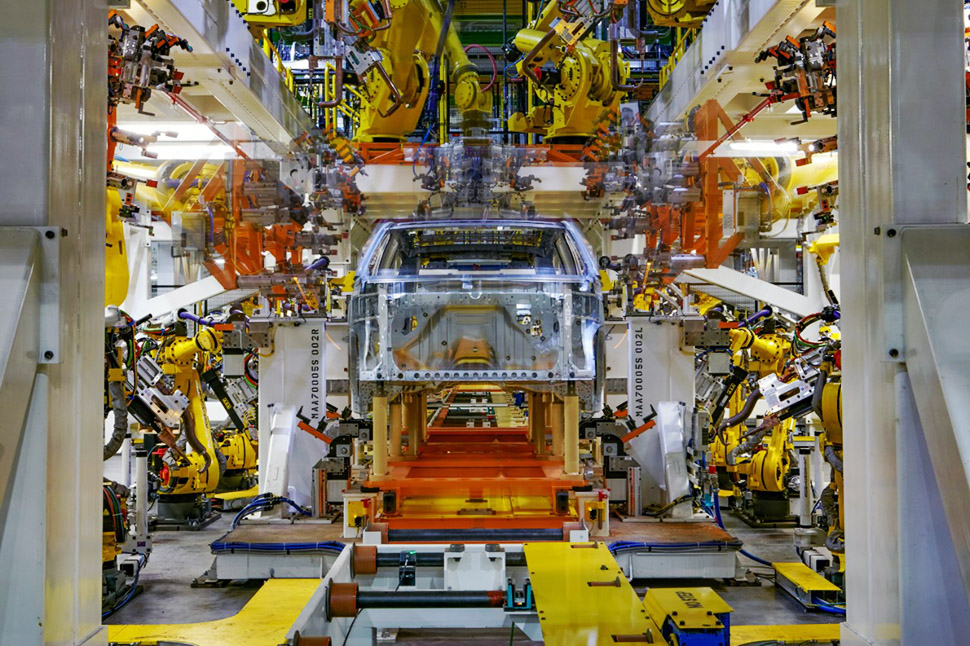

Body assembly of the 2021 Chevrolet Tahoe within the new, 1-million-square-foot body shop at GM’s Arlington Assembly plant. [Photo: GM]

Investment supports GM’s growth strategy

The investment is also meant to support GM’s growth strategy, “including truck and SUV dominance and an all-electric future.” In June, GM announced it will increase its electric vehicle and autonomous vehicle investments from 2020 through 2025 to $35 billion. That figure represented a 75 percent increase from GM’s initial commitment, which was announced prior to the pandemic.

For now, though, the Arlington Assembly plant will continue to assemble gasoline-powered, driver-driven vehicles.

Body assembly of the 2021 Chevrolet Tahoe within the 1-million-square-foot body shop at GM’s Arlington Assembly plant [Photo: GM]

12 million vehicles have been assembled at the plant

GM’s Arlington plant opened in 1954, back when the starting hourly wage for a line operator was $1.78. Today, more than 12 million vehicles have been produced there, including the 12 millionth one assembled earlier this year—a Chevrolet Suburban.

As of June of this year, 5,677 employees work at the plant, which pays more than $1 million in wages every day, according to GM. The company was recently ranked as the 12th largest employer in North Texas by the Dallas Business Journal.

Around 1,200 vehicles are produced at the plant daily. Its production line currently runs 24 hours a day, six days a week—producing one vehicle almost every 60 seconds.

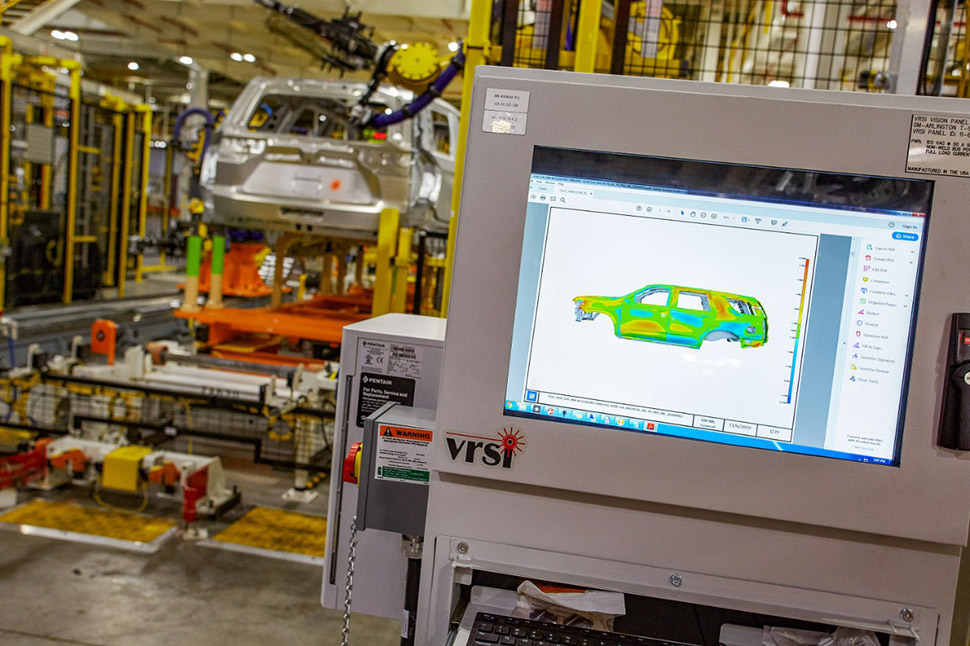

Inspection on the new underbody sealing line at GM’s Arlington Assembly plant. [Photo: GM]

Investment follows earlier $1.4B expansion

GM’s new investment follows a $1.4 billion, 1.6 million-square-foot expansion of the Arlington Assembly plant that began in 2015. That massive investment included a new, 1-million-square-foot body shop and a 600,000-square-foot expansion of the paint shop.

Body inspection of the 2021 Chevrolet Tahoe prior to painting at GM’s Arlington Assembly plant.

High-tech improvements in that expansion included new, high-precision camera- and laser-based inspection systems that delivered more sophisticated quality checks for GM’s SUVs.

An all-new quality audit station in the Arlington body shop uses robotic laser scanners to produce a highly detailed color map of body assemblies for tolerance analysis.

“Everything we do at Arlington Assembly is focused on building better vehicles for our customers,” said Bill Kulhanek, plant executive director at Arlington Assembly, in a 2019 statement about the $1.4 billion expansion. “This strategic expansion brings the latest in manufacturing and inspection technologies, while adding procedures designed to improve the quality and durability of the Tahoe and Suburban.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.