Siemens Digital Industries Software, the automation and digitalization arm of global tech giant Siemens AG that has its U.S. headquarters in Plano, has launched its Xcelerator as a Service—a move that the company says will build a foundation for a new digital future.

The company says XaaS will offer access to tools, features, and compute resources to organizations, as they need and require them. The solutions are both flexible and personalized, Siemens says, which allows individual users to shape their own workspace.

A core component is maximum and instant productivity.

XaaS is new to Siemens, but Software as a Service isn’t: The company recently laid the cloud-native groundwork for a move to SaaS via a series of in-house developments and acquisitions.

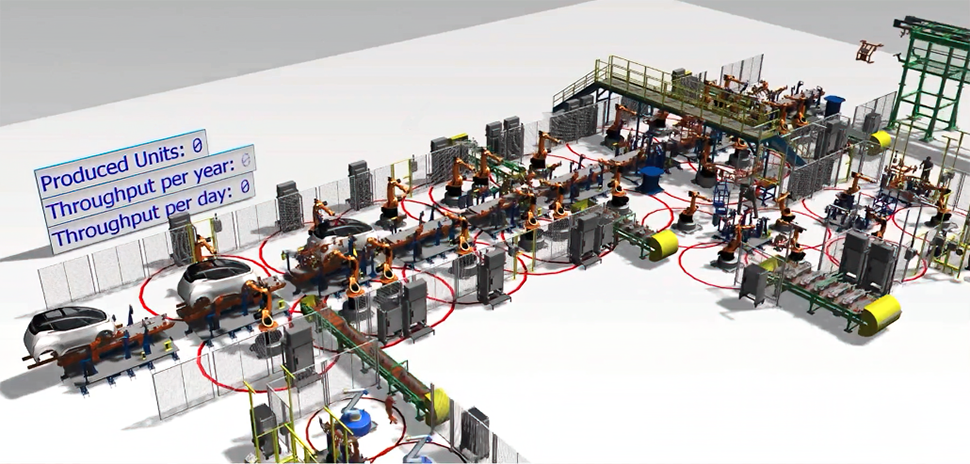

[Video still/Siemens]

In June, President and CEO Tony Hemmelgarn, the Siemens Managing Board, and the leadership team announced the transition of Siemens Digital Industries Software business to an SaaS model.

A large part of that was using the cloud to make Siemens solutions more accessible, flexible, and scalable. Siemens believes “the future of industry is in the cloud.”

Fundamental to this retooling was the company rethinking the way its technology generated value for customers. One key is the previously introduced Xcelerator portfolio, a combination of engineering software, services, and an application development platform.

XaaS is an expansion of Xcelerator; a way for Siemens to “continue to deliver on that strategy.”

Behind the Xcelerator portfolio

Xcelerator combines the industry’s broadest and deepest technologies to make industrial customers’ digital transformation dreams a reality, Siemens says. When Xcelerator was first introduced in 2019, Siemens used it as a way to help companies of all sizes become digital enterprises.

“Digital twin” allows optimization of products and processes

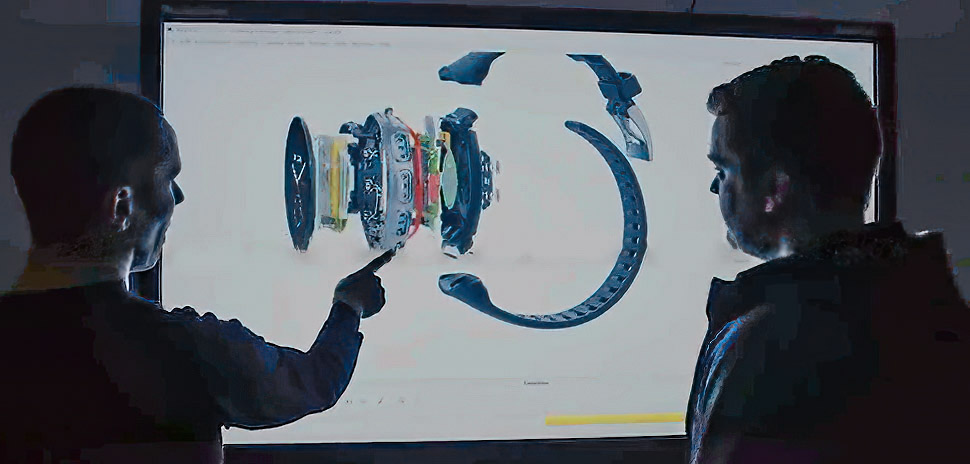

[Video still/Siemens]

Through digital threads, Xcelerator enables product design and manufacturing, while ensuring data is accessible when and where it’s needed. For instance, a comprehensive digital twin allows companies to optimize their products and processes throughout the lifecycle, from creation to production and service.

Siemens Digital Industries Software is rapidly expanding and currently hiring for 500 jobs across the U.S., 50 for openings in Texas.

Driving that growth is the increasing need to improve processes, designs, and simulations by applying a comprehensive digital twin to improve how things work. Digital twin tech can accelerate innovations and successfully manage complexities in the design, production, performance, and durability of heavy equipment.

Siemens says it’s the only company that can offer the toolset, domain knowledge, and usage expertise to deliver a digital twin in the way that manufacturers need.

XaaS will make the Xcelerator portfolio more accessible and to a broader community. Manufacturing organizations will have access to high-performance computing, at any time, from anywhere, on any device.

The cloud removes the need for high performance computing hardware or in-house IT. Teamcenter X is a cloud-native solution that’s part of XaaS.

XaaS applications

At the core of Xaas is the ability to “make new things possible for many types of companies.”

Siemens notes a number of use cases for Xcelerator as a Service.

An automotive startup that wants to introduce their concept to market could leverage XaaS for product development without needing the IT infrastructure to support it. That’s because XaaS offers access to the same toolset leading manufacturing organizations use to build comprehensive digital twins.

Or, XaaS could help a multinational automotive manufacturer increase collaboration across its global supply chain.

“Need to onboard a new supplier because they’ve got break through innovation? Share the data you need to, in a controlled and secure manner simply by typing in their e-mail address and letting the app handle the rest,” Siemens says. “Need to collaborate with your suppliers across the other side of the planet, in virtual reality, with data from other CAD systems? Strap on that headset and let’s get to work.”

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.