When the digital revolution upended the traditional printing business, many companies were forced to evolve or face extinction.

OKI Data Americas has thrived on innovation for decades, whether it was leading the way with LED printing or developing more efficient printing capabilities.

So, when corporate printing needs started declining the subsidiary of the Tokyo-based company, which moved its Americas headquarters to Irving earlier this year, made a conscious effort to find new areas of business.

“We want to find a market where our technology can become a disruptive leader.”

Matt Davies

“Major printing companies all have the same problem, they’re printing less,” said Matt Davies, national sales director for OKI Data Americas. “As mobile technology advances, they stopped printing. What can we do with this technology that’s innovative and go into a new market? We want to find a market where our technology can become a disruptive leader.”

For Davies, the answer is simple: food, shelter, clothing, and medicine.

[Screenshot via Impressions Magazine]

“There’s certain things that never go away,” Davies said. “This is going to be here for the rest of my lifetime.”

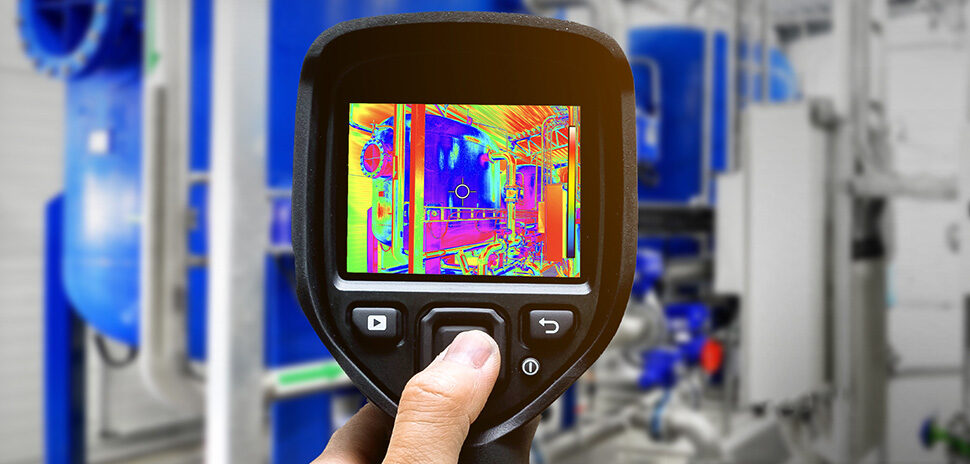

OKI Data is finding potential business with labeling on food and medicine, for example. Perhaps its biggest innovation has come from its garment printing technology, which allows graphic transfers onto T-shirts, fleeces, and other clothing.

OKI DATA PRINTER ENABLES HEAT TRANSFERS ON MORE DELICATE FABRICS

One of its printers, the OKI DataPro8432WT, recently made headlines for transferring a complex color image onto a fleece garment that made the cover of Impressions magazine.

It’s groundbreaking because the printer sets at a lower temperature, meaning designs can be applied to polyesters and other fabrics, something that hasn’t been difficult before. Traditional higher temperature printers would ruin those clothes.

Here’s a YouTube video that demonstrates the technology:

“Heat transfer had a bad reputation when we started,” Davies said. “Lots of shirts got thrown out because they weren’t consistent. Our innovations have expanded dramatically the capabilities of what these people are able to do. Now, I have the technology to allow a decorator to decorate almost anything. That opened up the world to a lot of things.”

The printer also is more efficient and requires less maintenance and cleaning.

“Now, I have the technology to allow a decorator to decorate almost anything.”

Matt Davies

OKI Data sells the printers while also offering customer service and tech support to its clients.

The company actually has four garment printers on the market right now for various applications, including the ability to print in neon colors.

OKI DATA GETS $895K INCENTIVE FOR MOVE TO IRVING

Earlier this year, OKI Data moved from New Jersey into a 15,000-square-foot office in Irving that has about 100 employees now with additional relocations and new hires planned. OKI Data worked with Irving and state officials, securing a $895,000 grant from the Texas Enterprise Fund.

Though Davies is based in New Jersey, OKI Data has dedicated the first floor of the Irving headquarters to a Technology Solutions Center where the cutting-edge work continues. From there, OKI Data will run its operations in North and South americas.

![]()

Get on the list.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.

And, you’ll be the first to get the digital edition of our new Dallas Innovates magazine:

The annual edition publishes in January