A team of Garland High School student researchers spent their summer at SMU’s Lyle School of Engineering, trading textbooks for buckets of Dallas soil, mixers, and compactors. Their task: help design a low-cost, energy-efficient building material that could support affordable housing locally and abroad.

Working with Brett Story, associate professor of civil and environmental engineering at SMU, the students tested compressed earth blocks—made from local soil, water, and a small amount of cement. Unlike traditional masonry, the blocks aren’t fired in kilns, lowering costs and avoiding the air pollution caused by brick production. Despite that, their strength and long-term durability are comparable.

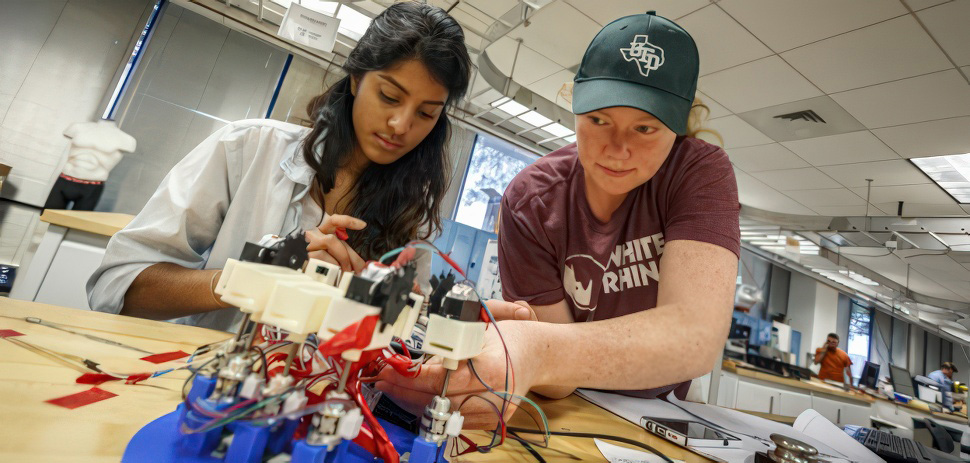

Garland students working on the building blocks at SMU. [Photo: SMU]

Commercial potential

Compressed earth blocks are already in use globally as a lower-cost substitute for concrete and brick. SMU’s work focuses on refining recipes with Dallas soil and testing for strength and reliability—an essential step if the method is to gain wider adoption.

The approach could appeal to developers, contractors, and housing authorities looking for affordable, locally sourced materials that support both sustainability goals and bottom lines.

Brett Story, associate professor of civil and environmental engineering [Photo: SMU]

Hands-on workforce training

Over six weeks, Garland students learned the chemistry of soil, the math behind structural design, and the importance of standardized testing. In July, they saw the payoff: scooping Dallas soil into a mixer, molding and compressing the blend, and producing sturdy blocks that dried into usable materials.

“They learned how engineering is used to solve interesting problems, they learned they can do difficult things, and they learned the best way to solve a problem is to get people working together,” Story said in a statement.

For students, the hands-on approach connected classroom lessons to real-world impact. “I can see how all the work ties in together to create something that will help the world in a good way,” said Garland junior Collin McCorkle-Skees.

Why it matters

The project highlights the potential of compressed earth blocks as an environmentally friendly alternative to concrete and masonry, while also giving North Texas students a direct role in solving global and local housing challenges.

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.