Could the future of farming be under the sea? From its base in Noli, Italy, a startup called Nemo’s Garden is growing crops in air-filled biospheres anchored to the sea floor. By harnessing the ocean’s environmental benefits—temperature stability, evaporative water generation, CO2 absorption, abundant oxygen, and pest protection—they aim to prove the viability of cultivating herbs, fruit, and vegetables underwater.

So why reach out to Plano-based Siemens Digital Industries Software, whose HQ could hardly be more land-locked? Nemo’s needed predictive, machine-learning insights to help them monitor the biospheres remotely, process automation, and “massively accelerate” their innovation cycles toward more rapid industrialization and scale.

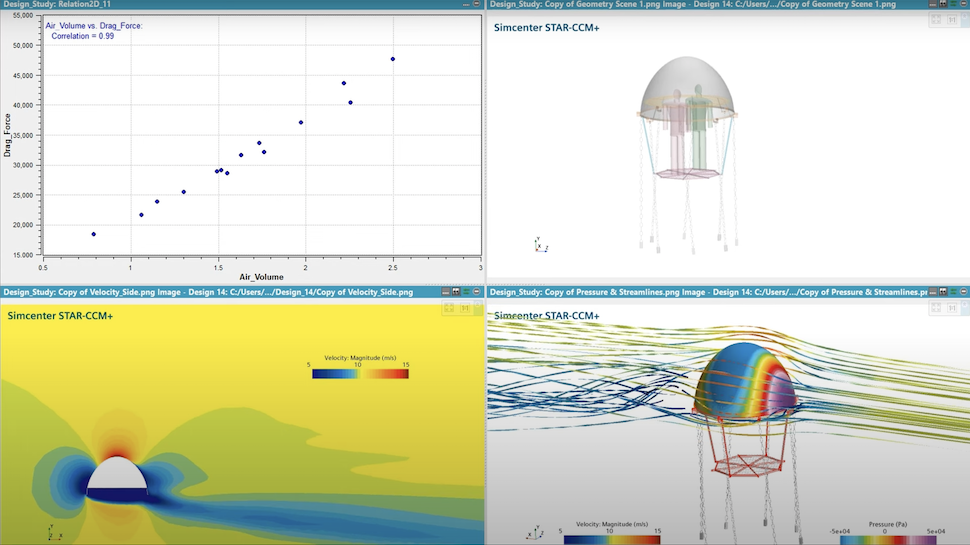

To help achieve this, Siemens created a digital twin of Nemo’s biosphere. Siemens’ Simcenter STAR-CCM+ software is used to monitor plant growth as well as the environmental conditions within Nemo’s “sub-aqua biosphere” domes.

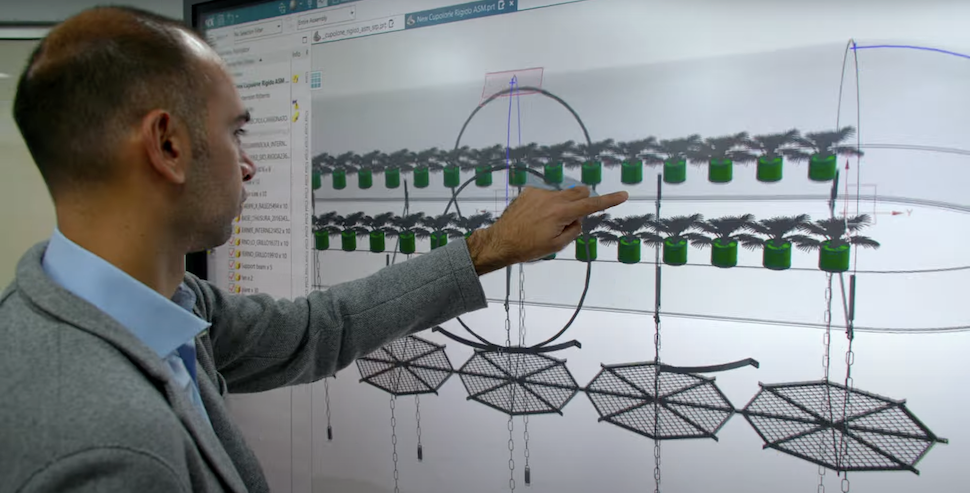

“Nemo’s Garden is a one-of-a-kind system and we need to adapt to each environment where it is to be installed,” Nemo’s co-founder Luca Gamberini said in a statement. “If you can model that environment virtually before you start, you can foresee the challenges and address them in the best way.”

Founded by scuba equipment manufacturers

Nemo’s Garden’s biospheres are a unique type of underwater greenhouse, able to harness the positive environmental factors of the ocean to create an environment ideal for crop cultivation.

(Image credit: OceanReefGroup 2022)

If you’re farming undersea, a scuba tank comes in real handy. It turns out Nemo’s Garden was founded last year by a scuba equipment manufacturer—Sergio Gamberini, president of Italy’s Ocean Reef Group—and his son, Luca Gamberini.

Their team of engineers, divers, and scientists has successfully harvested a variety of crops from its prototype biospheres—reporting them to be “nutritionally richer” than traditionally grown versions.

To turn their prototype into a solution deployed worldwide, Nemo’s needed to do a lot more innovation and testing. But limits in their seafloor-use permit and other factors meant they could grow only one harvest per year, requiring perhaps a decade of insights to refine their technology.

That’s where Siemens came in. By building a digital twin of the biosphere, Siemens’ team can simulate the growing conditions within it, the equipment’s impact on the body of water, and the full environment in which the pods are installed.

Now insights can come without ‘diving in’

Siemens’ STAR-CCM+ software was used to develop a digital twin of the Nemo’s Garden biosphere. [Image: Siemens]

By using the digital twin, the Nemo’s Garden team is no longer limited by weather conditions, seasonality, short growing seasons, or limitations on scuba diving to monitor the pods. Biospheres adaptations can be tested in the virtual world, enabling the team to refine the design at a “massively accelerated rate.”

Video still of insights from the digital twin of the Nemo’s Garden biosphere. [Image: Siemens]

“We’ve seen benefits in understanding the flow of water around the shapes of our biospheres,” said Luca Gamberini. “We have a greater understanding of the points of stress on the structure around the biospheres. We also understand how the different interactions of the solar radiation, the temperature and all the physical factors, act on the plants. All thanks to the ability of the digital twin to replicate our system.”

Industrial Edge devices will be connected to actuators

[Video still of Nemo’s Garden from Siemens Software]

In Nemo’s next underwater growing season, Siemens’ Industrial Edge computing devices will be deployed in each biosphere. They will leverage a machine learning algorithm to automatically adjust air circulation, humidity, irrigation and nutritional dosing throughout the season.

“The work we do with startups can amplify the impact they have on the world, aiding in and speeding up innovation,” said Eryn Devola, VP of sustainability, Siemens Digital Industries Software, in the statement. “It’s easy to get excited when you we find a passionate team with human-centered technology that is working to feed people while having a positive impact on the environment.”

You can learn more about the project and see some cool underwater video by going here.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.