Dallas-based Texas Instruments has begun production of gallium nitride (GaN)-based power semiconductors at its factory in Aizu, Japan. When coupled with its existing GaN manufacturing in Dallas, TI now will internally manufacture “four times more GaN-based power semiconductors,” TI announced.

“Building on more than a decade of expertise in GaN chip design and manufacturing, we have successfully qualified our 200mm GaN technology — the most scalable and cost-competitive way to manufacture GaN today — to start mass production in Aizu,” Mohammad Yunus, TI’s SVP of Technology and Manufacturing, said in a statement. “This milestone enables us to manufacture more of our GaN chips internally as we grow our internal manufacturing to more than 95% by 2030, while also sourcing from multiple TI locations, ensuring a reliable supply of our entire GaN portfolio of high-power, energy-efficient semiconductors.”

GaN is a silicon alternative

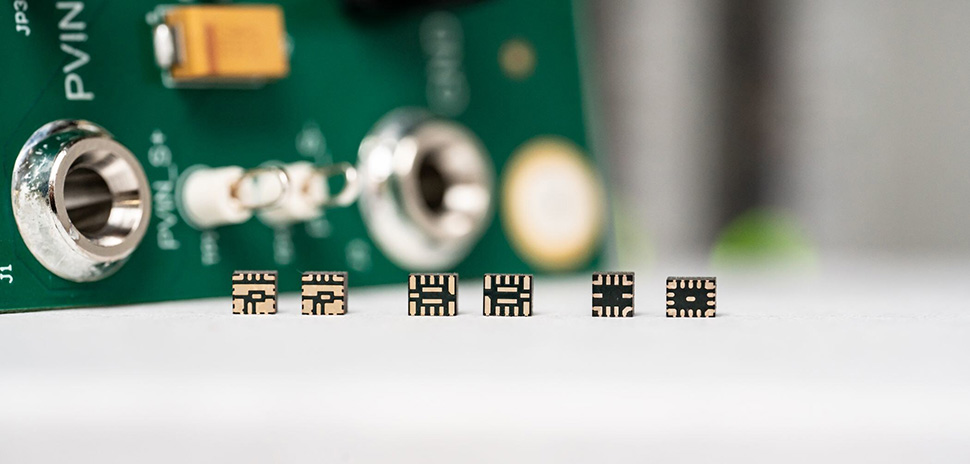

TI said that as an alternative to silicon, GaN is a semiconductor material that offers benefits in energy-efficiency, switching speed, power solution size and weight, overall system cost, and performance under high temperatures and high-voltage conditions. It said that GaN chips provide more power density, or power in smaller spaces, enabling applications such as power adapters for laptops and mobile phones, or smaller, more energy-efficient motors for heating and air conditioning systems and home appliances.

TI noted that it currently offers the widest portfolio of integrated GaN-based power semiconductors, ranging from low- to high-voltage, to enable the most energy-efficient, reliable and power-dense electronics.

“With GaN, TI can deliver more power, more efficiently in a compact space, which is the primary market need driving innovation for many of our customers,” Kannan Soundarapandian, VP of High-Voltage Power at TI, said in a statement. “As designers of systems such as server power, solar energy generation and AC/DC adapters face challenges to reduce power consumption and enhance energy efficiency, they are increasingly demanding a reliable supply of TI’s high-performance GaN-based chips. TI’s product portfolio of integrated GaN power stages enables customers to achieve higher power density, improved ease of use and lower system cost.”

Benefits of GaN technology

TI said that with its proprietary GaN-on-silicon process, more than 80 million hours of reliability testing, and integrated protection features, TI GaN chips are designed to keep high-voltage systems safe.

The company said that by using the most advanced equipment available for GaN chip manufacturing today, TI’s new capacity enables increased product performance and manufacturing process efficiency, as well as a cost advantage.

More advanced, efficient tools used in TI’s expanded GaN manufacturing can produce smaller chips, packing even more power, the company added. This design innovation can be manufactured using less water, energy, and raw materials, and end products that use GaN chips enjoy these same environmental benefits.

Texas Instruments said the performance benefits of its added GaN manufacturing also enable it to scale the company’s GaN chips to higher voltages—starting with 900V and increasing to higher voltages over time, furthering power-efficiency and size innovations for applications like robotics, renewable energy, and server power supplies.

TI’s expanded investment includes a successful pilot launched earlier this year for development of GaN manufacturing processes on 300mm wafers. The company said its expanded GaN manufacturing processes are fully transferable to 300mm technology, positioning TI “to readily scale to customer needs and move to 300mm in the future.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.