North Texas-based Moonshot has a trifecta in motion. New manufacturing capacity, a national AI platform, and a deeper push into energy infrastructure are all underway.

[Rendering: Moonshot]

The startup is relocating its headquarters from Denton to Lewisville this month, significantly expanding its operational footprint. The new 541,265-square-foot global headquarters and manufacturing hub is designed with dedicated room to scale as production ramps up.

The site anchors the company’s production of QAI Moon AI Pods—modular compute units designed for edge computing—and features 505,265 square feet of advanced manufacturing space alongside 36,000 square feet of Class A offices.

The expansion involves a $50 million investment, according to the Dallas Business Journal. In its official announcement, Moonshot describes the new campus as the next step in its mission to serve the “accelerating needs of Al, hyperscale, and energy infrastructure,” calling the facility a “launchpad for the future.”

Joint venture: A national infrastructure platform

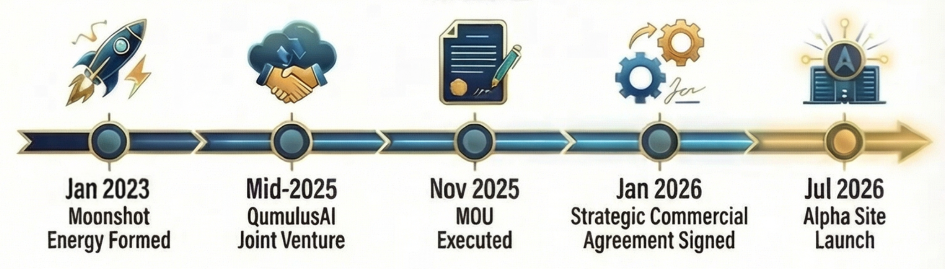

On Jan. 15, Moonshot announced what it calls a first-of-its-kind national platform that combines Internet Exchange Points—known as IXPs—with distributed AI Pods.

Moonshot and its partner QumulusAI, operating together as QAI Moon, have teamed up with IXP.us to deploy a national distributed AI compute and internet exchange platform.

Moonshot will design and build the pods, which make up compute clusters designed to bring low-latency AI inferencing to smaller cities and university campuses across the United States. Each pod is a 2,000 kW modular unit.

[Image: Moonshot]

The pods operate as a distributed cloud platform, and GPU-as-a-Service is the operating layer that turns the AI Pods into a usable platform.

Moonshot formed Moonshot Energy in 2023, a dedicated GPU-as-a-Service operating company, to expand beyond manufacturing into AI compute infrastructure. QumulusAI handles orchestration and workload delivery across the national network.

“This partnership represents the physical convergence of power, compute, and interconnection at the exact point where AI demand is moving,” Ethan Ellenberg, CEO and co-founder of Moonshot, said in a statement.

The rollout begins with 25 initial sites, including an “alpha site” at Wichita State University planned for July. The partners aim to scale to 125 sites nationwide over the next five years.

[Image: Moonshot]

The ‘agnostic’ edge

Moonshot is building a carrier-neutral platform, meaning it isn’t tied to a single internet service provider. Instead, the model allows developers and enterprises to access computing power without being locked into one vendor’s ecosystem.

By placing AI Pods directly at IXPs—the physical locations where internet traffic converges—the company is positioning compute closer to users, reducing the distance data must travel.

Ellenberg said pairing Moonshot’s modular electrical and AI infrastructure with IXP.us’ interconnection model and QumulusAI’s GPU platforms creates a repeatable national architecture designed to deliver ultra-low-latency AI.

[Image: Moonshot]

Solving the ‘latency gap’

Most AI workloads today run in centralized hyperscale data centers, the company said. While those facilities provide scale and efficiency, their distance from end users can introduce delays—an issue for real-time applications such as autonomous systems or medical diagnostics.

“This partnership allows us to place GPU compute directly at the network edge, where data moves and decisions happen,” Moonshot said of the joint venture. The goal is to offer a capital-efficient alternative to centralized AI infrastructure that remains open to network operators and enterprises.

“AI workloads are increasingly inference-driven, latency-sensitive, and distributed, but the infrastructure hasn’t kept pace,” said Mike Maniscalco, CEO of QumulusAI. “Together, we’re building a national platform that makes high-performance AI compute practical and scalable beyond hyperscale data centers.”

Hunter Newby, co-CEO of IXP.us, said the partnership enables scalable compute infrastructure adjacent to network-dense facilities. “We could not be more pleased to help build what will become foundational infrastructure for the AI economy,” he said.

Building through the Bitcoin ‘Wild West’ to AI precision

Founded in 2021, Moonshot grew out of the founders’ experience in cryptocurrency mining before expanding into data center and AI infrastructure. Ellenberg and co-founder Johnny Larsen originally launched the company to self-mine Bitcoin, but soon identified a broader opportunity in the electrical systems and cabling required to support high-powered data centers.

They pivoted to designing and manufacturing UL-certified electrical systems, a move that quickly gained traction. In a 2024 podcast, the founders shared that their “wild ride,” which included a $26 million revenue month in January 2024, proved the appetite for their specialized hardware.

The Dallas Business Journal reported that Moonshot’s revenue has grown more than 3,800%, fueled by demand from customers including Foxconn, Google, Anthropic, TeraWulf, and Fermi America.

Under its Moonshot Electrical & Controls unit, the company designs and manufactures switchboards, control panels, and modular electrical units used in data centers, Bitcoin mining operations, and AI computing facilities. It also distributes power transformers for utility, solar, and industrial applications.

From pandemic side project to half-million-square-foot campus

The road to Lewisville was paved with pandemic grit. Ellenberg started Moonshot as a “side hustle” after being laid off in 2020.

“I thought I was simply starting a small side hustle to make ends meet,” Ellenberg said on Linkedin. “I never imagined it would grow into what it is today in such a short amount of time.”

By 2022, the company was operating out of a 5,000-square-foot warehouse and outgrew it. “Just two years ago, we were somehow building 200 MW worth of electrical infrastructure out of a 5,000-square-foot warehouse,” Ellenberg added.

“To keep up with orders, we’ve had teams building panels in our parking lot—literally taking the work outside because we outgrew our walls faster than we could find new ones,” he wrote.

Ellenberg described it as a reflection of the company’s “find-a-way” culture. “It’s a testament to the grit of this team,” he wrote. “They don’t wait for the ‘perfect’ environment to get the job done; they find a way.”

Now, as the company moves into its new headquarters and manufacturing site in Lewisville, “we finally have a launchpad that matches our ambition,” he said. “In 2026, glory to God, we will 10X again.”

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.

![Social entrepreneur Byron Sanders, a former nonprofit exec, is CEO of Arete Health, launched in January 2025. [Photo: Michael Samples]](https://s24806.pcdn.co/wp-content/uploads/2025/10/27_ByronSanders-STEM-STEAM-STREAM-970_courtesy_Oct2019-1.jpg)