Addison-based Firehawk Aerospace is scaling up its breakthrough 3D-printed rocket propulsion technology with fresh backing from both U.S. and European defense investors.

Firehawk, which specializes in advanced energetics and solid rocket fuel, has secured a strategic investment from Presto Tech Horizons as part of its oversubscribed $60 million Series C round. The fund is a joint venture between Prague-based Presto Ventures and Czechoslovak Group (CSG), a global industrial and defense prime. Firehawk said the partnership aims to strengthen Europe’s ability to locally source critical elements of the munitions supply chain.

The round was led by 1789 Capital, a U.S. fund co-founded by Donald Trump Jr., marking its first major foray into defense technology.

The startup, founded in 2019 by Will Edwards, Steve Edwards, and Ronald Jones, said the European investment aims to strengthen Europe’s ability to locally source critical elements of the munitions supply chain, boosting resilience and ensuring sustained defense readiness for NATO and allied forces.

‘The core of combat power’

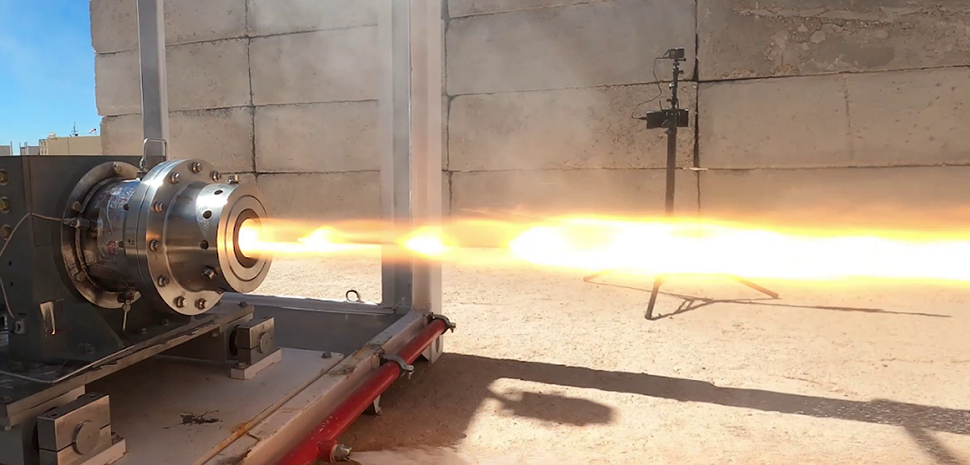

A 2023 Firehawk rocket engine test. [Photo: Firehawk Aerospace]

“The conflict in Ukraine proves that while drones give warfighters a decisive edge, munitions like missiles and rockets are the core of combat power,” Firehawk CEO Will Edwards said in a statement. “A supply chain is only as strong as its weakest link, and propellant and energetics production are the biggest constraint on missile, rocket, and artillery manufacturing.”

Edwards said enabling the European defense industry to produce these weapons “quickly and at scale” is the core of Firehawk’s mission. “We’re proud to partner with Presto Tech Horizons and CSG to help bolster the European energetics supply chain and ensure our allies can fuel the production of key defense equipment,” he added.

The fund behind the investment is built on a rare alliance between a venture capital firm and a defense prime and creates a bridge between innovation and industry, according to Firehawk. The company said the alliance between a venture firm and a defense prime represents a new model for scaling emerging defense technologies—accelerating adoption and deployment across allied industrial bases.

3D printing speeds production

Firehawk is pioneering what it says is the world’s first scalable use of 3D printing for propellant and solid rocket motors—enabling faster, safer, and more flexible production of advanced energetics. The same advances in propellant design and manufacturing that make rocket motors more efficient, the company said, can also be applied to artillery charges—”unlocking rapid, reliable, and scalable ammunition production.”

Today’s rocket propellant is typically cast into large molds and cured—a slow, hazardous, and inflexible process that can take up to two months. Firehawk said it replaces a decades-old method with additive manufacturing, using 3D printing to create complex grain geometries.

By applying novel additive techniques and using relatively inexpensive commercial off-the-shelf equipment, the company said it can reduce per-unit production times by more than 99% compared to traditional methods. That efficiency, Firehawk added, makes motors safer to produce, quicker to scale, and easier to adapt across weapon systems—ultimately transforming the energetics supply chain.

‘Important for Europe’s defense resilience’

“The current geopolitical situation underscores the need to invest in innovative defense technologies,” Michal Strnad, board chair and owner of CSG, said in a statement. “Firehawk can play a crucial role in the future of not only rocket propulsion but also ammunition production. This innovative project can strengthen cooperation between leaders of the American and European defense industries.”

Opportunities for industrial application of Firehawk’s technologies are already being explored.

“Since the early 2010s, scientists and engineers have explored 3D printing as a way to unlock faster, safer, and more flexible solid propellant production,” Matej Luhovy, newly appointed partner at Presto Tech Horizons, said in a statement.

Firehawk, Luhovy said, is the “first to truly deliver on that promise.”

The company’s technology “doesn’t just speed up how propellants are made—it fundamentally reshapes the supply chain for missiles and rockets,” he said. “That’s why this partnership is so important for Europe’s defense resilience.”

Funding and facilities

While the amount of the investment from Presto Tech Horizons was not disclosed, Firehawk described it as a significant commitment to its mission. The round supports the company’s transition from R&D and prototyping to full-scale production.

In addition to 1789 Capital, participants in the round include Draper Associates, Decisive Point, Stellar Ventures, and other leading VCs. As the only European investor, Presto Tech Horizons will help bring Firehawk’s energetics technology closer to allied defense users across Europe.

Recently landed $4M AFWERX contract

Firehawk Aerospace recently announced it landed a $4 million Tactical Funding Increase contract from the U.S. Air Force to advance its 3D-printed rocket propulsion technology. The award comes through AFWERX, the Air Force’s innovation arm that partners with startups to accelerate next-generation defense capabilities.

The company said the new funding will support the design and hot-fire testing of extended-range motors engineered for greater performance and adaptability.

Strategic growth in Oklahoma

In May, Firehawk received a pivotal land and capital investment from the State of Oklahoma and federal leaders including Gov. Kevin Stitt, U.S. Sen. Markwayne Mullin, U.S. Rep. Tom Cole, and Rep. Trey Caldwell.

The package includes the transfer of 320 acres near Fort Sill in Lawton, along with $22 million in state and federal funds to build a 40,000-square-foot manufacturing facility with specialized test infrastructure and equipment.

Firehawk designs its products at its Dallas-area headquarters. It performs static fire and flight tests at two facilities in West Texas, including a 30-square-mile launch range.

Quincy Preston contributed to this report.

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.