Fort Worth-based SecureFoundry—a semiconductor manufacturer that serves national security and commercial needs by making specialized semiconductor and additive manufacturing products—says it is “redefining” chip making by launching its Hyper-Beam Array (HBA) lithography system.

Based on a “proven architecture” originally pioneered in Europe, the system is said to be “a new class” of lithography, distinct from both single-beam and multibeam approaches, that operates with tens of thousands of independently controlled beams. The process delivers capabilities “at a scale no electron-beam technology can match,” the company says.

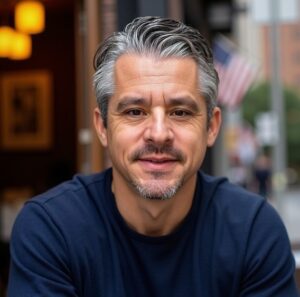

Founded by former Marine Corps Cyber Command technical director

Lex Keen

SecureFoundry was founded in 2016 by CEO Lex Keen, a former technical director for the Marine Corps’ U.S. Cyber Command. At launch, the company focused on manufacturing technology for the U.S. military. Aiming to transform academic innovations into deployable defense solutions, SecureFoundry originally focused on secure, specialized chips for military and intelligence systems. Its aim: “to counter China’s rising technological threats, ensuring a robust, independent U.S. defense infrastructure.”

The company later identified a growing need among universities, startups, and government entities for cost-effective prototyping, short-run manufacturing, and production of obsolete parts. These projects often fall outside the scope of high-volume semiconductor fabrication plants—or “fabs”—due to scale, cost, or production lead times, the company said.

So SecureFoundry stepped in to fill that gap.

It does this by operating a “trusted domestic foundry” that combines traditional and maskless lithography techniques. The company says its flexible model allows developers to test and iterate chip designs quickly, without the high upfront investment in photomasks, thereby reducing time to market.

The approach provides greater access to chip manufacturing without the high costs of traditional foundries, SecureFoundry says, while supporting “domestic microelectronics innovation.”

Helping AI chip designers experiment with rapid design variations

Unlike traditional photolithography, which requires costly masks and has long lead times, SecureFoundry says its HBA lithography system uses 65,000 parallel electron beams to pattern wafers directly. Each beam is independently controlled, with the wafer scanned in two passes, automatically compensating for any missed pattern. This architecture is specifically optimized for mixed-volume manufacturing and security-critical use cases “where flexibility, traceability and repeatability are paramount,” the company says.

“During the system’s characterization, we demonstrated the ability to fully pattern a 100mm wafer in just 15 minutes,” Keen said in a statement. “The HBA tool enables wafer-scale integration, advanced fan-out packaging, and multiple design variations in a single run—delivering unmatched flexibility and faster innovation.”

“The HBA tool allows AI chip designers to experiment with slight design variations across a single wafer, enabling exploration of ‘AI personalities’ and rapid feedback on performance outcomes,” Keen added. “Unlike multibeam systems with only a handful of beams, HBA lithography represents a different class altogether, built for both advanced and legacy nodes, throughput and reliability.”

Aimed at research institutions, defense contractors, and commercial partners

SecureFoundry said its HBA lithography system supports research institutions, defense contractors and commercial partners seeking “agile, onshore solutions.” The system aims to fill a gap in the semiconductor supply chain between design, research and development, and commercial production, enabling highly custom chip designs.

Optimized for nodes between 22nm and 65nm, the HBA system can print on 100mm to 300mm substrates, and can pattern silicon or compound silicon substrates. Its software-defined patterning architecture enables design flexibility, the company said, while built-in die-level traceability and digital provenance address growing requirements around trusted supply chains and device authentication.

That traceability gains extra importance when it comes to national security, Keen noted.

“For defense and security applications, every die must be accounted for,” the CEO said. “This system gives us a fully auditable chain of custody from design to wafer.”

Transitioning manufacturing for “a collaborative win’

SecureFoundry says its HBA system fills a critical void in the ecosystem by removing barriers to entry for both emerging and legacy devices.

“Our approach will create new customers for large, leading-edge fabs,” Keen said. “The HBA lithography system provides access to manufacturing capabilities that are needed to commercialize new chip technologies, allowing companies to build demand and ultimately transition manufacturing toward high-volume fabs. An increase in new technologies demanding high-volume services, enabled by our technology, is a collaborative win for the industry.”

SecureFoundry’s HBA lithography system is operated exclusively within U.S.-based, secure facilities, the company said, ensuring compliance with all defense and export control regulations.

Besides its Fort Worth facility at 1305 Ranchers Legacy Trail, SecureFoundry also has locations in Arbutus, Maryland, and Eindhoven, The Netherlands.