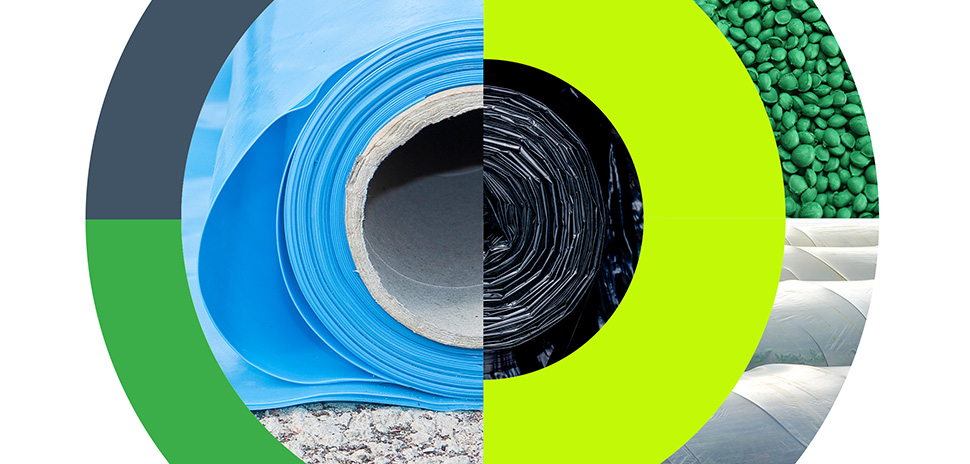

Sustainable materials and recycling solutions innovator Revolution Sustainable Solutions has acquired Norflex Inc., a producer of high-performance agricultural and industrial films, in a strategic move Revolution says will bolsters its capabilities in sustainable agriculture solutions and expands its sustainable stretch and shrink film business.

Revolution is headquartered in Little Rock, Arkansas, and has a strong North Texas presence, including corporate offices in Flower Mound and a manufacturing facility in Mesquite.

The company said its acquisition of Wisconsin-based Norflex brings with it the well-regarded Agriseal silage wrap, a product that “perfectly complements” Revolution’s existing portfolio of sustainable agriculture solutions.

“Integrating Norflex’s Agriseal silage wrap enhances our ability to offer comprehensive, sustainable solutions to the agricultural community,” Revolution President Scott Coleman said in a statement. “This acquisition allows us to further our commitment of helping farmers and agricultural businesses create less waste and increase efficiency.”

The deal’s financial terms were not disclosed.

From farms to homes

Agriseal is known for its durability and efficiency, achieving maximum performance while using less overall material, Revolution said. That aligns with Revolution’s mission to drive sustainability in the agriculture sector, the company added.

Revolution said that for more than two decades, it has served farmers across North America with collection and recycling services for used ag films, converting the material into certified post-consumer recycled resin that can be used to manufacture new film products such as can liners, carryout bags, and stretch film.

Revolution said that Norflex’s robust stretch film business presents significant synergies with its sustainable stretch film division, including technology to expand Revolution’s blown stretch film to complement its current cast film products.

The company said that the combined expertise and resources will enable the production of higher-quality, more sustainable stretch films catering to a wide range of industrial applications.

Revolution said its innovative approach to incorporating certified post-consumer recycled (PCR) content into its products will be enhanced by Norflex’s market reach and technological capabilities, such as requiring less material in their products to reduce overall film use.

Innovations in shrink film

Along with advancements in the agricultural and stretch film sectors, Revolution said this acquisition propels its growth in the shrink film market. The company said that Norflex’s expertise in making high-quality shrink films, combined with Revolution’s expertise in producing consistent postconsumer recycled materials, positions Revolution to offer innovative shrink film solutions with PCR content.

The company said the move aligns with Revolution’s strategy to lead the market in sustainable film production.

Revolution said the acquisition combines two industry leading, like-minded cultures of sustainability and innovation that together will deliver more value to their customers and communities. Revolution said it now is poised to increase product offerings and expand market presence while maintaining the company’s dedication to environmental stewardship.

“As we move forward, our focus remains on developing and delivering solutions to support a sustainable ecosystem and future,” Coleman said.

Diverting plastic waste to food-safe products

Revolution said it uses a unique, circular approach that diverts over 300 million pounds of plastic waste from landfills each year, processing it into high-quality certified recycled resin and putting it back into sustainable products like trash can liners, reusable carryout bags, stretch film, and construction films.

Last year, the U.S. Food and Drug Administration issued a letter of no objection for Revolution’s proprietary recycling method to produce post-consumer recycled, linear low-density polyethylene (LLDPE PCR) made from recycled stretch film for food applications.

The FDA issued a letter of no objection in lieu of approval, certifying that the collection, cleaning, and processing of the post-consumer materials meets its standards for food-safe plastics.

![]()

Get on the list.

Dallas Innovates, every day.

Sign up to keep your eye on what’s new and next in Dallas-Fort Worth, every day.