Solar power could someday be a no-brainer. Most buildings in America may be powered by panels creating emissions-free energy, when tech advances make solar the clear, affordable, renewable alternative. Flexible solar panels are kicking that up a notch, enabling all kinds of applications including military defense uses.

To make this solar future a reality, some big brains are hard at work now. Including right here in North Texas.

Nanoscale Materials and Devices Lab

The Kaul Research Group at the University of North Texas in Denton is an international leader in 2D materials. Its Nanoscale Materials and Devices Laboratory works on nanoscale materials for low-power, energy-efficient electronics, opto-electronics, sensors, solar cells, flexible and printed electronics, and devices for biosensing and implantable devices. The lab has been a hotbed of advances lately.

Just last month, a team led by Dr. Anupama Kaul, PACCAR professor of engineering at UNT, successfully used additive manufacturing to print inks of 2D perovskites—highly complex molecules used in solar cells to absorb incoming light in a powerful way.

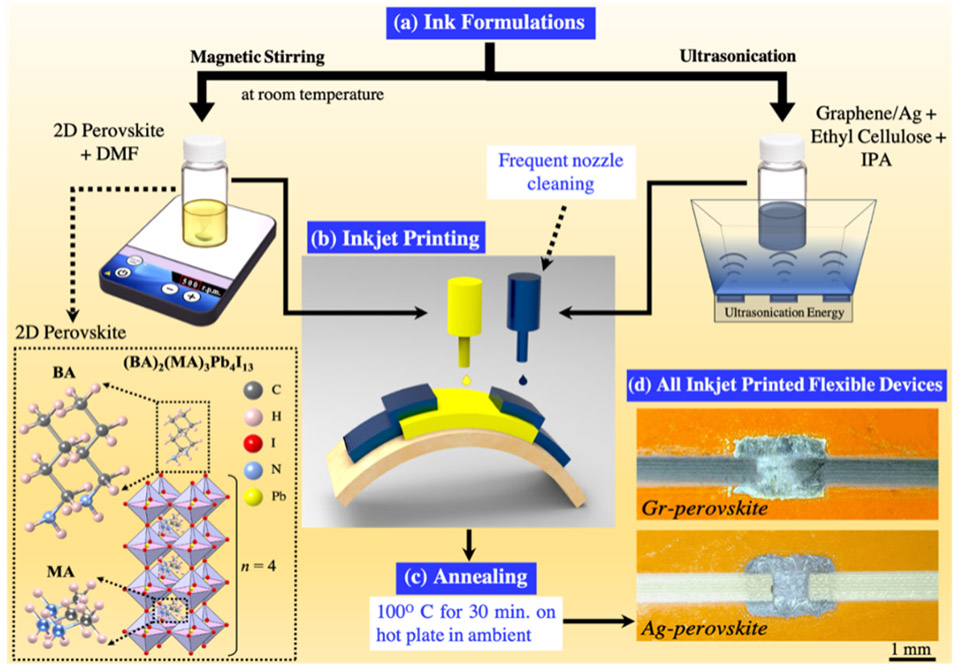

Kaul’s team showed that additive manufacturing can be used to not only inkjet print the 2D perovskites, but also to print the electrical contacts with 2D graphene and silver inks—a huge stride toward more affordable and available flexible solar panels, UNT announced in a statement.

The Nanoscale Lab’s research was funded last year with a $474,000 three-year grant by the Department of Defense’s Office of Naval Research.

University of North Texas Dr. Anupama Kaul, PACCAR Professor of Engineering, Director Nanoscale Materials & Devices Lab and Director PACCAR Technology Institute [Photo: Gary Payne / UNT]

Why perovskites are so hot now

Most people wouldn’t know 2D perovskites from a pair of 3D glasses. But they’re one of the hottest topics in solar power research.

In April, we wrote about the $2.5 million in Department of Energy funding given to Dallas-based Hunt Perovskite Technologies—part of a DOE program dedicated to making perovskite photovoltaic devices commercially available.

As we noted then, Science Daily describes halide perovskites as soft, flexible materials that could make solar cells more efficient at significantly less cost. “Perovskites have the potential to be even more efficient than silicon because less energy is wasted when converting solar energy to electricity,” researchers note. The problem: perovskites are highly unstable.

University of North Texas Dr. Anupama Kaul, PACCAR Professor of Engineering, Director Nanoscale Materials & Devices Lab and Director PACCAR Technology Institute, and her team of researchers have developed a flexible solar cell for the Navy. The cell can be 3D manufactured and then printed onto a substrate using flexible ink. [Photo: Ahna Hubnik / UNT]

Two dimensions, more stability

Kaul explains why two dimensions could make a big difference.

“Traditionally, 3D perovskites have been used for solar cells, but they can be fairly unstable, given their propensity for moisture and oxygen,” said Kaul, who also serves as the director of UTD’s PACCAR Technology Institute, in a statement. “So, our team is addressing those instability issues by leveraging the use of 2D perovskites, which are intrinsically more stable and can also be formed in flexible platforms with additive manufacturing techniques.”

Aircraft carriers, ocean-going drones

“The exciting thing about this research is that it really is a stepping stone to all additively manufactured solar cells for the Navy and the Marine Corps,” Kaul said in the statement. “Once this capability is realized for solar cells, it could change the way the Navy collects and uses electricity toward lightweight photovoltaics in airborne applications, such as ocean-going drones or on aircraft carriers.”

2D Ruddlesden–Popper (2DRP) perovskites have been combined with solution processed electrical contacts like Graphene and Silver to allow a fully inkjet-printed product. This is important because this process doesn’t require the use of expensive clean rooms. [Infographic: UNT]

How Kaul’s team broke through

Kaul and her team’s current efforts involve integrating 2D materials with perovskites for sensors and solar cells. These devices hinge upon mechanisms that convert light to electricity. The electrical contacts play a critical role in collecting as many of the photogenerated carriers within the perovskite absorber layer as possible.

The team’s inkjet printing breakthrough will be used to develop flexible solar cells at a lower cost with additive manufacturing, compared to traditional methods rely on expensive, complex equipment.

“Ink jet printing the electrical contacts to 2D perovskites is not easy since we need to constrain the curing temperature for densifying the films, so the underlying 2D perovskite film does not degrade,” Kaul said. “As a result, lower boiling point solvents were used, but this is very challenging since the nozzles in the printer clog up easily. This issue really required us to think about how we could engineer the process so that we would get the right parameters and results we were hoping for with the 2D perovskites.”

“We found that we were able to create everything through additive manufacturing and demonstrated printed photodetectors on flexible and bendable substrates,” she said.

The UNT team’s current findings have been published in Nature npj 2D Materials and Applications.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.